7

107Chapter 7 Remote Drop I/O Data

Monitoring/Controlling I/O Data:

Logicmaster 90–70

Logicmaster 90–70 can be used to monitor I/O in the remote drop, either from the

PLC I/O Tables or from the Remote I/O Scanner’s internal I/O tables.

Reference Tables Display from the PLC

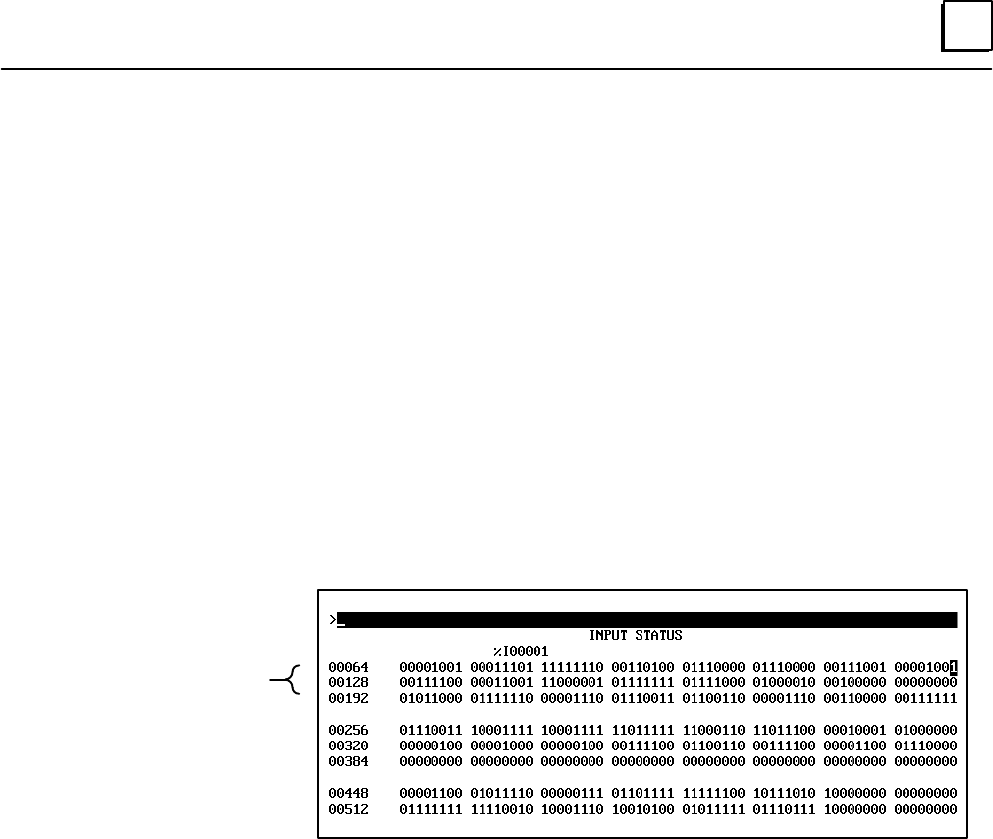

When the system is in operation and the remote drop is communicating with the PLC

via a Genius bus, the I/O in the remote drop can be monitored as part of the complete

system. The Logicmaster reference tables displays will include those portions of the

PLC’s %I, %Q, %AI, and %AQ memory being used by a Remote I/O Scanner. For

example, a remote drop uses discrete inputs %I00001 – %I00120. In the reference

tables for the PLC, these inputs are displayed along with other system inputs. When

attached to the PLC, Logicmaster 90–70 can override or toggle the I/O data and cause

a change.

%I References used by

Remote I/O Scanner

If the remote drop is on–line to the PLC, I/O cannot be toggled by a programmer

attached to the remote drop. This is because the altered data would be immediately

overwritten by the real input and output values being exchanged between the Remote

I/O Scanner and the PLC.

If the system is not yet in operation or the remote drop is not transferring I/O data

with the PLC over the Genius bus, monitoring must be done at the remote drop.

Either serial or parallel Logicmaster 90–70 can be used. In this situation, toggling

output data is possible and can be useful in checking out circuit connections.