Unit 6: Maintenance

SATO HT200e Operator Manual PN 9001103A Page 6-5

ADJUSTMENT PROCEDURES

This printer incorporates a series of sub-assemblies that, in conjunction, comprise the total

printer assembly. Many of these sub-assemblies are designed to be adjustable to maintain

optimum performance of the printer throughout its life. This chapter of the Operator Manual

addresses the proper technique for their adjustment.

It may be necessary to refer to this chapter following component replacement. Use the relative

procedure in that chapter to replace the component, test cycle the printer, and then adjust as

necessary in accordance to the relative procedures in this chapter.

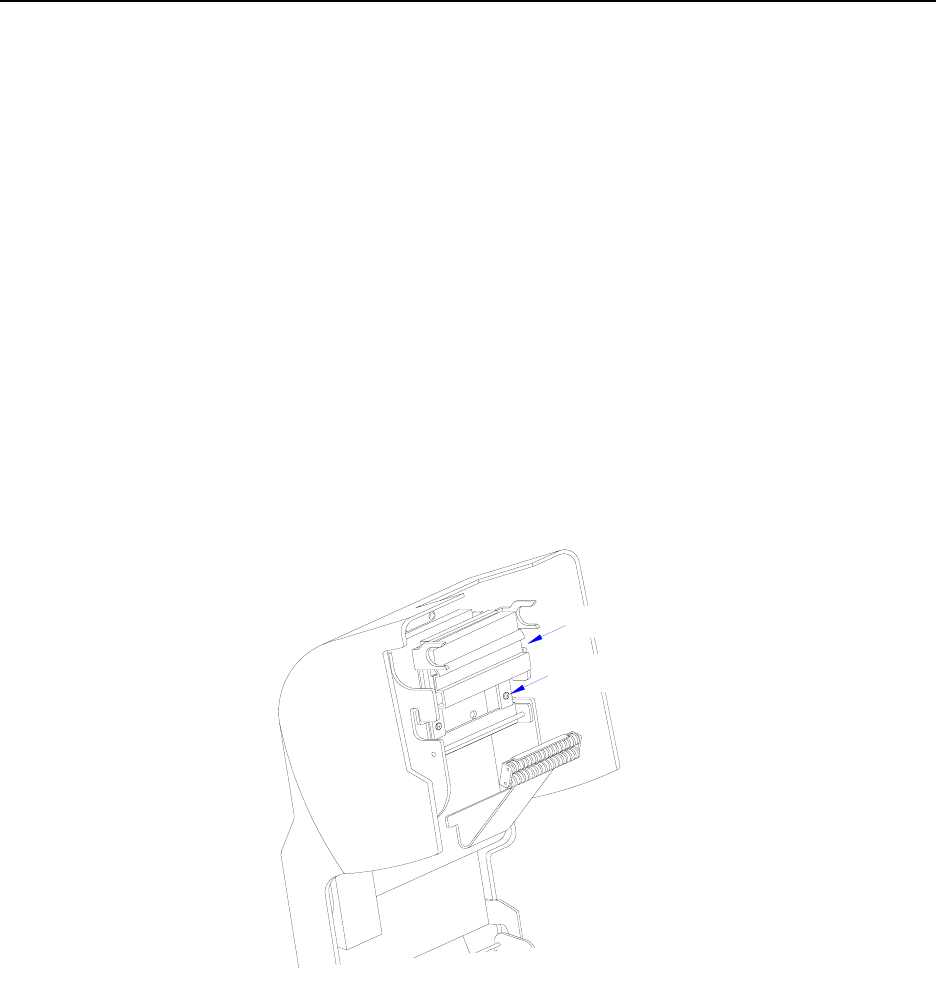

PRINT HEAD ALIGNMENT

The print head may require alignment following its replacement. Poor alignment of the print head

with the platen roller will result in print that will drift from one side toward the opposite side. To

achieve print that is perpendicular with the media, slightly loosen the two screws securing the

print head mounting bracket to the top frame assembly and alter the position of the print head

until it appears to perfectly aligned with the upper perimeter of the top frame assembly. Retighten

the two screws with the print head held in that position, then test print labels to ensure a proper

alignment.

Figure 6-2, Print Head Alignment

PRINT HEAD BALANCE ADJUSTMENT

Many printer models and makes require print head balance adjustment, this one does not. This

printer is designed to be self balancing through the utilization of dual torsion springs mounted in

the top frame assembly behind the print head. When the top housing cover is latched in the

closed position, pressure is applied to the print head against the platen roller. The two springs

enable the print head to flex ensuring full contact of the two components across their entire

length.

Screw x2

Print Head