5

81Chapter 5 Logicmaster 90 Operation with a Remote Drop

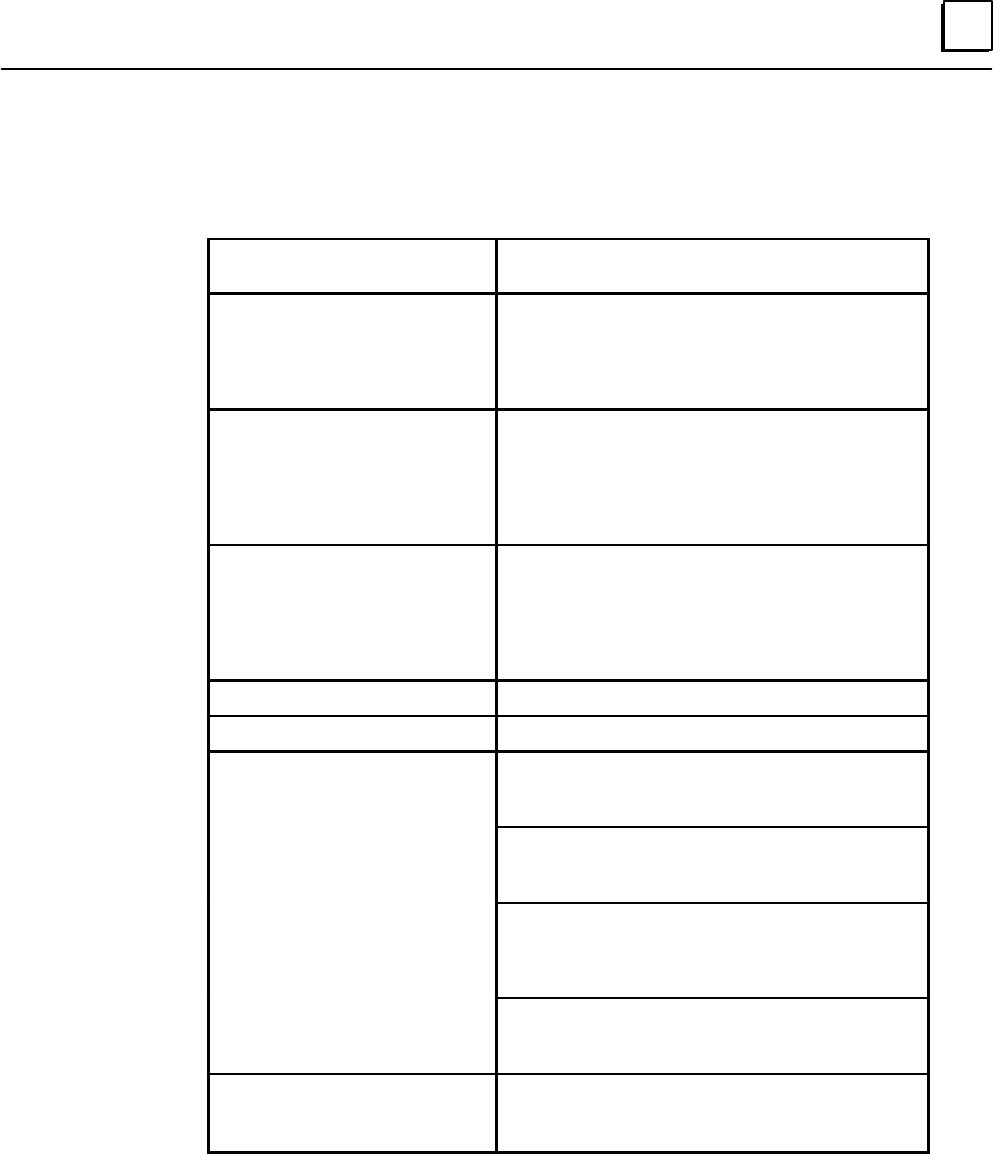

Programming Software: Differences for a Remote Drop

The features of the Logicmaster 90–70 software have the differences described below

when used with the remote drop (versus normal PLC operation).

Feature From Remote Drop LM90–70 Folder (Attached to

Remote I/O Scanner)

Program Display/Edit When communicating directly with a remote drop,

programmer is NOT EQUAL to PLC. Real–time up-

dates do not occur for the display, and online editing

changes cannot occur. PLC programs should not be

edited while the remote drop folder is selected.

Reference Tables When communicating directly with a remote drop,

%I,%AI, %Q, %AQ, %R, %S, %SA, %SB, and %SC

references can be viewed and reference states/values

can be toggled. The remote drop contains no in-

formation in %L, %M, %T, %P, and %G reference

tables.

PLC Control and Status Fault Tables The only function supported is the fault

table displays for the Remote I/O Scanner and I/O

modules in the remote drop. Faults can be cleared

from the tables. If the Remote I/O Scanner is in Stop/

Faulted mode, clearing faults from these tables may

return the module to Run mode.

Programmer Mode and Setup Normal operation.

Program Folder Functions Normal operation.

Utilities Load to Programmer: Only configurations can be

uploaded from a remote drop. The SNP ID of the

remote drop must be assigned already.

Store from Programmer: Only configurations can be

stored in the remote drop. The SNP ID of the remote

drop must be assigned already.

Verify with Programmer: Only remote drop configu-

ration can be verified against folders in Logicmaster

90–70. The SNP ID of the remote drop must be as-

signed already.

Clear Memory: Only remote drop configuration can

be cleared. The SNP ID of the remote drop must be

assigned already.

Configuration Print and

Reference View

Normal operation. Provides details of contents of

remote drop. See the Logicmaster 90–70 Software

User’s Manual for details.