Page 15

crystal where it is aligned as the image requires and reflected back out. If the

SXRD pixel has rotated the light, it then is not aligned with the post-PBS

polarization and is allowed to pass. If the incoming light has not been rotated,

then it is blocked by the post-PBS and reflected back into the source light path.

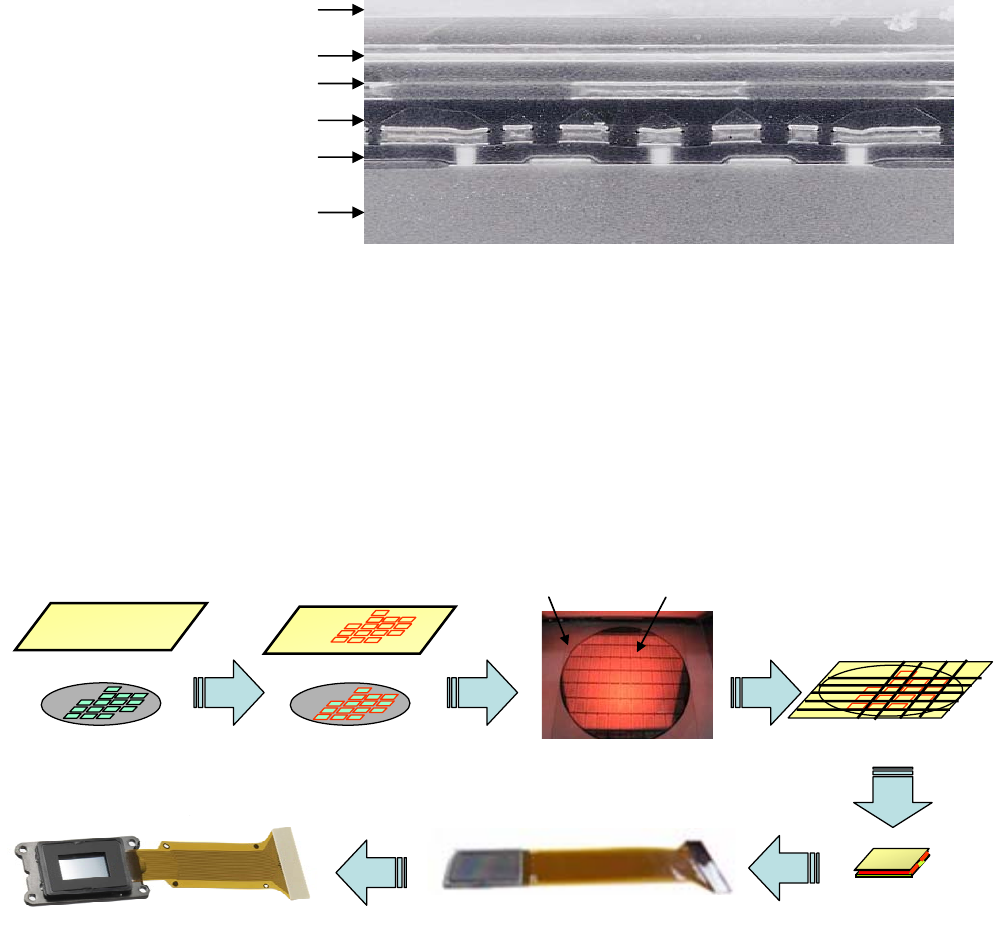

Photomicrograph of the SXRD panel silicon backplane in cross section.

SXRD panel production

Unlike conventional LCoS panels, which are notoriously difficult to

manufacture, the SXRD panel uses a production process that Sony has

perfected in the company’s own, dedicated manufacturing facilities. This has

enabled Sony to bring SXRD technology smoothly into production, while taking

advantage of its many benefits.

Inorganic Alignment

Layer

IMITO glass

Si backplane

Print Sealing &

Common Electrode

Singlation

LC fill & Seal

Electrode Attachment

Packaging

IMITO glass

Si backplane

Assembly

Sony assembles the IMITO glass and silicon backplane prior to cutting

the wafer into individual panels (singlation). In this way, Sony achieves

three key features: a narrow cell gap, dust-free process and no LC gap

spacers in the image area.

Silicon Substrate

Polysilicon Process

1

st

Aluminum Process

2

nd

Aluminum Process

4

th

Aluminum Process

3

rd

Aluminum Process