4

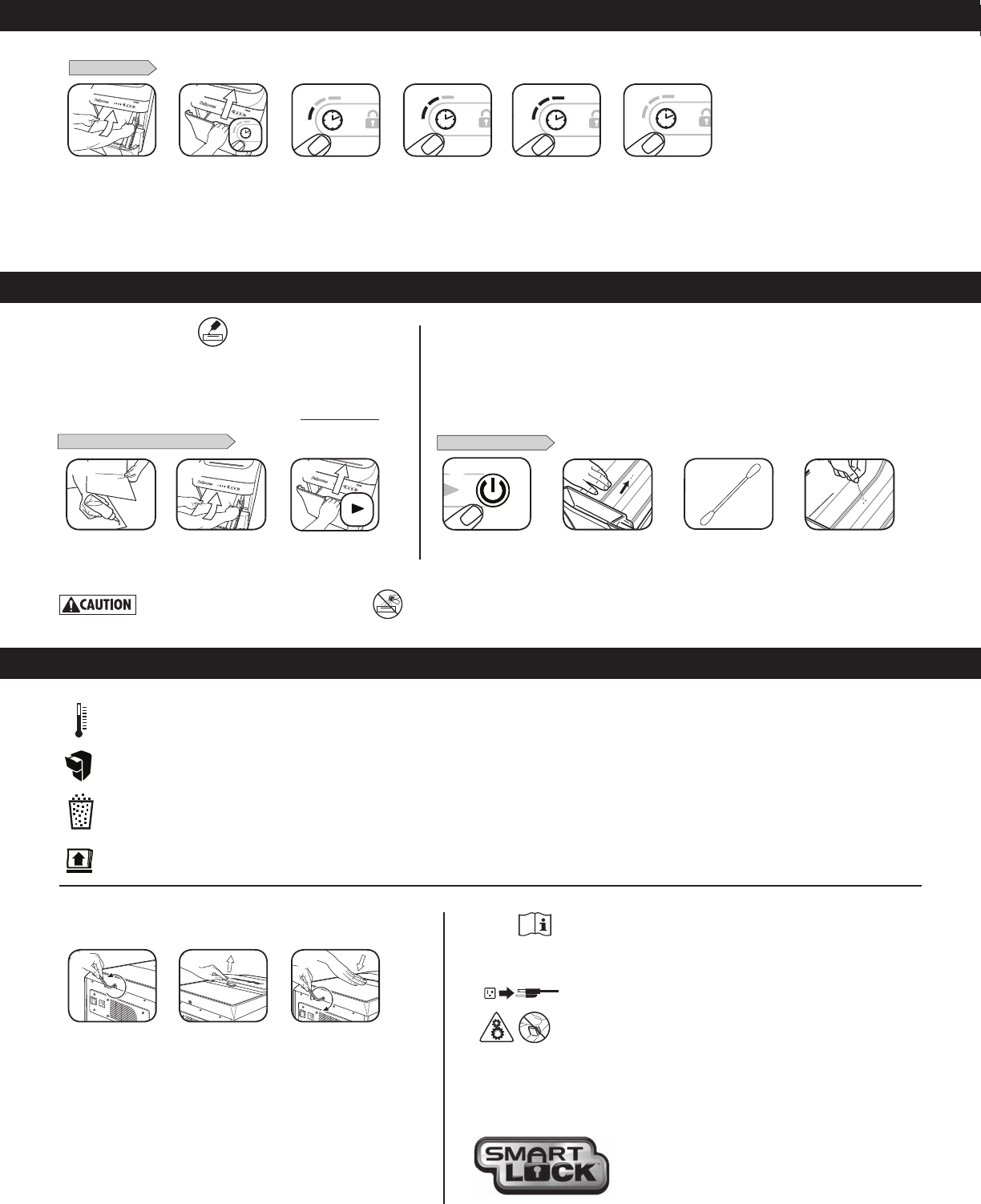

DELAYED START (ON 500C ONLY)

DELAYED START

Close drawer and

press clock icon on

control panel

Press once for

30 minute delay

(one LED will

illuminate)

Press twice for

60 minute delay

(two LEDs will

illuminate)

Press three times for

90 minute delay

(three LEDs will

illuminate)

Press four times to

reset clock

Allows you to delay shredding for 30, 60 or 90 minutes.

If a critical situation occurs while SmartLock™ is engaged and the shredder drawer

needs to be accessed, follow the steps below.

In case of a power outage, SmartLock™ will remain engaged.

Once power is restored, shred cycle will automatically resume.

**To cancel Delayed Start, press and hold Clock icon for 2 seconds

* Shredder will not run if the hatch is not in place. Always replace the

hatch to resume shredding.

Open drawer and

add paper. (Note: Pull

firmly to open drawer)

Locate the access

screw on the back of

the machine and turn

counter clockwise with

a 6mm allen wrench.

1 2

TROUBLESHOOTING

Overheat Indicator: When the Overheat Indicator is illuminated, the shredder has exceeded its maximum operating temperature and needs to cool down. This indicator

will remain illuminated and the shredder will not operate for the duration of the recovery time.

#JO'VMM8IFOJMMVNJOBUFEUIFTISFEEFSXBTUFCJOJTGVMMBOEOFFETUPCFFNQUJFE6TF'FMMPXFTXBTUFCBH

Drawer/Bin Door Open: The shredder will not run if the bin is open. When illuminated, close the bin to resume shredding.

Remove Paper: When illuminated, see Paper Jam section under Advanced Product Features.

1

The service hatch

will begin to rise.

,FFQUVSOJOHVOUJM

the hatch panel

is easily removed

from the top of the

machine.

3

To replace the service

hatch, position hatch

panel back on top of

the machine. Hold

panel in place while

turning the allen

wrench clockwise until

you feel resistance.

2

PRODUCT MAINTENANCE

TO CLEAN THE SENSORS

CLEANING AUTO-START INFRARED SENSORS

Paper detection sensors are designed for maintenance free operation. However, on rare occasions the sensors

may become blocked by paper dust causing the motor to run even if there is no paper present.

(Note: two paper detection sensors are located at the bottom of the paper drawer).

"MMDSPTTDVUTISFEEFSTSFRVJSFPJMGPSQFBLQFSGPSNBODF6OEFSPSPWFSPJMJOHB

machine could lead to issues such as diminished sheet capacity, intrusive noise

when shredding and it could ultimately stop running. To avoid these problems, we

recommend you oil your Fellowes

®

AutoMax™ shredder once per month.

OILING SHREDDER

* Only use a non-aerosol vegetable oil in long

nozzle container such as Fellowes 35250.

FOLLOW OILING PROCEDURE BELOW

Turn off and unplug

shredder

Locate Auto-start

infrared sensor

6TJOHDPUUPOTXBCXJQF

away any contamination

from the paper sensors

Dip cotton swab in

rubbing alcohol

Open paper feed drawer

and place oiled sheets in

drawer

Close the paper feed

drawer and press start to

shred the oiled sheets

Apply a light coat of

oil between two sheets

of paper

2

1

3

1

2 4

3

t 0QFSBUJPONBJOUFOBODFBOETFSWJDFSFRVJSFNFOUTBSFDPWFSFEJO

the instruction manual. Read the entire instruction manual before

operating shredders.

t "WPJEUPVDIJOHFYQPTFEDVUUJOHCMBEFTHFBSTBOEUBDLTVOEFS

shredder head or feed arms.

t 6OQMVHTISFEEFSCFGPSFDMFBOJOHPSTFSWJDJOH