110, 230, and 450 Series Steering Control Units

4

Cleanliness is extremely important when repairing a steering

control unit. Work in a clean area. Before disconnecting lines,

clean port area of unit thoroughly. Use a wire brush to remove

foreign material and debris from around exterior joints of the unit.

Although not all drawings show the unit in a vise, we recommend that

you keep the unit in a vise during disassembly. Follow the clamping

procedures explained throughout the manual.

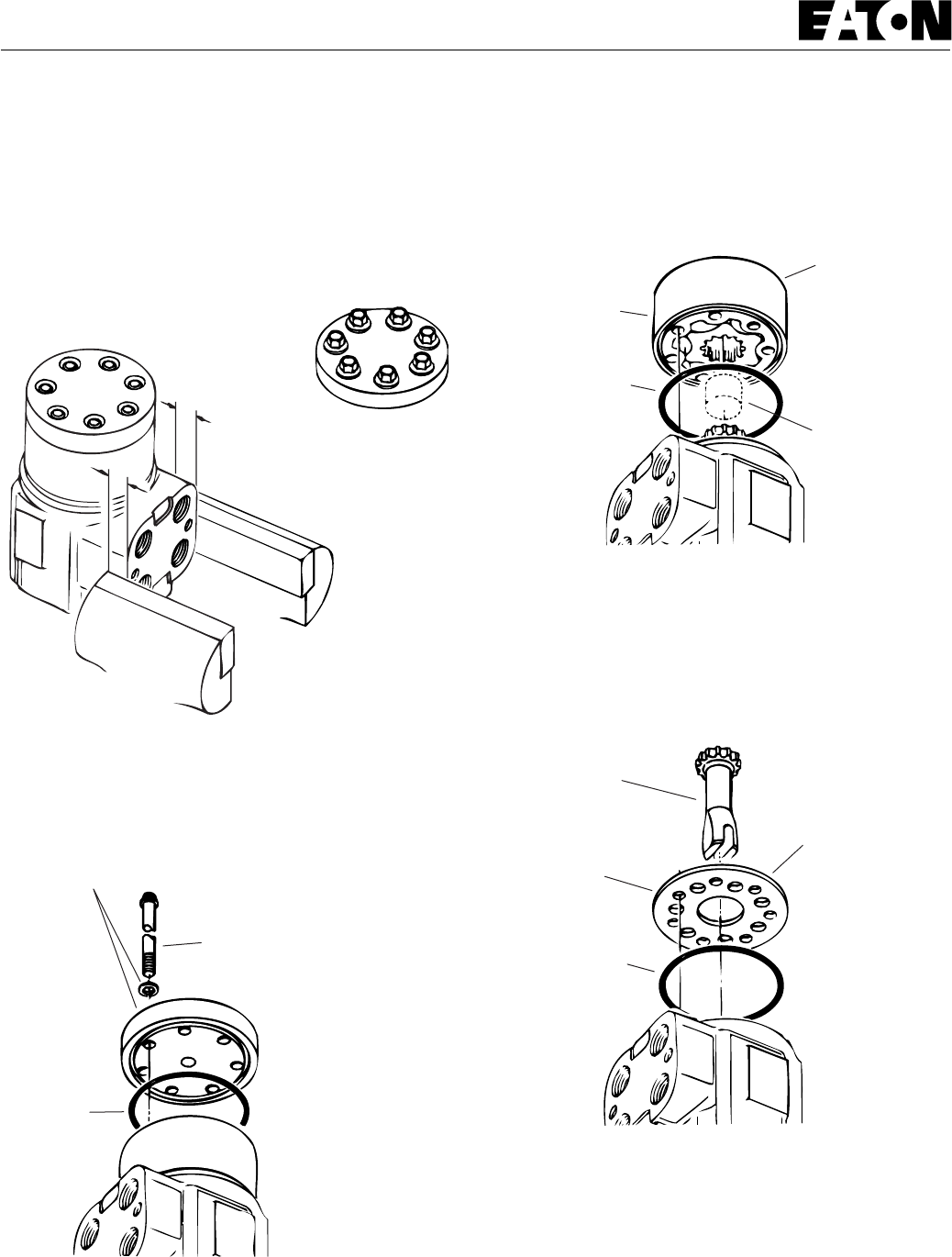

1 Clamp unit in vise, meter end up. Clamp lightly on edges of port

face sides (see figure 1). Use protective material on vise jaws.

Housing distortion could result if jaws are overtightened.

2 Remove 5/6 in. cap screws and sealing washers, if used.

3 Remove end cap.

4 Remove seal.

5 Remove meter. Be careful not to drop star.

6 Remove seal.

7 Remove drive spacer. Spacer is not used on some models. Refer

to Parts Information No. 6-321 to determine if spacer is used on your

particular model.

8 Remove drive.

9 Remove spacer plate.

10 Remove seal from housing.

11 Remove housing from vise.

25 mm

[1 inch]

Max.

Gerotor (Meter) End

-002 Steering

Control Unit

with 6 Point

(E10) Drive Screws

or Current Hex

Head Screws

Cap Screw

Seal

Seal washers are not used with 6 point (E10) drive

screws or current hex head screws and -002 end cap

(-002 end cap does NOT have the o-ring groove)

Meter (Gerotor)

Seal

Spacer

Seal Groove

this Side

-002 Unit.

See Note

Inside Front

Cover (Page 2)

Drive

Seal

O-ring Groove

this Side -002

Unit — Old

Spacer Plate

has No O-ring

Groove

Spacer Plate

Disassembly

Figure 1

Figure 2

Figure 3

Figure 4