84

4-way valve coil (21S4)

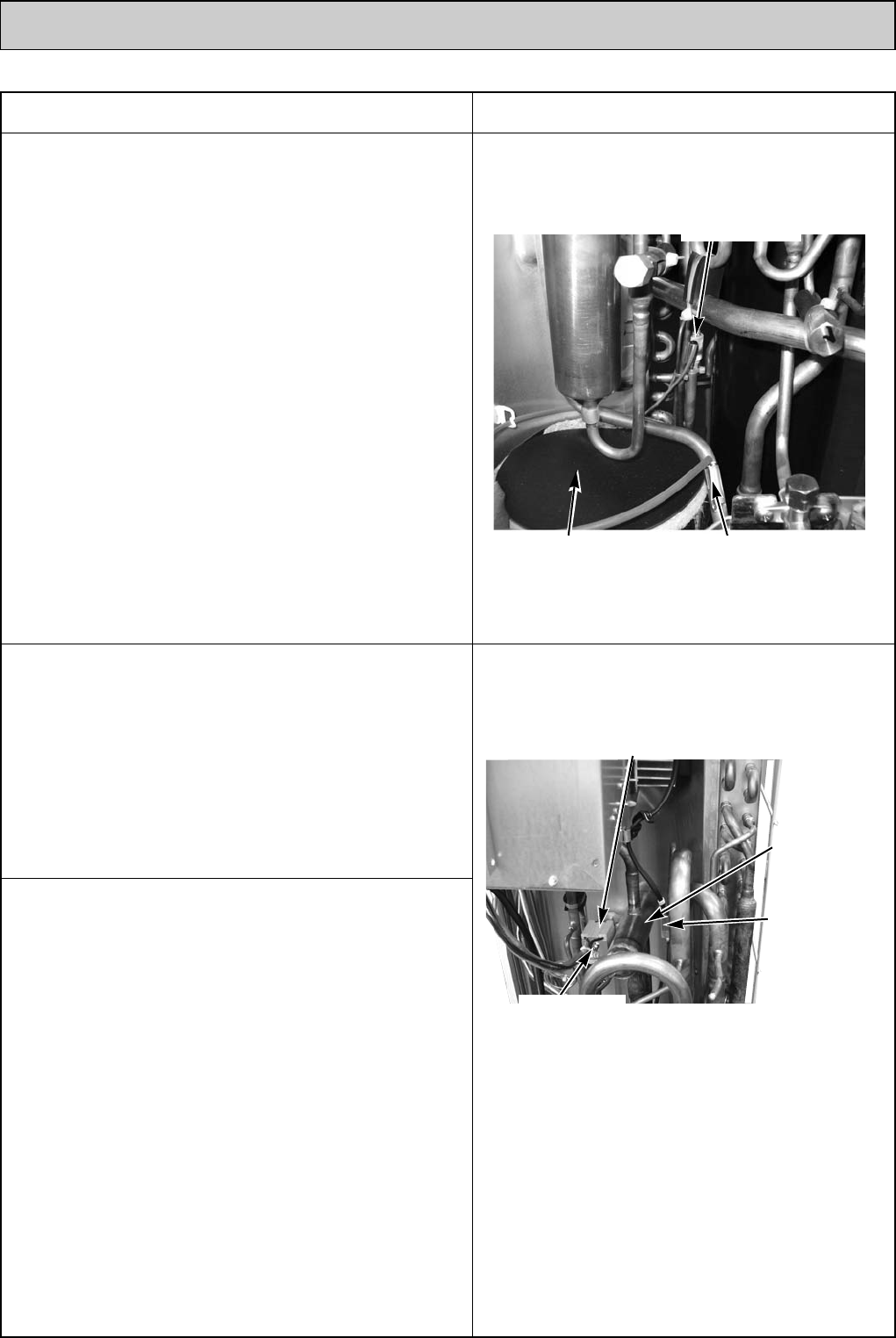

7. Removing the 4-way valve coil (21S4)

(1) Remove the service panel. (See figure 1.)

(2) Remove the top panel. (See figure 1.)

[Removing the 4-way valve coil]

(3) Remove 4-way valve coil fixing screw (M4 ✕ 6).

(4) Remove the 4-way valve coil by sliding the coil toward you.

(5) Disconnect the connector 21S4 (green) on the Multi

controller board in the electrical parts box.

Photo 8

4-way valve

Thermistor

<Low pressure

saturated temp.>

(TH6)

OPERATING PROCEDURE

PHOTOS

Photo 7

6. Removing the thermistor <Outdoor pipe> (TH3) and

thermistor <Discharge> (TH4)

(1) Remove the service panel. (See figure 1.)

(2) Disconnect the connectors, TH3 (white) and TH4 (white),

on the Multi controller board in the electrical parts box.

(3) Loosen the clamp for the lead wire in the rear of the

electrical parts box.

(4) Pull out the thermistor <Outdoor pipe> (TH3) and

thermistor <Discharge> (TH4) from the sensor holder.

Thermistor

<Discharge>

(TH4)

Thermistor

<Outdoor pipe>

(TH3)

Compressor

(MC)

4-way valve coil

fixing screw

8. Removing the 4-way valve

(1) Remove the service panel. (See figure 1.)

(2) Remove the top panel. (See figure 1.)

(3) Remove 3 valve bed fixing screws (4 ✕ 10) and 4 ball

valve and stop valve fixing screws (5 ✕ 16) and then

remove the valve bed.

(4) Remove 4 right side panel fixing screw (5 ✕ 10) in the

rear of the unit and then remove the right side panel.

(5) Remove the 4-way valve coil. (See photo 8.)

(6) Recover refrigerant.

(7) Remove the welded part of four-way valve.

Note 1: Recover refrigerant without spreading it in the air.

Note 2: The welded part can be removed easily by remov-

ing the right side panel.

Note 3: When installing the four-way valve, cover it with a

wet cloth to prevent it from heating (120°C or more),

then braze the pipes so that the inside of pipes

are not oxidized.

OC376B--3.qxp 08.1.17 1:16 PM Page 84