Generac

®

Power Systems, Inc. 3

2.1 INTRODUCTION TO INSTALLATION

This equipment has been wired and tested at the

factory. Installing the switch includes the following

procedures:

• Mounting the enclosure.

• Connecting power source and load leads.

• Connecting the generator start circuit.

• Connecting any auxiliary contact (if needed)

• Installing/connecting any options and accessories.

• Testing functions.

2.2 UNPACKING

Carefully unpack the transfer switch. Inspect closely

for any damage that might have occurred during

shipment. The purchaser must file with the carrier any

claims for loss or damage incurred while in transit.

Check that all packing material is completely

removed from the switch prior to installation.

2.3 MOUNTING

Mounting dimensions for the transfer switch

enclosure are in this manual. Enclosures are

typically wall-mounted. See “Mounting Dimensions”.

Handle transfer switches carefully when

installing. Do not drop the switch. Protect the

switch against impact at all times, and against

construction grit and metal chips. Never

install a transfer switch that has been

damaged.

Install the transfer switch as close as possible to the

electrical loads that are to be connected to it. Mount

the switch vertically to a rigid supporting structure.

To prevent switch distortion, level all mounting

points. If necessary, use washers behind mounting

holes to level the unit.

2.4 CONNECTING POWER SOURCE

AND LOAD LINES

Make sure to turn OFF both the UTILITY

(NORMAL) and EMERGENCY (STANDBY)

power supplies before trying to connect

power source and load lines to the transfer

switch. Supply voltages are extremely high

and dangerous. Contact with such high

voltage power supply lines causes extremely

hazardous, possibly lethal, electrical shock.

Wiring diagrams and electrical schematics are

provided in this manual. Power source and load

connections are made at a transfer mechanism,

inside the switch enclosure.

2.4.1 2-POLE MECHANISM

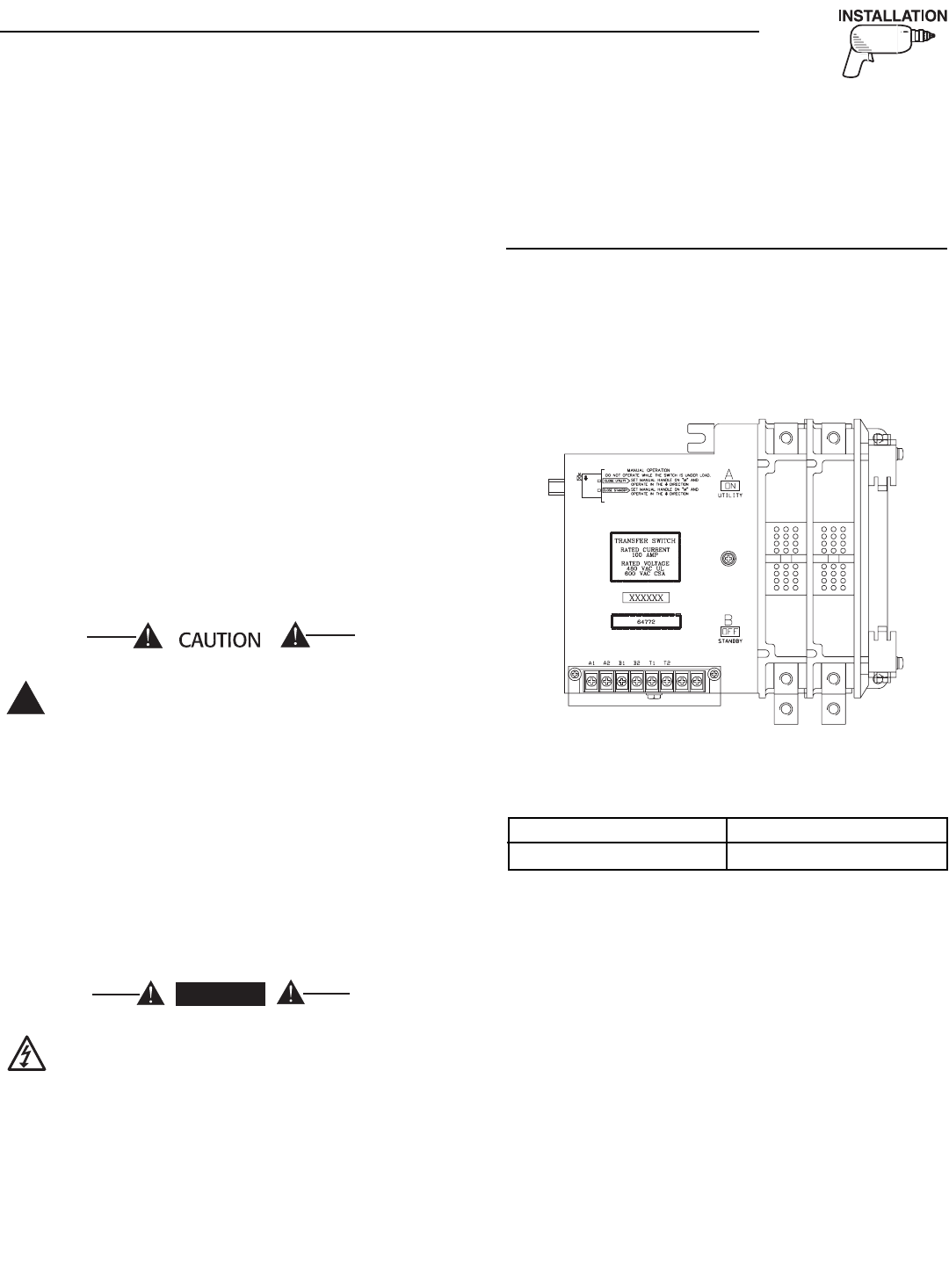

These switches (Figure 2.1) are used with a single

phase system, when the single phase NEUTRAL line

is to be connected to a Neutral Lug and is not to be

switched.

Figure 2.1 — Typical 2-Pole Transfer Mechanism

(100 Amp Shown)

Solderless, screw-type terminal lugs are standard.

The conductor size range is as follows:

Conductor sizes must be adequate to handle the

maximum current to which they will be subjected;

based on the 75°C column of tables, charts, etc. used

to size conductors. The installation must comply fully

with all applicable codes, standards and regulations.

Before connecting wiring cables to terminals, remove

any surface oxides from the cable ends with a wire

brush. All power cables should enter the switch next

to transfer mechanism terminals. If ALUMINUM

conductors are used, apply corrosion inhibitor to

conductors. Tighten terminal lugs to the torque

values as noted on the decal located on the inside of

the door. After tightening terminal lugs, carefully wipe

away any excess corrosion inhibitor.

All power cables should enter the switch next to the

transfer mechanism terminals.

DANGER

!

Section 2 — Installation

Generac GTS “W” Type Transfer Switch

Switch Rating Wire Range

200A #4-400 MCM