Service Manual

Alignment & Troubleshooting

4-4

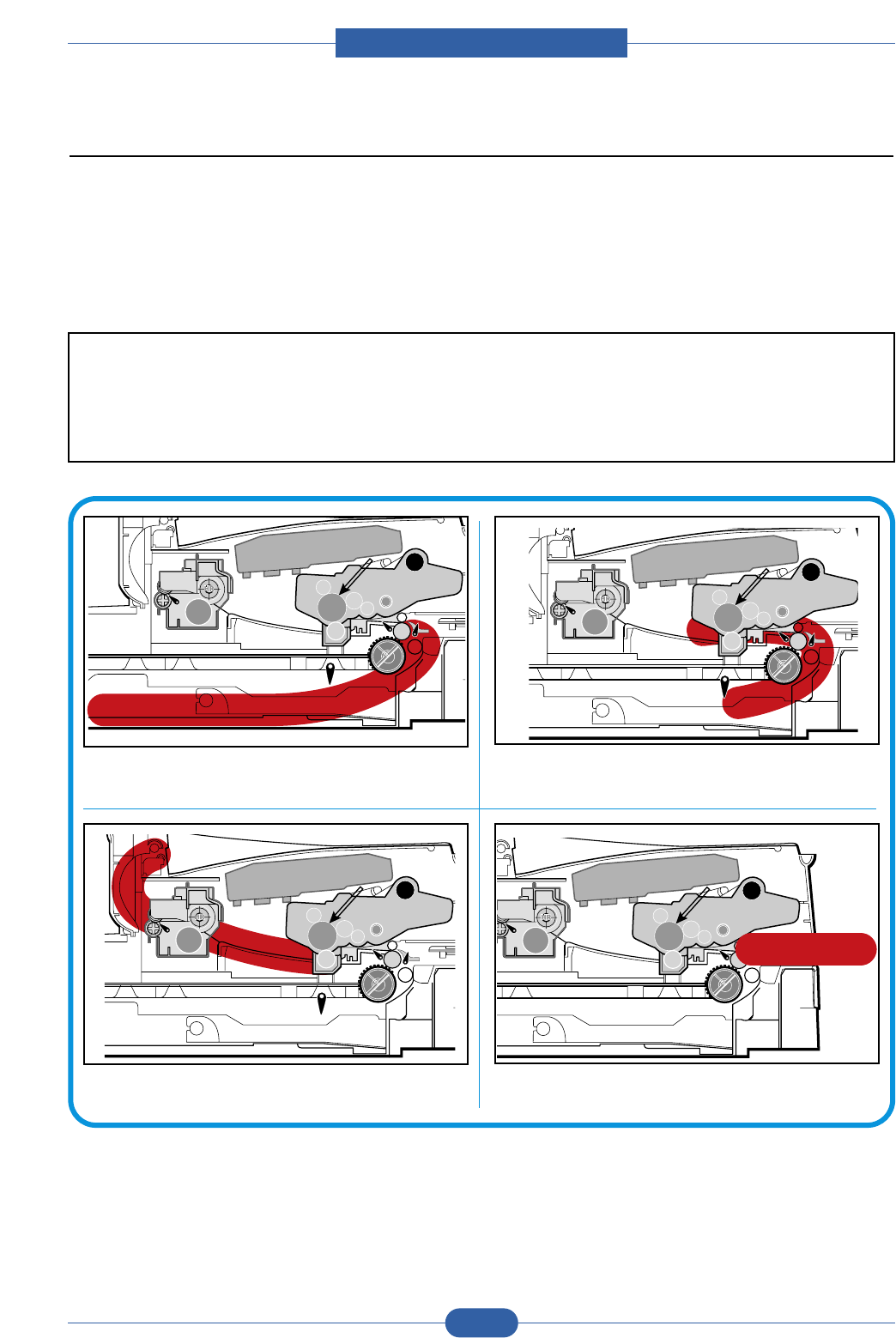

4.1.2 Clearing Paper Jams

Occasionally paper can become jammed during a print job. Some of the causes include:

• The tray is loaded improperly or overfilled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper was used that does not meet paper specifications.

• Paper that is outside of the supported size range was used.

If a paper jam occurs the On Line/Error LED on the control panel lights red. Find and remove the jammed

paper. If you don't see the paper, open the covers.

Do not use a tweezers, pincers or other metal tools when removing a jam.

This could damage the internal mechanism causing print quality problems or possibly electrical shock..

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam0

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam1

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Paper Jam2

PTL

P

I

C

K

/

R

PR

CR

DR

SR

TR FR

Empty Sensor

OPC

L S U

Fuser

Toner Cartridge

EXIT

Sensor

Feed

Sensor

MP Sensor

Bypass Jam