— 11 —

P75

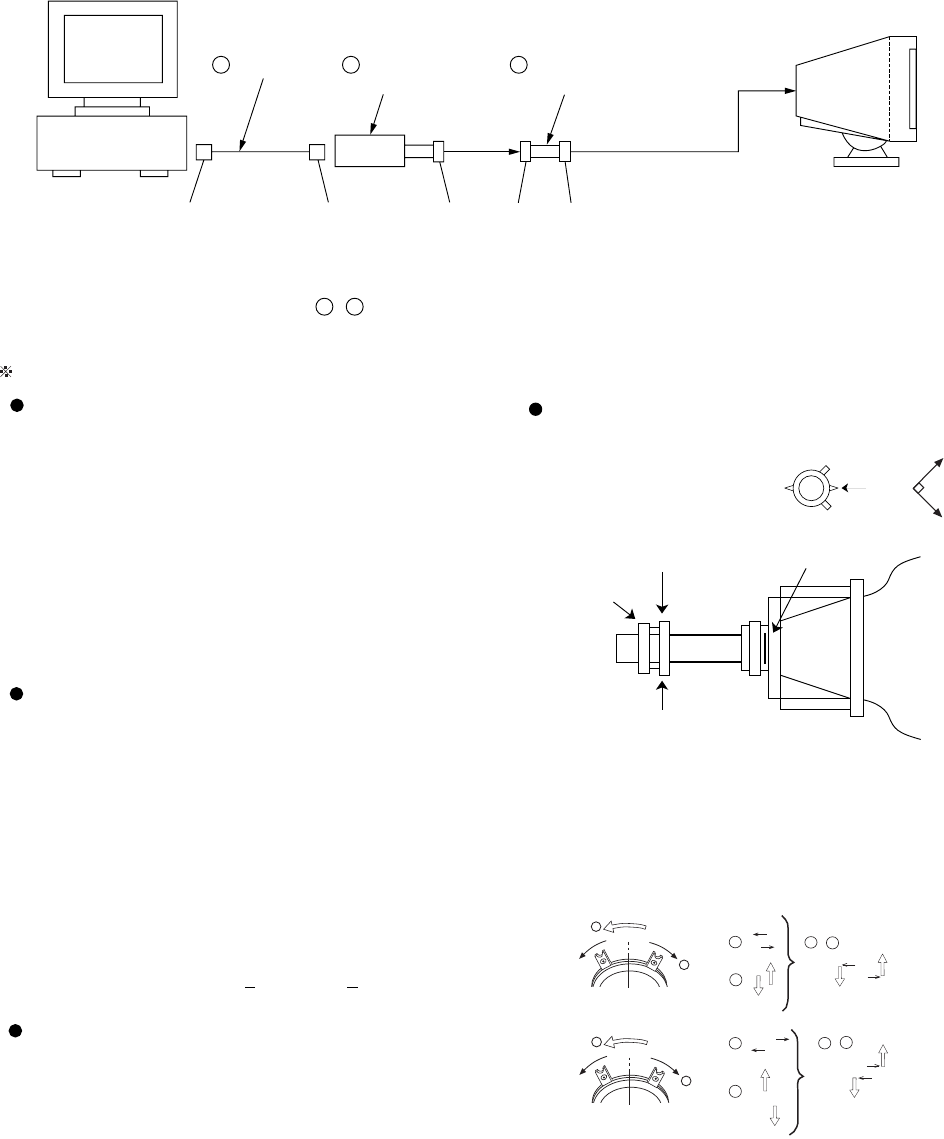

Convergence Fine Adjustment

Set DY four-pole magnet to mechanical center

before adjustment.

This should be prime mode.

1. Receive R.B. cross-hatch.

2 Adjust H.STAT and V.STAT at four-pole magnet.

4 Pole Magnet

SECTION 4

ADJUSTMENTS

Landing Rough Adjustment

1. Enter the full white signal.

2. Adjust the contrast to the maximum.

3. Input full green signal.

4. Moving the DY backward, and adjust coarsely the purity

magnet sothat a green raster positions in the center of

screen.

5. Moving the DY forward, adjust so that an entire screen

becomes pure green.

6. Adjust the tilt of DY, and tighten lightly with a clamp.

• Landing Fine Adjustment

1. Place the set in the Helmholtz coil.

2. Enter a green signal only.

3. Degauss the entire screen with hand-degausser. Then auto-

degauss it.

4. Attach a wobbling coil to the specified position of CRT

neck.

5. Attach a landing adjuster sensor on the CRT.

6. Using a landing checker, adjust the DY position, purity,

tilt of DY.

7. Clamp the DY screw.

Clamping torque: 22

+ 2 kgcm (2.2+ 0.2 N.m)

• Convergence Rough Adjustment

1. All digital convergence data should be zero by MCP.

2. Enter the white crosshatch signal.

3. Adjust roughly the horizontal and vertical

convergence at four-pole magnet.

4. Adjust roughly HMC and VMC at six-pole

magnet.

*The parts above ( ~ ) are necessary for DAS adjustment.

IBM AT Computer

as a Jig

1-690-391-21

1

A-1500-819-A

Interface Unit

2

3

D-sub

(9 Pin [female])

mini Din

(8Pin)

4 Pin

3-702-691-01

Connector Attachment

3

To BUS CONNECTOR

4 Pin 4 Pin

1

2

1

R

B

R

B

R

B

R

B

1

2

R

B

R

B

2

1

2

1

+

2

1

+

2

1

Set the

finger

Mechanical

Center

NECK Assy

6-pole Mg

P.S Mg

XBV

DY CRT

4-pole Mg

Connect the communication cable of the connector located on the D board on the monitor. Run the service software and

then follow the instructions.

Allow a 30 minute warm-up period prior to making the following adjustments:

P.S Mg