7

7-21GFK-0787B Chapter 7 Programming Information

Programming for Fault and Alarm Contacts

The GMR system software can optionally utilize the Fault and Alarm contacts capability of the

Series 90-70 PLC to make fault and alarm information available to the application program logic.

Conditions that cause Fault and Alarm contacts to be set are described in the Diagnostics chapter.

Programming for Fault and Alarm contacts is explained on the following pages.

Fault and No Fault Contacts

Fault and No Fault contacts can be used to detect fault or lack of fault conditions on a

discrete (%I or %Q) or analog (%AI or %AQ) reference. They can also be programmed

with the Series 90-70’s built-in fault-locating references (see below). Unless they are used

ONLY with fault-locating references, fault memory for their use must be set up using

the CPU Configuration function of the Logicmaster 90 software.

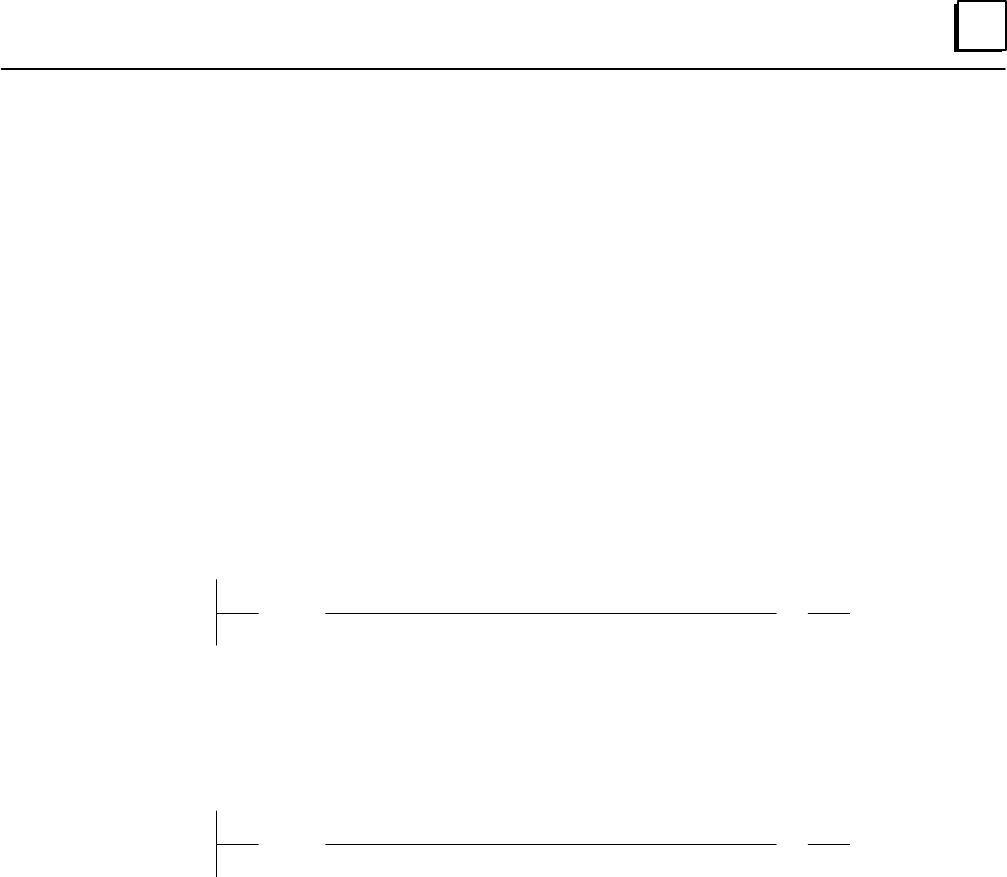

A Fault contact is programmed as shown below, using the reference address to be monitored

(here, %I0014):

%I0014

[FAULT]

%Q0056

( )

A Fault contact passes power flow if the associated reference has a fault. (Fault contacts are

also set if a block logs off the bus.)

A similar contact, called the No Fault contact passes power flow while the associated

reference has no fault.

%I0167

[NOFLT]

%Q0168

( )

Clearing Faults Associated with Fault/No Fault Contacts

When used with a %I, %Q, %AI, or %AQ reference, a fault associated with the [FAULT] contact

must be cleared to remove it from the fault table and stop the contact from passing power

flow. Fault contacts are cleared by being reset from the application program, by sending a

command to the GMR software using the %M bit for I/O Reset (%M12258). Clearing such a fault

with a Hand-held Monitor does not remove it from the fault table or stop the contact passing power flow.

Fault-Locating References

Both Fault and No-Fault contacts can be programmed with fault-locating references to

identify faults associated with the system hardware. These fault references are for

informational purposes only. The PLC does not halt execution if one of these reference

faults occurs. For a Genius device, the format of the fault-locating reference is:

M_rsbmm

Where r is the rack number 0 to 7, s is the slot number of the bus controller; b is the bus

number, and mm is the serial bus address of the affected Genius device. For example,

M_46128 represents rack 4, slot 6, bus 1, module 28. For more information about

fault-locating references, please refer to the Logicmaster 90-70 Software User’s Manual.