4 308703

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

When pumping flammable fluids, the

surge suppressor must be grounded.

Before pumping, ground the system as

explained below. Also read the section

FIRE OR EXPLOSION HAZARD on

page 3.

Polypropylene surge suppressors are not

conductive. Attaching the ground wire to the

grounding lug grounds only the clamp or flange

(see Fig. 1). When pumping conductive flammable

fluids, always ground the entire fluid system by

making sure the fluid has an electrical path to a

true-earth ground.

To reduce the risk of static sparking, ground the surge

suppressor and all other equipment in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equip-

ment. Ground all of this equipment:

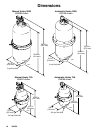

D Surge suppressor: Attach a ground wire to the

grounding lug (2) as shown in Fig. 1. Connect the

clamp end of the ground wire to a true earth

ground. To order a ground wire and clamp, order

Part No. 222011.

NOTE: To connect the ground wire to the surge

suppressor, first remove the copper connector from

the non-clamp end of the ground wire and discard

it, then push the bare wire through the grounding

lug on the surge suppressor.

D Fluid supply container: Follow your local code.

Fig. 1

23

2

NOTE: When pumping conductive flammable fluids

with a surge suppressor, always ground the entire

fluid system. See the WARNING at left. Fig. 2

shows recommended methods of grounding fluid

containers during filling. These are only guides;

contact your Graco distributor for assistance in

grounding your system.

D Air compressor: Follow the manufacturer’s

recommendations.

D Solvent pails used when flushing: Follow your local

code. Use only grounded metal pails, which are

conductive. Do not place the pail on a

non-conductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.