Epson STYLUS NX100/NX105/SX100/SX105/TX100/TX101/TX102/TX103/TX105/TX106/TX109/ME 300 Revision A

DISASSEMBLY/ASSEMBLY Disassembling the Printer Mechanism 83

Confidential

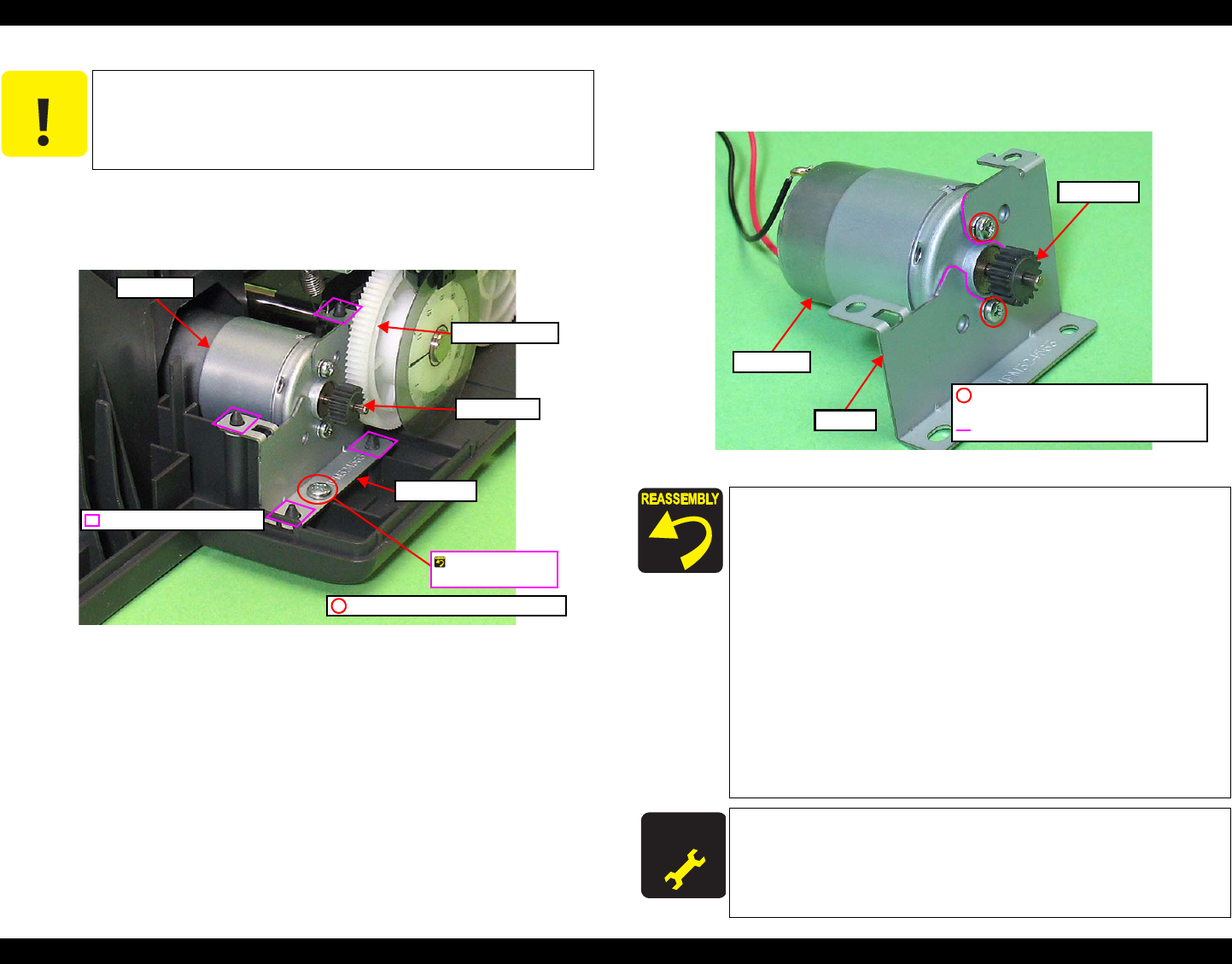

3. Remove the screw that secures the Bracket.

4. Release the Bracket from the dowels of the Lower Housing, and remove the

Bracket and the PF Motor while pulling out the PF Motor Cable (see

Fig.4-67.) through the hole of the Lower Housing.

Figure 4-69. Removing the PF Motor (3)

5. Remove both the screws that secure the PF Motor.

6. Remove the PF Motor pulling out the shaft of the motor through the notch of

the Bracket.

Figure 4-70. Removing the PF Motor (4)

C A U T I O N

Do not damage the PF Roller Gear.

Do not damage the Pinion Gear.

Be careful of not to break the soldered portions.

Positioning Hole and Dowel

Bracket

PF Motor

PF Roller Gear

Pinion Gear

SCREW M3x8 P-TITE (5±0.5kgfcm)

Screw it with the

Grounding Wire.

When installing the PF Motor, insert the black cable over the

red one. (See

Fig.4-70.)

Install the Grounding Spring as follows: (See Fig.4-68.)

1. Insert the tip of the spring to the hole of the Lower Housing.

2. Attach the eyes of the spring to the hook of the Main Frame

and that of the Bracket to secure it.

Before securing the Bracket, align the four positioning holes of

it with the four dowels of the Lower Housing. (See

Fig.4-69.)

Don not damage the PF Roller Gear and the Pinion Gear.

Route the PF Motor Cable following the procedure below. (See

Fig.4-67.)

1. When pulling out the cable from the hole of the Lower

Housing, give the cable some slack to prevent breaking the

soldered portions.

2. Route the cable through the rib.

A D J U S T M E N T

R E Q U IR E D

Whenever the PF Motor removed/replaced, the required

adjustments must be carried out.

• Chapter 5 “ ADJUSTMENT” (p.100)

PF Motor

Bracket

Pinion Gear

SCREW SEMS M2.6x3.5 PAN HEAD+

(3.5±0.25kgfcm)

Notch