110, 230, and 450 Series Steering Control Units

5

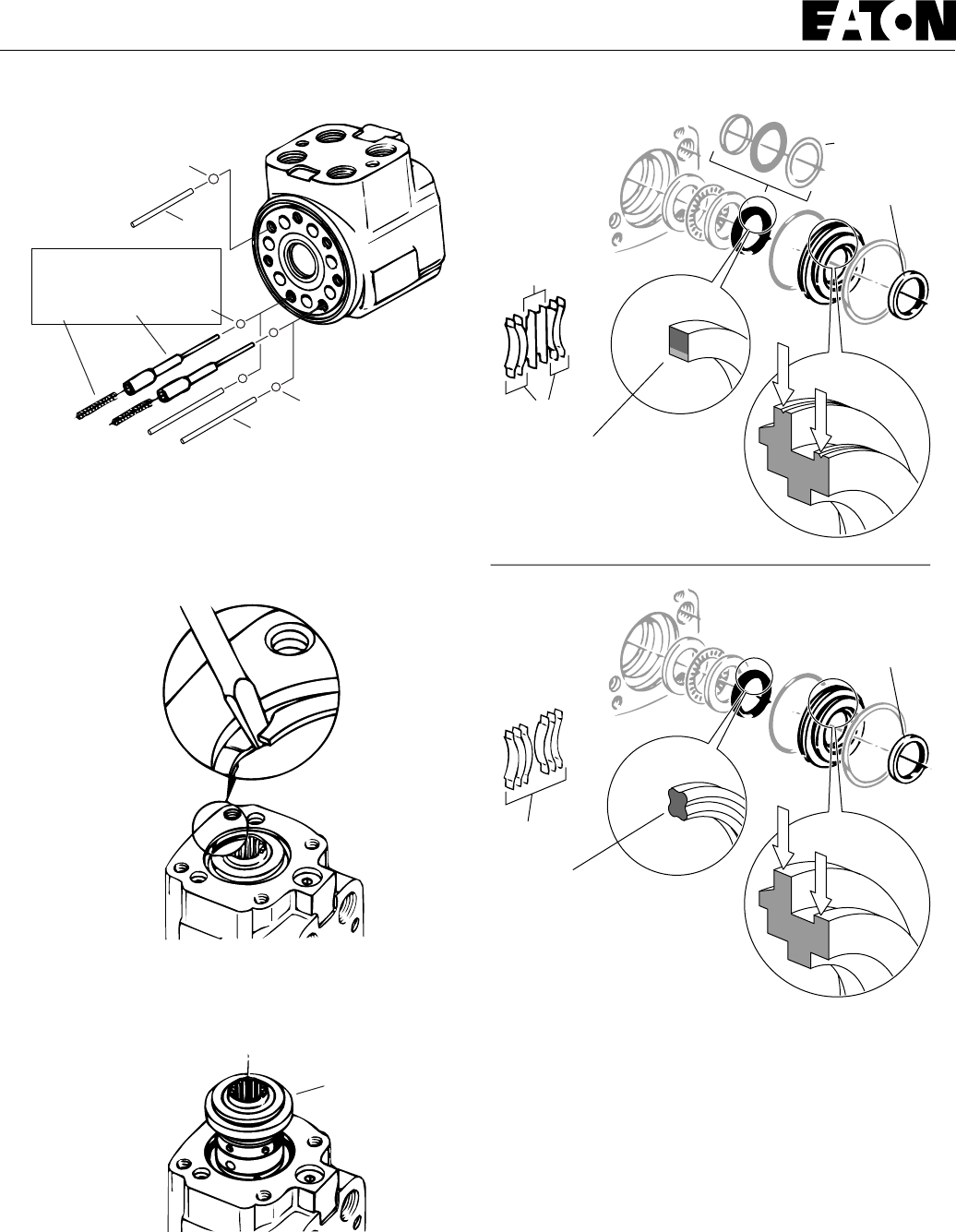

12 Carefully remove anti-cavitation valves and manual steering check

valve (roll pin and ball – if applicable) from bolt holes by tipping

housing as shown (see figure 5).

Control End

Seal Gland Bushing

Special Seal Gland Marked

with Groove for Identification

Replacement

Teflon Seal (1 Piece)

Springs (4)

Spring

Spacers (2)

Low Input

Torque

Steering

Control

Units

Old 3 Piece

Teflon Seal

Standard Seal

Gland Not Marked

with Groove (Special Seal

Gland Shown with Groove Above)

Quad Ring Seal

Springs (6)

Standard Input

Torque

Steering

Control

Units

Dust Seal

Dust Seal

13 Place housing on clean soft cloth, gerotor end down, to protect

surface finish. Use thin bladed screwdriver to pry retaining ring from

housing, as shown in figure 6.

14 Lift spool and sleeve assembly up just far enough to free gland

bushing from housing (figure 7). Remove bushing.

Note: Examine bushing to determine whether you are repairing low

torque or standard torque unit. Low torque unit has grooves on seal

gland bushing while standard torque unit has no grooves on bushing.

Seal gland bushings for low input torque and standard torque units are

not interchangeable

(see figure 8).

15

Low Input Torque Units:

Remove back-up ring, o-ring and Teflon

seal from seal gland bushing.

Standard Input Torque Units:

Remove

quad ring seal from seal gland bushing.

16 Use thin bladed screwdriver to pry dust seal from seal gland

bushing. Do not damage bushing.

Disassembly

Figure 5

Figure 6

Figure 7

Figure 8

Ball

Ball

Ball

Roll Pin

Roll Pin

Retainer Plug

Spring

Early Units

*

Built

with these Parts

*

Anti-Cavitation Valves

for Cylinder Ports

Manual Steering Check

Valve (when applicable)