GRN4-610 Chapter 2: Functional Description 16 of 73

Control

The pusher feeds the rotor with as much material as it is able to process. Upon reaching

70-90 % of rated current, the feeding of the pusher will be stopped and automatically

started again after the power consumption has fallen by 20 % in comparison with rated

current. If the high current is applied for longer than 0.7 - 1.5 sec., the main drive motor

switches off and runs back after about 3 sec. standstill time. The pusher plate also runs

back whilst the rotor runs back. The drive motor then stops for another 3 sec. before

starting again. The position of the pusher is controlled by an optical distance sensor. The

in feed is controlled according to load. Duration of pauses and return as well as the

current settings can be adjusted. Any alterations, however, should only be carried out

after consulting the manufacturer.

Grinding Material In-feed

The grinding material can be fed into the shredder using the following methods:

• Manual in-feed of the grinding material directly into the feeding trough.

• Manual in-feed of the grinding material with the help of an additional in-feed

device (i.e. hydraulic feeding unit).

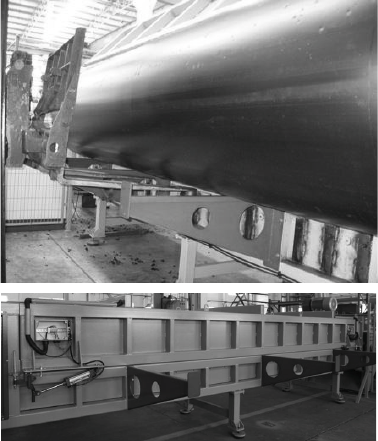

In-feed Hopper

The grinding material in-feed ensues via a feeding trough. The pipe can be placed easily

in the feeding trough by a forklift.

Illustration:

Feeding trough

The feeding trough has a hydraulically operated cover, which is

closed after it is filled with material.

A hydraulic ram system is than pushing the material towards the rotor.