PEXXP-XXX-XXX-XXXX (en) Page 8 of 16

END OF STROKE

GENERAL DESCRIPTION

With end of stroke feedback from a pressure switch, the

solenoid can be used to cycle the pump based on known feed-

back that the pump has fully completed each stroke.

PRESSURE SWITCH OPERATION

A calibration procedure is necessary for proper operation of

the pressure switch and accurate end of stroke feedback from

the pump. The Reset ring will always have a lower pressure

value than the Set ring.

Determine the operating air pressure of the pump.

The Reset ring should be set to approximately 25% of the

operating pressure of the pump with a minimum of 10 PSI.

The Set ring should be set to approximately 50% of the

operating pressure of the pump. This value is more vari-

able depending on the specic operating conditions. The

switch may function properly at much lower values for

the Set ring if the pump is running slowly, or at lower op-

erating pressures. In general, high operating speeds and

pressures require a higher setting value of the Set ring.

Operate the pump slowly to ensure proper operation of

the pressure switch. When the pump has shifted to one

side, the yellow LED will illuminate and remain on until

the pump shifts back to the opposite side.

If the operating pressure of the pump changes, the

Set ring may need to be adjusted accordingly.

1.

2.

3.

4.

5.

SETTING / OPERATION

9.6 to

32 V

DC

1

2

Set

Reset

3

4

7

6

5

pnp

pnp

500mA

500mA

2

1

3

4

-

+

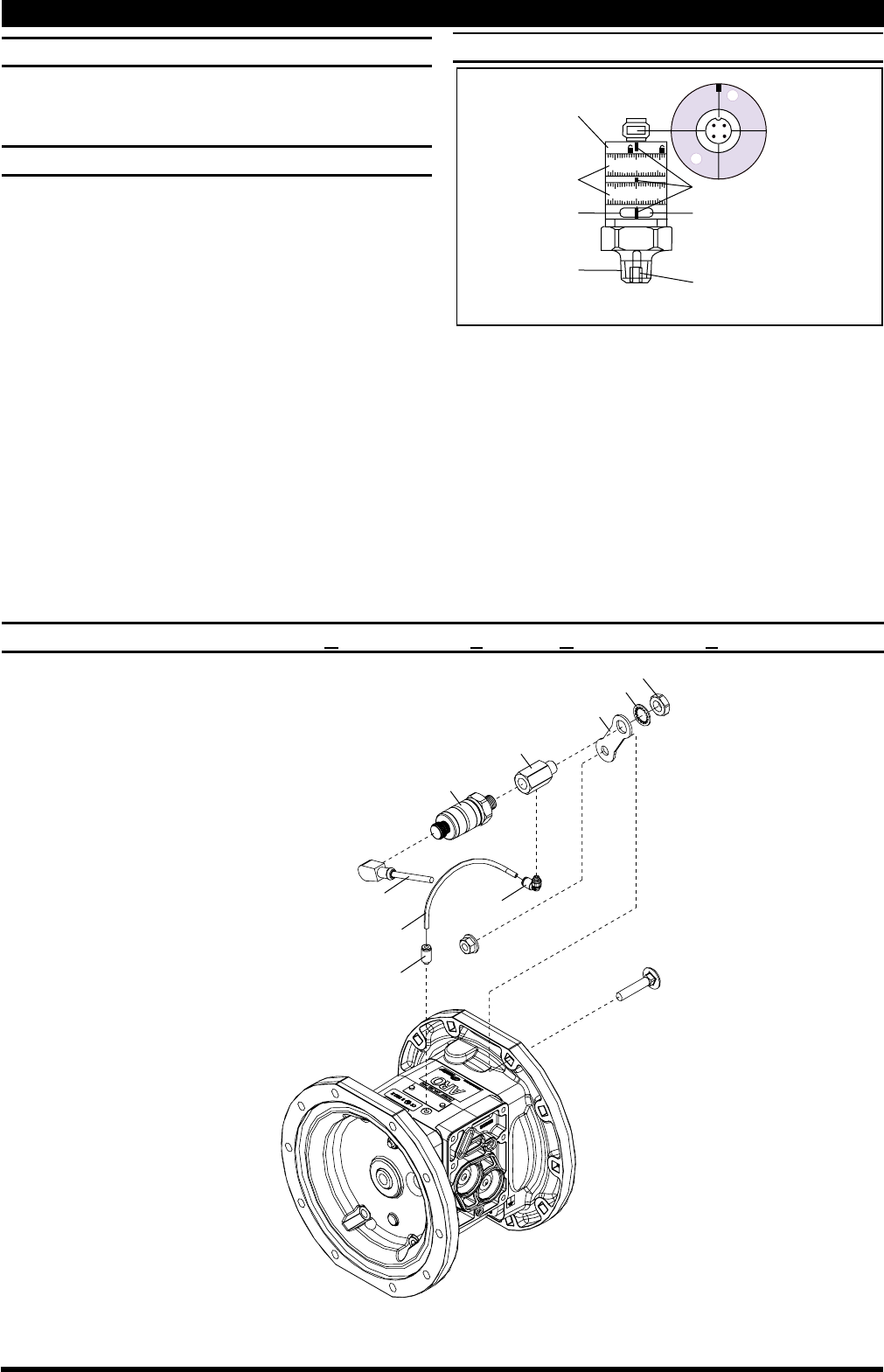

Locking Ring

Setting Rings (manually adjustable after unlocking)

LED green: supply voltage O.K.

Process connection ¼” NPT; tightening torque 25 Nm

Setting Marks

LED yellow: Set values reached, OUT1 = ON / OUT2 = OFF

Internal Thread M5

Minimum distance between Set and Reset = 2% of the

nal value of the measuring range.

To obtain the setting accuracy: Set both rings to the mini-

mum value, then set the requested value.

1.

2.

3.

4.

5.

6.

7.

PART LIST / PEXXXXXXXXXXXEX, PEXXXXXXXXXXXFX

Figure 5

Figure 6

423

424

426

422

427

412

408

405

404