3 Function/Electrical Specification

Model

Item

DVPPS01 DVPPS02

Power Input

100~240 VAC (-15%~+10%), 50 / 60 Hz 100~240 VAC (-15%~+10%), 50 / 60 Hz

Output Power

24VDC (±3%), output current: 1A max. 24VDC (±3%), output current: 2A max.

Ripple & Noise

Under 100mV

p-p

Typical at full load Under 240mV

p-p

Typical at full load

Efficiency

78%~87% Typical at full load

Over Load / Short Circuit Protection

Auto Recovery

Grounding

The diameter of grounding wire cannot be smaller than the wire diameter of terminals L and N

(All PLC units should be grounded directly to the ground pole).

Operation/Storage Environment

Operation: 0℃~55℃ (Temperature), 50~95% (Humidity), Pollution degree 2;

Storage: -25

℃

~70

℃

(Temperature), 5~95% (Humidity)

Agency Approvals

Underwriters Laboratories, Inc.: UL508 Listed (Industrial Control Equipment)

European Community EMC Directive 89/336/EEC and Low Voltage Directive 73/23/EEC

Weight (g)

158 250

4 Installation and Wiring

4.1 Mounting Arrangements and Wiring

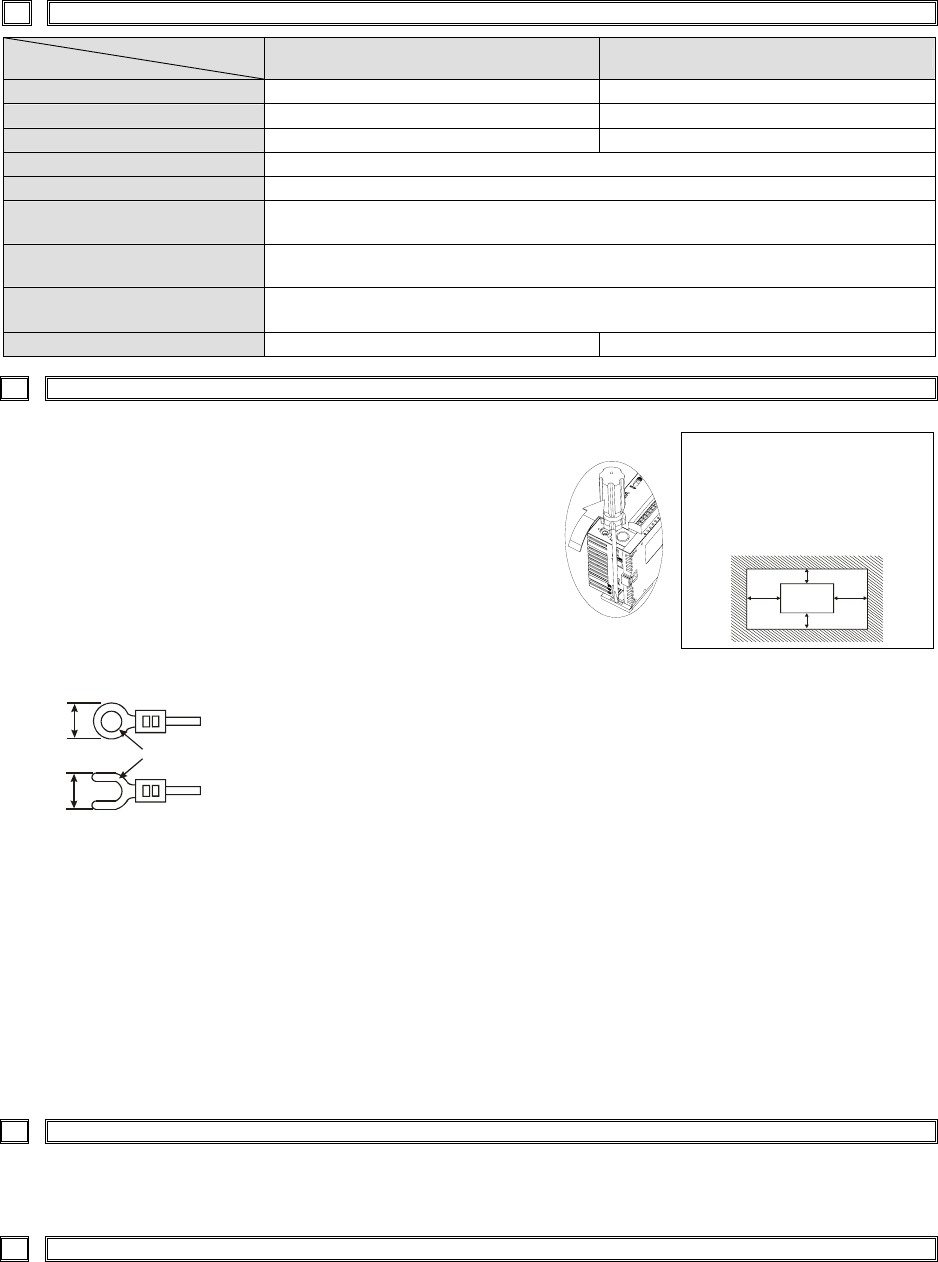

■ DIN Rail Installation

The DVPPS can be secured to a cabinet by using the DIN rail that is 35mm

high with a depth of 7.5mm. When mounting the DVPPS on the DIN rail, be

sure to use the end bracket to stop any side-to-side motion of the DVPPS,

thus to reduce the chance of the wires being pulled loose. On the bottom of

the DVPPS is a small retaining clip. To secure the DVPPS to the DIN rail,

place it onto the rail and gently push up on the clip. To remove it, pull down

on the retaining clip and gently pull the DVPPS away from the DIN rail.

Please see the figure on the right:

For heat dissipation. Make sure to

provide a minimum clearance of

50mm between the unit and all

sides of the cabinet. (as shown

below)

DVP MPU

> 50mm> 50mm

> 50mm

> 50mm

■ Direct mounting: Tighten M4 screws into direct mount hole.

■ Wiring

To suit M3.5 screw terminals

Below 6.2

Below 6.2

Notes:

