6 – 1

6. TROUBLESHOOTING AND REPAIR

6.1 Items to Check Before Repair

(1) Check the inspection items specified in the instruction manual.

(2) Find out as many details of the trouble as possible from the customer.

(3) Inspect in the conditions as close as possible to those at the time the trouble occurred.

(4) Proceed with the repair as follows:

Check the trouble status according to Table 6.1 for the details of the trouble. Then, locate

the trouble position according to the detailed flowchart.

(5) Carry out a thorough test after the repair to check for correct functioning.

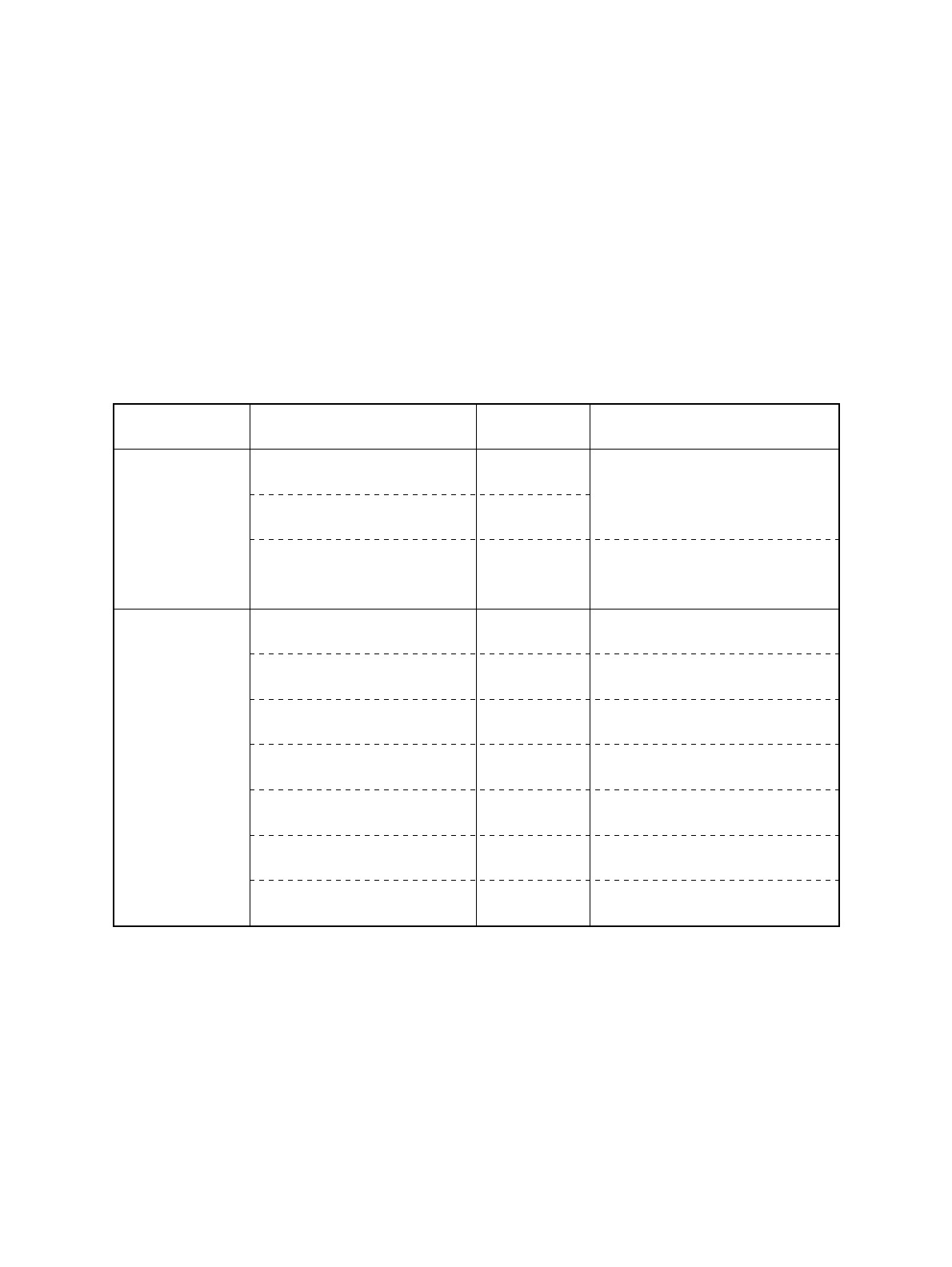

6.2 Troubleshooting Table

Table 6.1

Status Trouble Contents

Troubleshooting

Flowchart No.

Surmise of Trouble

• Power is not supplied.

• No spacing operation

1

2

Control/Power Supply Board,

Driver Board, Transformer Assy.

Space Motor, Carriage Cable,

Printhead.

• Homing does not end normally.

3

Space Motor, Carriage Cable,

Control/Power Supply Board,

Driver Board, Spacing Mechanism

Trouble upon

power on

• Paper jam while paper insertion

4

Pressure Roller Mechanism, Pull Up

Roller Cover.

• Smearing/Missing dots

5

Printhead, Driver Board, Space

Motor, Carriage Cable

• Faint or dark print

6

Printhead, Ribbon Feed Assembly,

Driver Board

• Ribbon feed trouble

7

Ribbon Feed Assembly, Space

Motor, Driver Board

• Line feed trouble

8

LF Motor, Platen Assy, LF

Mechanism, Driver Board

• Malfunction of switch on

operation panel

9

Operation Panel, Driver Board

• Data receiving failure

0

Driver Board, (I/F Board), I/F Cable,

Menu Setting

Trouble during

printing