CR NO.

HW LW

Attribute

Factory

setting

Latched

Mode Function explanation

V1.00 version.

#35~#49 Reserved

#50 R K51

°

1,3 The index of F0 record value (record the number from CR51~130)

#51~#130 R K0

°

1,3 F0 record value (each value occupy 2 group CR)

#131 R K132

°

1,3 The index of F1 record value (record the number from CR132~211)

#132~#211 R K0

°

1,3 F1 record value (each value occupy 2 group CR)

#222~#255 Reserved

The usage of CR varies based on operation mode. Please follow the table above to read or write CR.

In column Attribute, ‘*” means writing is allowed when frequency measurement card is not working.

When the writing value is out of available range, the value of upper/lower bound shall prevail to write once the

value is out of upper/lower bound.

The CR28 and CR29 are the time-out setting for F0 and F1. When setting them to a non-zero value in mode 1,

it will monitor the signal input from F0 or F1 and start a time-out counting. If no signal detected in F0 and F1 with

the time-out counter reaching the setting, it will clear the CR10~CR11 or CR12~CR13 and inform the PLC by

I180 interrupt. Moreover, when CR28 and CR29 are set to zero, the time-out counter will not work anymore.

CR50~CR211 will record the value according to the operation mode. Explanation as follows:

Mode 1 Mode 2 Mode 3

CR51~CR130

To record F0 pulse interval (CR10,

CR11)

N/A N/A

CR132~CR211

To record F1 pulse interval (CR12,

CR13)

N/A

To record F1 pulse interval

(CR25, CR26

The index number of each record is plus 2 for CR50 and CR131 after both registers record on next. Once the

index number reaches to the maximum, it will back to the 1

st

index number.

It takes about 125us for instruction FROM/TO to read or write a CR of the frequency measurement card. One

more read/write item of CR, 30us more for register.

