SERIES 90 MODUTROL IV™ MOTORS

5 63-2190—3

Table 5. Series 90 Modutrol Motor Timing and Torque Ratings.

a

Timings apply to all TRADELINE models. Some OEM models are available with non-standard timing/torque.

b

The torque rating for dual-ended shaft motors is the sum of the shaft torques (power-end torque plus auxiliary-end torque).

c

Breakaway torque is maximum torque available to overcome occasional large loads such as a seized damper or valve.

d

Low timing is for M9184D1005 only.

NOTE: Some 150 lb-in. and 300 lb-in. torque adjustable stroke motors have timings that are twice that of their fixed stroke

counterparts.

IMPORTANT

Never use a Modutrol Motor continuously at the Breakaway Torque rating.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

IMPORTANT

Always conduct a thorough checkout when

installation is complete.

Location

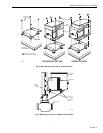

Allow enough clearance for installing accessories and motor

servicing when selecting a location (see Fig. 1). If located

outdoors, use liquid-tight conduit connectors with the junction

box to provide NEMA 3 weather protection. If mounted

outdoors in a position other than upright, install a 4074ERU

Weatherproofing Kit and liquid-tight connectors to provide

NEMA 3 protection.

CAUTION

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

In excessive salt environments, mounting base and screws

should be zinc or cadmium plated, not stainless steel or brass.

Use the 220738A Adapter Bracket for mounting on these

surfaces.

Mounting

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Always install motors with the crankshaft horizontal.

Improper motor mounting can result in inadequate

motor gear train lubrication.

Use the following guidelines for proper motor mounting:

• Always install motors with the crankshaft horizontal.

• Mounting flanges extending from motor housing base are

drilled for 1/4 inch (6.4 mm) machine screws or bolts.

• Non-Spring Return Motors are shipped from the factory in

the closed position (at the limit of counterclockwise

rotation, as viewed from the power end of the motor).

• Spring Return Motors are shipped from the factory in their

normal position:

— Normally closed models: shipped at limit of

counterclockwise rotation, as viewed from the power

end of the motor.

— Normally open models: shipped at limit of clockwise

rotation, as viewed from the power end of the motor.

NOTE: Refer to Fig. 2 for graphical representation of full

open and full closed.

Nominal Timing

a

in sec

Rated Torque in lb-in. (N•m)

b

Normal Running Torque Breakaway Torque

c

90° 160° Spring Return Non-Spring Return Spring Return Non-Spring Return

30 60 25 (2.8) 35 (4) 50 (5.7) 70 (8)

15

d

/30 30

d

/60

60 (6.8) 75 (8.5) 120 (13.6) 150 (17)

30 60 — 150 (17) — 300 (34)

60 120 — 300 (34) — 600 (68)