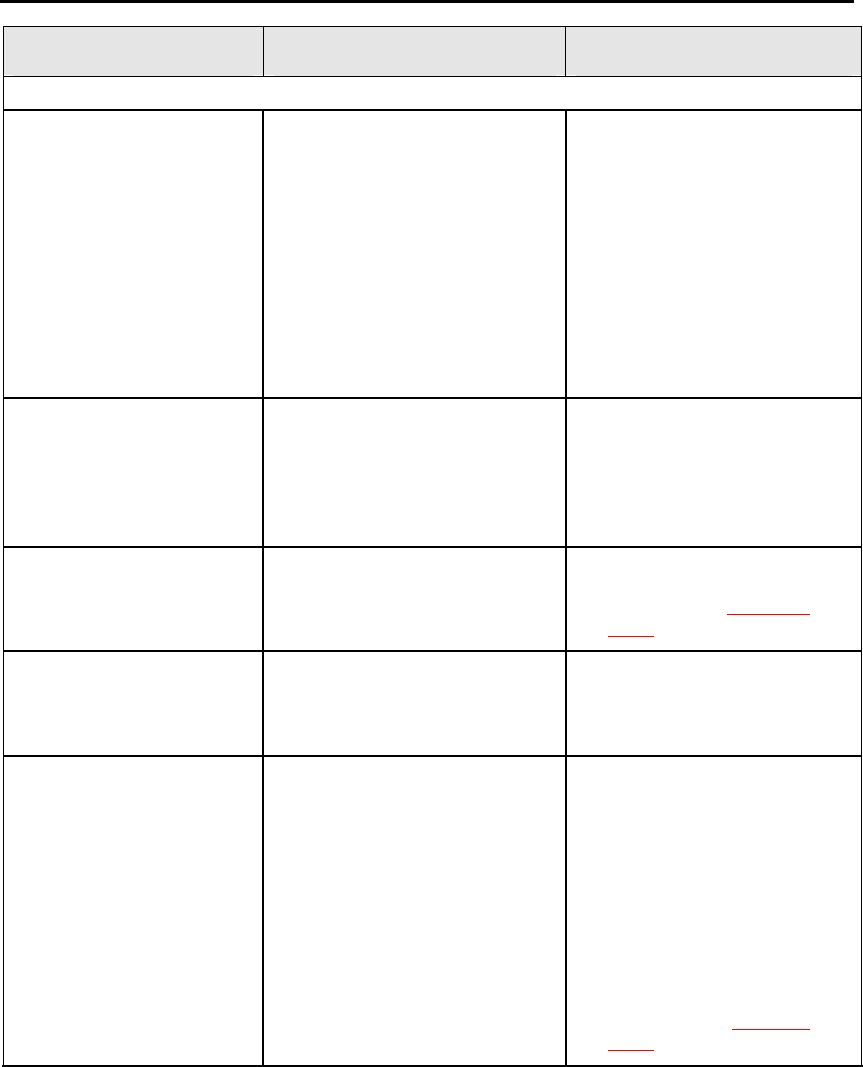

52 Appendix A: In Case of Difficulty

Common operating problems (con’t)

Symptom Potential Problem Suggested Solution

Poor image quality (con’t)

Contaminated print --

front surface

Media leading edge is curled.

The head cleaning

mechanism may not have

completely cleaned the print

heads

Determine if the media

leading edge is curled. If it is

curled, cut off the curled

area. The curls might be

caused by media wrinkle. If

you have wrinkled media,

feed the media until the

wrinkles disappear, then cut

the media.

Clean the heads using the

Head Maintenance

procedure.

Contaminated print:

back surface

A dirty or contaminated pinch

roller

A dirty or contaminated area

on the platen

Clean the pinch roller.

Clean the platen.

Dark prints

The printer might be set for

the wrong media

Ensure that 720 dpi printing

is not being performed on

360 dpi media

-

Different colors than

expected

The color displayed on the

host computer monitor and

the print colors are not

necessarily the same

Ensure both the monitor and

printer are calibrated.

Light or blank prints The RIP processor is sending

the printer invalid data.

The room temperature is out

of recommended range.

The printer may be set to the

wrong media setting

Check the RIP software to

ensure it is producing valid

data.

Adjust the room temperature

to be in the range between

60°F (15°C) to 85°F (30°C) ;

preferably 72°F (23°C), and

let the equipment stabilize at

the new room temperature.

Ensure that 360 dpi printing

is not being performed on

720 dpi media

-