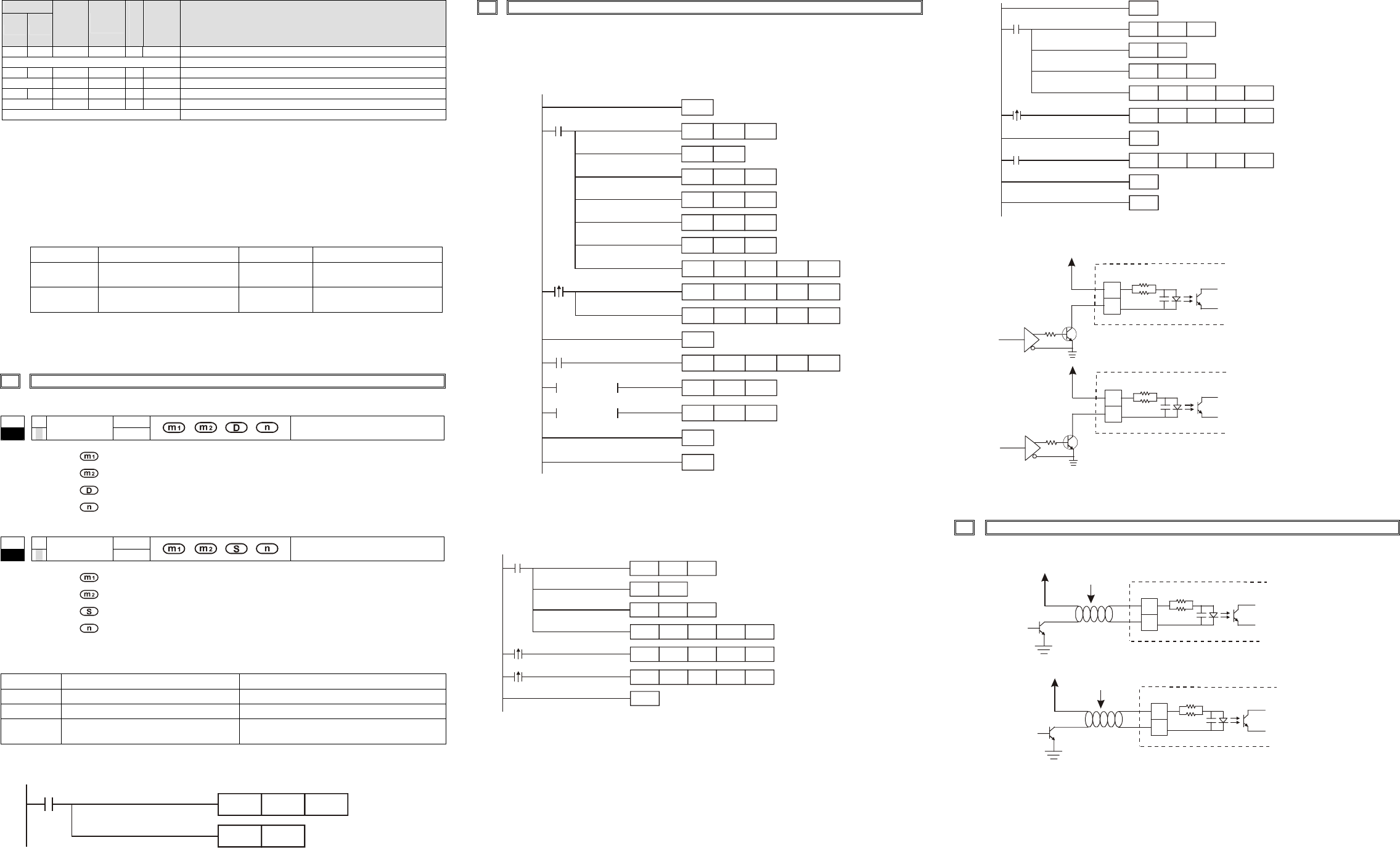

5 INSTRUCTION EXPLANATION

5.1 Instruction Explanation for Frequency Measurement Card

API

78 D

FROM

P

Read Special Module CR Data

Instruction

Explanation

: Number of special module (m1=0~7). Number of frequency measurement card, m1=200.

: Number of CR of special module that will be read.

: Location to save reading data.

: Data number of reading one time.

API

79 D

TO

P

Special Module CR Data Write In

Instruction

Explanation

: Number of special module (m1=0~7). Number of frequency measurement card, m1=200.

: Number of CR of special module that will be read.

: Location to save writing data.

: Data number of reading one time

5.2 Explanation of special D, M and Interrupt:

Device Explanation Range

D1034 Mode setting of frequency measurement card D1034 = K1~K3 (Mode 1~Mode 3)

M1019 Flag of mode setting

I180

Frequency measurement card trigger

interrupt

After PLC run at the first scan time, PLC will detect flag M1019 is ON or OFF. If M1019 is ON, PLC will modify

the frequency measurement card’s operation mode based on D1034 setting. Program example as follow is

operation mode 1:

M1002

MOV

K1 D1034

SET M1019

PLC can use M1019 (flag of operation mode setting for frequency measurement card) and D1034 (flag of

operation mode setting for frequency measurement card) to set operation mode 1 (measurement of pulse

interval) and operation mode 2 (measurement of pulse number) to support Interrupt function I180.

6 APPLICATION EXAMPLE

6.1 Pulse Interval Length Measurement

Following the program example of setting operation mode 1 (D1034, M1019) for frequency measurement card.

For F0 and F1, set the time unit of sampling rate is 100ns (D7, D8) and the sampling record number as 20 (D3,

D4). Moreover, I180 will be triggered when F0 or F1 detects a rising or falling edge. PLC can read CR9 via

instruction FROM to decide which channel to detect the signal.

END

IRET

DMOV D12 D300

D10

FROM K200 K9 K11

DMOV

D9

D300

M1000

M1002

D1034

K200

FROM

K200

FROM K200

M1013

I 180

EI

MOV K1

SET M1019

MOV

MOV

MOV

MOV

TO

K20

K20

K2

K2

D3

D4

D7

D8

K3 D3 K6

K50 D50

K41

K131 D131 K41

FEND

& D9 K1

& D9 K2

6.2 High-speed Counter

The setting for the following program example:

1. Operation mode: Mode 1.

2. Counting method: Pulse/Direction.

3. Set M0=ON to start counting.

END

M1002

D1034

K200

FROM K200

M1013

MOV

SET M1019

MOV

TO

K2

K200

M0

TO K24 K1 K1

K20 D20 K3

K1K22 D22

K0 D22

6.3 Pulse Number Capture

The following program example is Mode 3 for frequency measurement card. Whenever frequency

measurement card detects the rising-edge in F1, it will trigger the Interrupt I180 of PLC. When PLC execute

Interrupt I180, it will read the content of CR25, 26 of frequency measurement card via instruction FROM.

M1002

D1034

K200

FROM K200

M1013

MOV

SET M1019

MOV

TO

K200

K20

K1

K3

D4

D4K4

K131

D131

K40

FEND

FROM

END

IRET

K25 D25

K2

M1000

I 180

EI

6.4 Differential Input Interface (please refer to the following wiring method)

A+

A-

+24VDC

4.7K

F0

4.7K

470

Differential

output

NPN Tansistor

ON MMBT4401LT1G

B+

B-

+24VDC

4.7K

F1

4.7K

470

Differential

output

NPN Transistor

ON MMBT4401LT1G

Suggestion: if it is necessary to measure the input signal of frequency measurement card, please connect one

clip of the oscillograph probe to either terminal A- or B- and the other clip of the oscillograph probe to the

ground .

7 INSTALLATION AND MAINTENANCE

Wiring Method for Frequency Measurement Card

A+

A-

4.7K

F0

4.7K

Isolating cable

+24VDC

Open collector

output

B+

B-

4.7K

F14.7K

+24VDC

Isolating cable

Open collector

output

There is a SDSP1 indication LED in the front end of the DVP-F2FR frequency measurement card. When power

on the PLC MPU, the LED will light up (green). If the LED doesn’t light up with power on, it means that there is

error with the card. Please power off the PLC and re-install the card again.

Before power on the system, please check A/B phase loop and make sure they connect to the input terminal

with correct electrical level.