Installation and Configuration

Liebert

®

GXT3

™

12

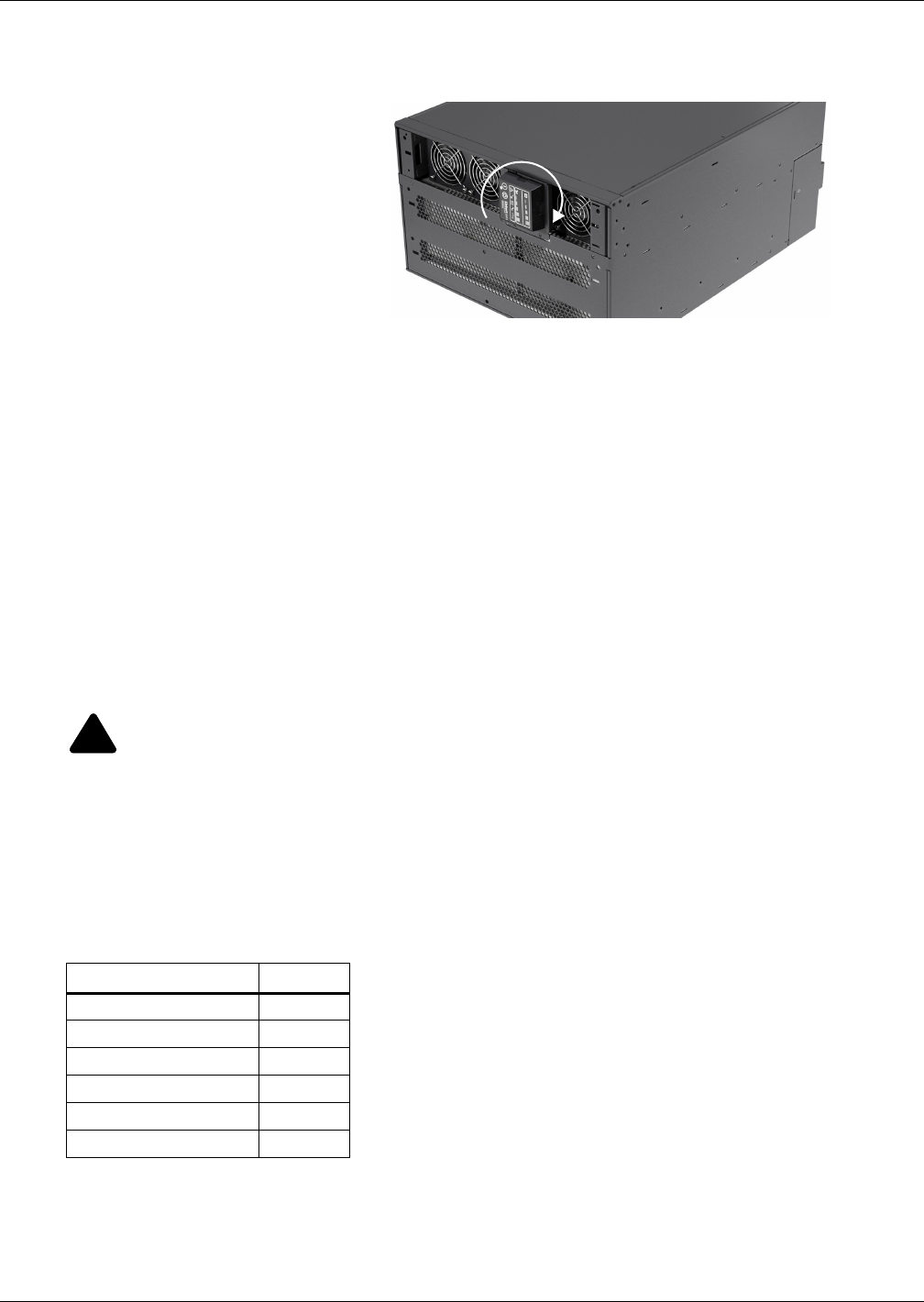

b. Pull the operation and display panel gently, rotate it 90 degrees clockwise and snap it back

into position, as shown in Figure 8.

Figure 8 Rotate the operation and display panel

c. Pull the logo on the front plastic bezel cover gently, rotate it 90 degrees clockwise and snap it

back into position. The rotated front plastic bezel cover is shown in Figure 8.

d. Replace the front plastic bezel cover on the Liebert GXT3. At this point, the UPS operation

and display panel and logo have been rotated 90 degrees clockwise, which provides upright

viewing for users.

5. Place the Liebert GXT3 and any battery cabinets on the support bases. Each Liebert GXT3 needs

two support assemblies, as shown in the lower half of Figure 1.

5.1.2 Rack-Mount UPS Installation

When using the Liebert GXT3 in a rack-mount configuration, the UPS must be supported by a slide

kit, fixed rails or a shelf.

When using the optional Adjustable Rack Mount Kit, you will use the following instructions. The

figures accompanying 5.1.3 - Installing the Adjustable Rack-Mount Kit—Sold Separately

shows the positioning of the rack-mounting brackets. Emerson® recommends taking the internal

batteries out of the UPS during rack installation. This will make the UPS cabinet lighter and easier

to handle.

5.1.3 Installing the Adjustable Rack-Mount Kit—Sold Separately

This kit contains parts needed to mount several different models of UPS and external battery

cabinets into EIA310-D standard four-post racks that are 18-32" deep (457-813mm). The weight limit

per pair of adjustable rack-mounting brackets is 91 kg (200lb).

Parts included are:

Tools needed for installation are:

• one Phillips screwdriver

• one 7mm wrench

!

CAUTION

The GXT3 is heavy; see 12.0 - Specifications. The UPS must be installed as near the bottom

of a rack as possible. If placed too high, it can make the rack top-heavy and prone to tipping

over.

Item Quantity

Rear bracket members 2

Front bracket members 2

Inner bracket members 2

M4 machine screws 16

M4 locking hex nuts 8

M5 machine screws 8

Operation and Display

Panel Rotated

Clockwise 90 Degrees