B

GFK-0787B B-3Appendix B Maintenance Override

Recommendations

The following recommendations are given to improve the primary safety as described

by the list:

A program in the DCS that checks regularly that no discrepancies exist between the

override command signals from the DCS and the override activated signals received

by the DCS from the PLC.

The use of the maintenance override function should be documented on the DCS

and on the programming environment if connected. The printout should include:

time stamp of begin and end.

ID of the person who is activating the maintenance override—maintenance

engineer or operator (if the information cannot be printed, it should be entered

in the work-permit).

tag name of the signal being overridden.

The communication packages different from a type-approved MODBUS should

include CRC, address check and check of the communication time frame.

Lost communications should lead to a warning to the operator and maintenance

engineer. After loss of communication a time delayed removal of the override should

occur after a warning to the operator.

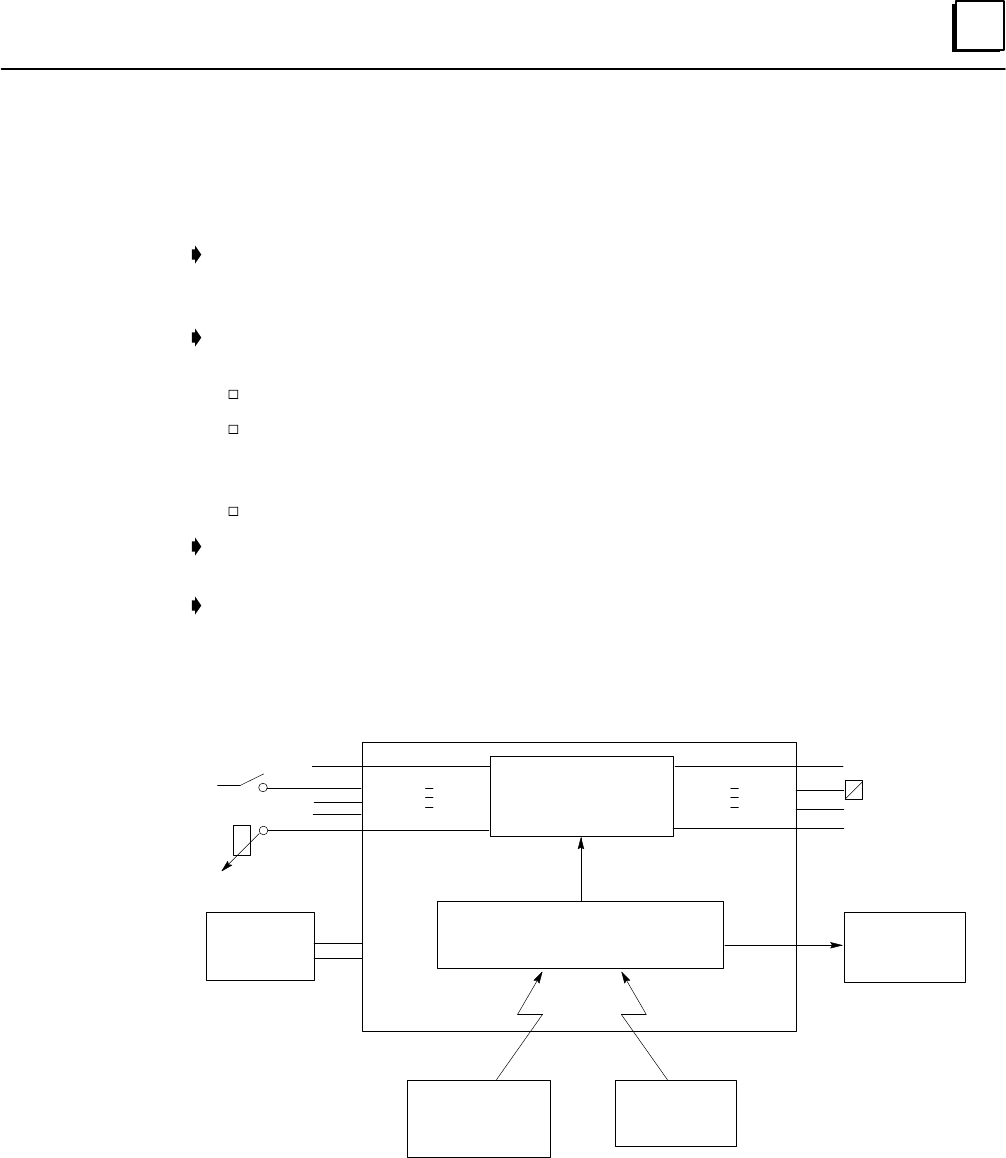

hard-wired

switch

Distributed

Control System

(DCS)

Engineering

Workstation

Maintenance Override Handling

(Application Program)

Warning to

the Operator

Safeguarding

Application Program

Sensors

PLC

serial line (e.g. Modbus)

serial line

Actuators

Version History

This version 2.2 supersedes the version 2.1 from 24. Jun 1994