6 308178

Installation

General Information

The surge suppressor uses air pressure and a

diaphragm to maintain a consistent fluid outlet

pressure from a double diaphragm or low-pressure

reciprocating pump. During normal flow, the

suppressor air pressure and fluid pressure are in

equilibrium. A sharp increase in fluid pressure causes

the air inlet port to open, increasing air pressure on the

diaphragm and returning the system to equilibrium.

Conversely, a sharp decrease in fluid pressure causes

the air exhaust port to open, decreasing air pressure

on the diaphragm and allowing the system to return to

equilibrium.

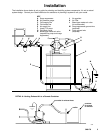

Installation

1. Read this entire manual before installing or

operating the surge suppressor.

2. The surge suppressor fluid inlet must be

connected to the pump’s fluid outlet. If the pump

is aluminum or steel, the surge suppressor may

be plumbed directly to the outlet, using 3/4 npt

fittings. If the pump is acetal or polypropylene,

place the surge suppressor on the floor or some

other solid, level surface near the pump, and

connect the surge suppressor inlet to the pump

outlet with a 3/4” ID hose and 3/4 npt fittings.

CAUTION

Do not plumb the surge suppressor directly onto the

fluid outlet of an acetal or polypropylene pump.

Those pumps cannot support the weight of the

suppressor and will suffer damage or rupture.

3. Connect an air line from the pump’s air regulator to

the air inlet of the surge suppressor. In systems

using a 1:1 ratio pump, the air pressure supplied to

the suppressor will be the same as that supplied to

the pump.

4. Use a compatible, liquid thread sealant on all male

threads. Tighten all connections firmly to avoid air

or fluid leaks.

CAUTION

To avoid pump damage, do not overtighten the

fittings to the pump.

Air Exhaust Ventilation

WARNING

Be sure to read TOXIC FLUID HAZARD and FIRE

AND EXPLOSION HAZARD on page 3, before

operating this equipment.

Be sure the system is properly ventilated for your

type of installation. When pumping flammable or

hazardous fluids, you must vent the surge suppres-

sor exhaust air to a safe place, away from people,

animals, food handling areas, and all sources of

ignition. If the diaphragm ruptures, the fluid will be

exhausted along with the air. Place a container at

the end of the air exhaust line to catch the fluid.

See Detail A on page 5.

The minimum size for the air exhaust hose is 3/8 in.

(10 mm) ID x 15 ft (4.6 m). If a longer hose is required,

use a larger diameter hose.

1. Remove the muffler from the surge suppressor

exhaust port. Install an exhaust hose in the

exhaust port, and connect the muffler to the other

end of the hose. Avoid sharp bends or kinks in the

hose. See Detail A on page 5.

2. Place a container at the end of the air exhaust line

to catch fluid in case the diaphragm ruptures.

WARNING

Never operate the surge suppressor without the

muffler or an air exhaust line installed in the air

exhaust port. If the air exhaust port is left open and

the diaphragm shaft works loose from the bolt, the

shaft could be propelled out of the housing, caus-

ing injury.