CHAPTER 2

Hardware Modifications

10

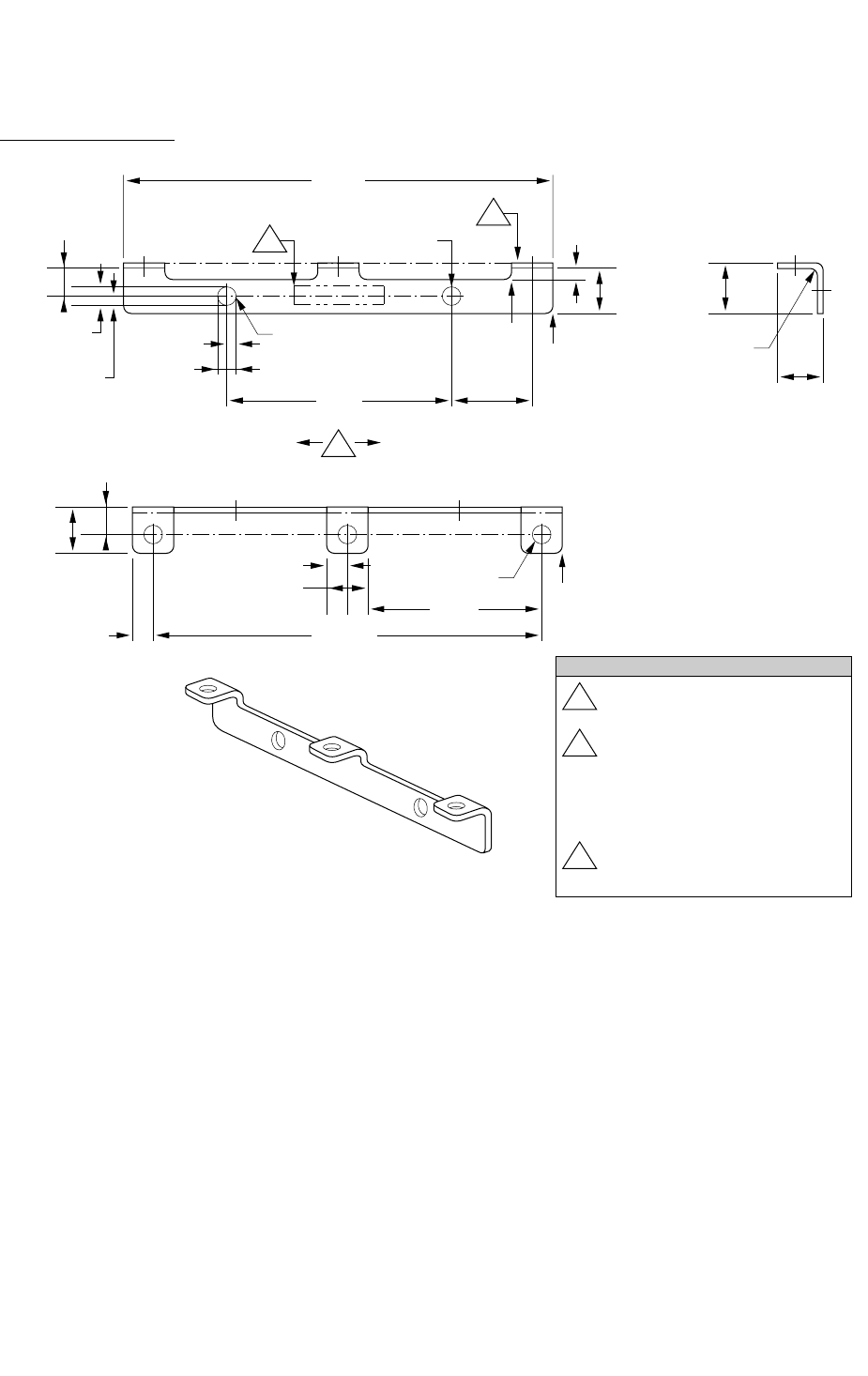

200 MB Hard Disk Drive

Figure 2-2

Bracket for the hard disk drive

2.874"

(73.00mm)

0.299"

(7.60mm)

2x 0.079"

(2.00mm)

0.125"

(3.20mm)

(1.60mm)

0.188"

(4.795±0.125mm)

0.549"

(13.95mm)

1.5"

(38.10mm)

0.082"

(2.10mm)

0.165"

(4.20mm)

2x R full

4x R

0.039"

(1.00mm)

2x R 0.059"

(1.50mm)

C

L

1

3

0 0.125"

(3.200mm)

2

(8.60)

(7.80)

3x R 1.00

2.598"

(66.00mm)

1.299"

(33.00mm)

3x 0.137"

(3.50mm)

3x 0.275"

(7.00mm)

0.137"

(3.50mm)

3x 0.307"

(7.80mm)

0.192"

(4.900±0.125mm)

3x 0 0.118"

(3.00mm)

6x R 0.059"

(1.50mm)

3 Arrow indicates direction of

material grain.

This surface to be free of burrs

and sharp edges.

1.

Interpret dimensions and tolerances per

ANSI Y14.5M-1982

2.

Material: CRS 1010-1020, 1.00 ± 0.05 (.0394 ± .0020) thick.

3.

Finish: Zinc pre-plate per Mil.Spec. QQ-Z-325a Class 3 (0.00020) type II.

1

Mark part number, rev level,

vendor I.D., and date code

with 0.19±0.06 high

permanent contrasting

characters.

Locate where shown.

4.

Maximum burr allowance is 15% of material thickness.

5.

Tooling required to make this part to be property of Apple Computer, Inc. and

shall be permanently marked with Apple’s name and appropriate part number.

6.

All dimensions apply after finish.

Notes:

Key

2