WARNING:MAXPressure–7psi.Neverpressurizetankwithballvalveopen.

Ifusedoildoesnotevacuat etankuponpressurization,checkthatballvalveisfullyclosed(handle

in horiz on tal position). If this does not correct the problem, remove the unit from service and

contactanauthorizedservicecenterfor

repair.

If the pop‐off valve relieves ANY air pressure from the tank, remove the unit from ser vice and

contactanauthorizedservicecenterforrepair.

WARNING:

ALWAYSremoveoildrainandanytools,jacks,etc.andfromundervehiclebeforeloweringlift.

ASSEMBLY

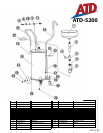

1. Removetankfrombox.Slide1/2 ” diametersteelaxle(#25)throughaxlehousingonbottomof

tank(#15). Place wheel (#21)onaxle (#25),securing withwasherandretaining ring (#22 &

#23).Repeatforotherwheel.

2. Remove wood spacers from caster s brackets. Slide stud of cas ter (#20)

through bracket,

securingwithwasherandnut(#18).Repeatforothercaster.

3. PlaceTFEpipesealantonthreadof3/4 ” NPTbarbedfitting(#1 7)andscrewintolowerfittingon

sideoftank(#15).Slideloopclamp(#16)overendofhose(#14).Thenpushendofhose

(#14)

overbarbedfitting(#17).Slidetheloopclamp(#16)downoverhose(#14)andbarbedfitting

(#17)andtightenforuse.

4. Placeloopclamp(#13)aroundtubingandfastentotank(#15).Continuallykeepingtensionon

hosetokeepasstraightaspossible.

5. PlaceTFEpipesealant

on1‐1/2” NPTnipple(#5)ontopdomeoftank.Screw1‐1/2” ballvalve

(#7)in totank(#15).Screwclampingknob(#4)into 4”pipenipple(#3).(NOTE:Onlyoneofthe

fourholesin4”nippleisthreade d.Theother3holesarenon‐threadedpressurereliefports.)

6. PlaceTFEpipesealantonfunnelassembly(#1).Thenputdraintube(#2)andfunnelassembly

(#1)intotank(#15)throughthe4”nipple(#3)andballvalve(#7)assembly.Allfittingsshould

betightsoastopreventanyleaking.