1. Please use O-type or Y-type terminals for I/O wiring terminals. The specification for the terminals is

as shown on the left. Tighten PLC terminal screws to a torque of 5~8 kg-cm (4.3~6.9 in-lbs).

2. Please avoid tiny metal material enter DVPPS01/PS02 when screwing and wiring. After finishing

wire, remove the affix that pasted on the heat sink for heat dissipation.

3. Use Copper Conductors Only, 60℃.

4.2 Wiring Notes

■ Environment

1.

DO NOT

store the DVPPS01/PS02 in a dusty, smoky, or corrosive atmosphere.

2.

DO NOT

store the DVPPS01/PS02 in an environment with high temperature or high humidity.

3. DO NOT install PLC on a shelf or on an unstable surface.

■ Power Input Wiring

Power input of DVPPS01/PS02 is AC input; following items should be noticed:

1. Connect the AC input (100VAC ~ 240VAC) to terminals L and N. Any AC110V or AC220V connected to the +24V terminal will

permanently damage the DVPPS01/PS02.

2. Please use wires of 1.6mm and above for the grounding.

3. If the power-cut time is less than 10ms, the DVPPS01/PS02 still operates unaffectedly. If the power-cut time is too long, the

DVPPS01/PS02 will stop operating and all the outputs will be Off.

5 Trial Run

☼ Power indicator, Running and Test

The “POWER” LED at the front of DVPPS01/PS02 will be lit (in green) if the power is on. If the indicator is not ON, it indicates that the

power supply is not enough or short circuit. Please check your power wiring.

6 Troubleshooting

Judge the errors by the indicators on the front panel. When errors occurred on DVPPS01/PS02, please check:

☼ 「POWER」LED

The “POWER” LED at the front of the MPU will be lit (in green) if the power is on. If the indicator is not on when the MPU is powered up,

please check if power supply is normal. If the indicator is not on when the MPU is powered up and with the input power being normal, it is

an indication that the PLC is malfunction. Please have this machine replaced or have it repaired at a dealer near you.