C141-E072-01EN 4 - 13

4.6.4 Time base generator circuit

The drive uses constant density recording to increase total capacity. This is different from the

conventional method of recording data with a fixed data transfer rate at all data area. In the

constant density recording method, data area is divided into zones by radius and the data

transfer rate is set so that the recording density of the inner cylinder of each zone is nearly

constant. The drive divides data area into 15 zones to set the data transfer rate. Table 4.2

describes the data transfer rate and recording density (BPI) of each zone.

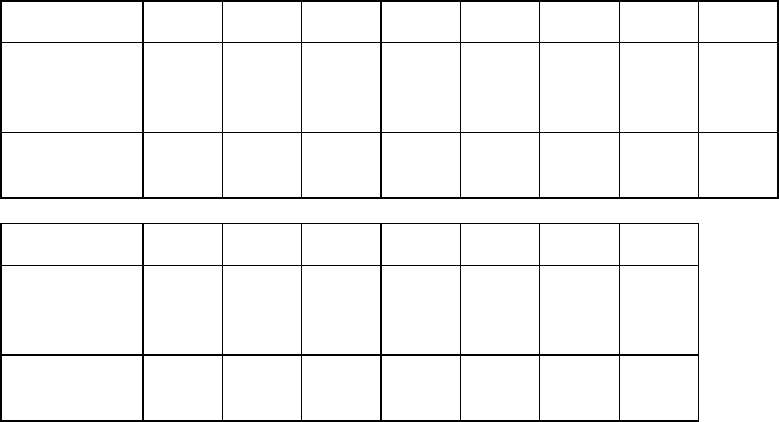

Table 4.2 Write clock frequency and transfer rate of each zone

Zone 0 1 2 3 4 5 6 7

Cylinder 0

to

1308

1309

to

2616

2617

to

3914

3915

to

4868

4869

to

5648

5649

to

6328

6329

to

7468

7469

to

8248

Transfer rate

[MB/s]

34.67 34.67 34.67 33.57 32.66 31.76 30.25 29.18

Zone 8 9 10 11 12 13 14

Cylinder 8249

to

8638

8639

to

9418

9419

to

10008

10009

to

10598

10599

to

11525

11526

to

12162

12163

to

12554

Transfer rate

[MB/s]

28.63 27.53 26.62 25.70 24.20 23.14 21.47

The MPU transfers the data transfer rate setup data (SDATA/SCLK) to the RDC that includes

the time base generator circuit to change the data transfer rate.

4.7 Servo Control

The actuator motor and the spindle motor are submitted to servo control. The actuator motor

is controlled for moving and positioning the head to the track containing the desired data. To

turn the disk at a constant velocity, the actuator motor is controlled according to the servo data

that is written on the data side beforehand.