9-27

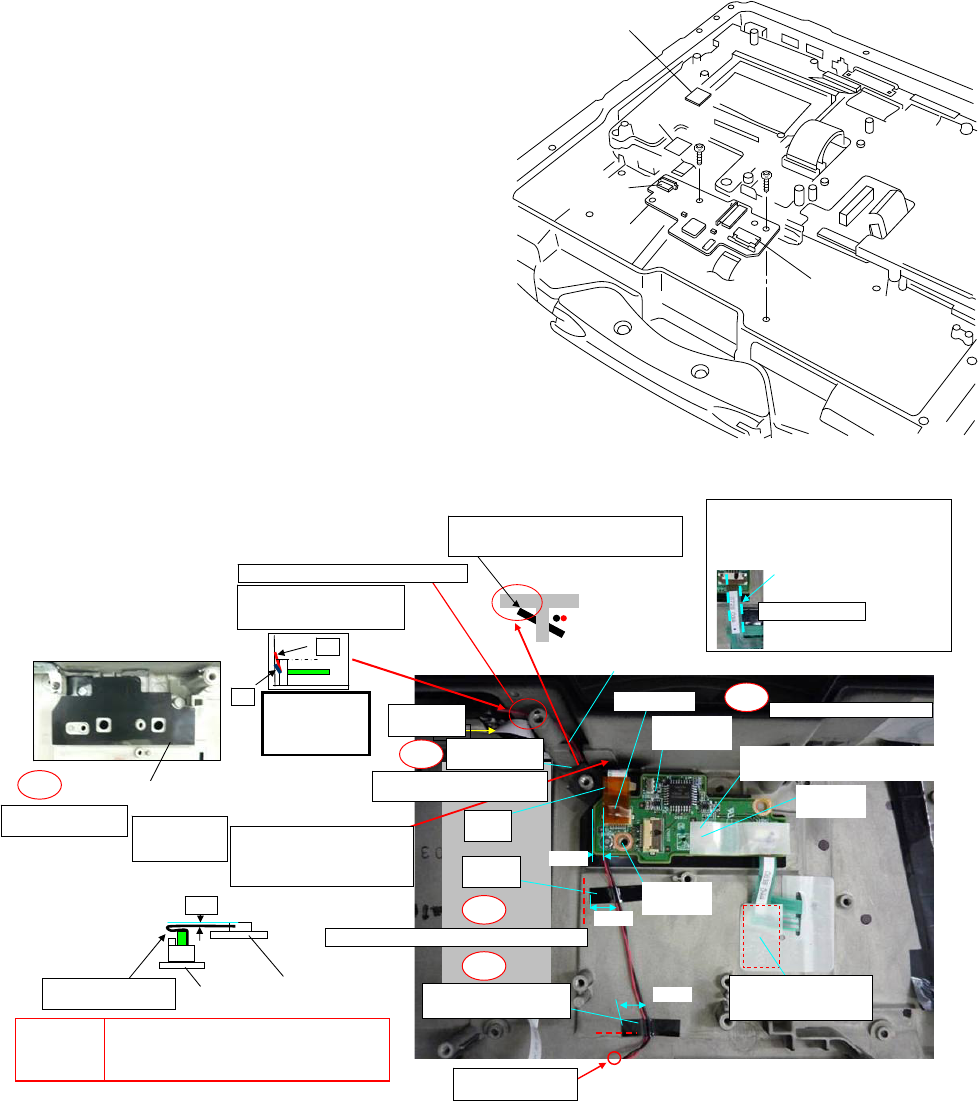

9.2.11. Setting the PAD PCB

1. Fix the PAD PCB using the 2 Screws <N29> (No1 to No2).

2. Attach the TP PCB Screw Sheet.

3. Connect the Cable to the Connector. (CN802)

4. Connect the Cable to the Connector (CN801) and attach

the Tape.

Note:

Tighten the Screws in the numbered order (No1 to No2).

Screws <N29>: DRQT26+E3FNL

Assembly of PAD PCB

Pad PCB

Connector

(CN802)

Connector

(CN801)

Tape

TP PCB Screw Sheet

<N29>

<N29>

No.1

No.2

<N29>

<N29>

No.1

No.2

7䌾11

7䌾11

0㫧2

NG

OK

2㫧1

CAUTION

S1:Insulation S2:Bitten S3:Sharp Edge

S4:Part No. Check S5:Other

1. Apply the load when attaching the attaching parts.

20 to 30N (2 to 3Kgf)/cm2

2. Reusing the attaching parts is prohibited.

Tightening torque

TAPE Attach

After inserting FFC, confirm

it is not diagonal insertion, and then

attach.(To prevent coming off)

Confirm it is not diagonal.

Example of NG

Insert into the boss at an angle to

put here close to the Cabinet side.

Avoid running over the top of boss

Ensure the wire does not

protrude from the top of

boss.

Confirm the

processed wire

View from A

direction

Insurate the Board

and Cabinet.

Avoid running

over the boss

and the rib.

When pressing not to touch

the Cabinet wall, be careful

not to bend

the FFC stiffening plate.

Process the surplus

of FFC to the back

TP INS SHEET

Attach

Process the wire

targeting the boss

Fix with Screws in order of the rear number of No.

Ex.) Fix in order of Screw-1 to Screw-2.

Remove the Release

Paper and process

the FPC

TAPE-2 Attach

Fit to the Cabinet line

Avoid catching the Cable in the Cabinet

TAPE

Attach

TAPE-1

Attach

CABLE HOLD

SHEET Set

View from

A direction

Process the SP Cable between the bosses.

Insert FFC

PWB PAD

Set

Insulate the Screw head

TP PCB Screw SHEET Attach

Match to the end of the Board

Tighten

Screw-2

Tighten

Screw-1

Torque of tightening Screw :

0.45

±

0.05

N·m(Ṑ

4.5

±

0.5

kgf·cm)

S1

S1

S2

S2

S2

Line involved prevention

to the boss of the SP cable

PWB䇭PAD

LED PWB