EPSON

EPSON AMERICA, INC.

SERVICE

PRODUCT SUPPORT BULLETIN

PSB NO.: P-0020

DATE: 5/6/88

PAGE: 1 of 2

SUBJECT: LQ-850/1050 PAPER THICKNESS LEVER

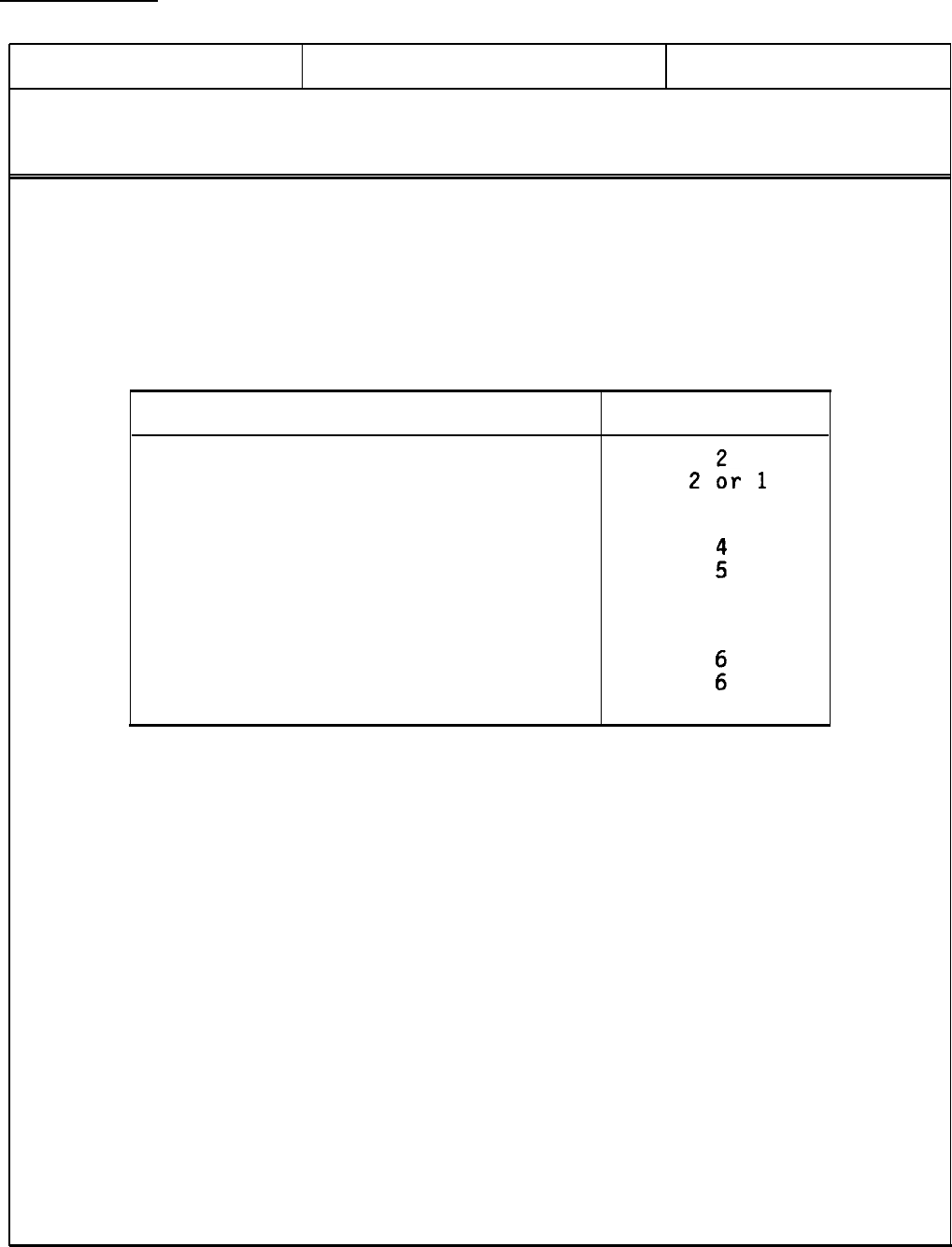

Reports from the field and from various repair locations show

that a large percentage of print head failures could be caused by

an incorrect paper thickness setting. The following table shows

general guide lines for selecting the correct lever position to

match your paper usage.

PAPER TYPE

LEVER POSITION

Single Sheet or Continuous

Thin paper

2

Er

1

Multi-Part

2 sheet

3

3 sheet

4 sheet

:

Labels

4

Envelopes

Airmail

4 or 5

Plain

Bond (20 lb.)

;

Bond (24 lb.)

7

The higher the number, the thicker the paper. The lever adjusts

the distance between the platen and the print head. If the lever

is set beyond the recommended position, the dot wire will extend

further from the face of the printhead, put stress on the wire,

and increase the possibility of dot wire damage. Over adjusting

to improve print darkness,

needs replacing,

using an old ribbon that needs

can damage the printhead.

Using the recommended lever setting will provide the longest life

to the print head and the best possible print quality.

Figure 1.1 shows the location of the lever on the LQ-850/1050

printer. Figure 1.2 shows a label that will be added to future

LQ-850/1050 printers to further emphasize the correct lever

setting.

EPSON AMERICA SERVICE, 23610 TELO AVENUE, TORRANCE, CALIF. 90505