©Eastman Kodak Company, 2001

January 2003 • E-142

TECHNICAL DATA / COLOR PAPER

KODAK PROFESSIONAL

ULTRA III Paper

KODAK PROFESSIONAL ULTRA III Paper is a fast,

resin-coated multilayer paper for optical printing of color

negatives or internegatives. It provides the higher contrast

needed for such commercial applications as

point-of-purchase and trade-show materials and large

display prints. It offers consistent, high-quality output for

greater productivity and less waste. It is optimized for

commercial applications and is designed for printing with

automatic printers or enlargers.

Use KODAK EKTACOLOR RA Chemicals for Process

RA-4 to process this paper.

This paper replaces KODAK EKTACOLOR ULTRA II

Paper. It is available in sheets and rolls in F (glossy),

E (fine lustre), and N (smooth lustre) surfaces.

ULTRA III Paper incorporates a number of technical

improvements. It provides higher color saturation and more

accurate colors than EKTACOLOR ULTRA II Paper. Labs

will benefit from its improved latent-image keeping, reduced

heat sensitivity, and excellent print consistency due to

improved reciprocity.

Compared to EKTACOLOR ULTRA II Paper, this paper

offers these features:

—NOTICE—

KODAK PROFESSIONAL ULTRA ENDURA Paper replaces

KODAK PROFESSIONAL ULTRA III Paper. ULTRA ENDURA

Paper also provides an alternative to KODAK PROFESSIONAL

Digital III Color Paper

FEATURES BENEFITS

•Improved color

reproduction

• More accurate reds, greens,

and magentas

• Brighter blues and cyans

• More saturated yellows

• Improved highlight

reproduction

• Truer reproduction of high-key

scenes

• Cleaner highlights

• Improved shadow

rendition

• More retention of detail in

shadows

• Excellent reciprocity

characteristics

• Easier matching of color

balance and saturation in prints

regardless of the degree of

enlargement

• Improved first-print yield from

under- and overexposed

negatives

• Easier dodging and burning

• Faster red printing speed • Higher productivity for

enlargements

STORAGE AND HANDLING

Store unexposed paper at 13°C (55°F) or lower in the

original sealed package. High temperatures or high humidity

may produce unwanted quality changes.

To avoid moisture condensation on paper that has been

refrigerated, allow it to warm up to room temperature before

opening the package. For best results, remove the paper from

cold storage the day before you use it, or allow the paper to

warm up for the appropriate time from the following table.

Handle paper carefully by the edges. The paper is

packaged with the emulsion side of all sheets facing in the

same direction. For complete light and moisture protection,

use the inner bag and the two-part cardboard box to store the

paper.

• Excellent latent-image

keeping from 1 minute to

24 hours

• Improved processing

consistency in the lab

• Optimized spectral

sensitivity

• Better alignment between

paper, film dyes, video

analyzer, and printer spectral

response

• Improved printing compatibility

and image quality with KODAK

PROFESSIONAL Films

• Elimination of print-out

and thermal yellowing

• Longer print life under dark

storage conditions

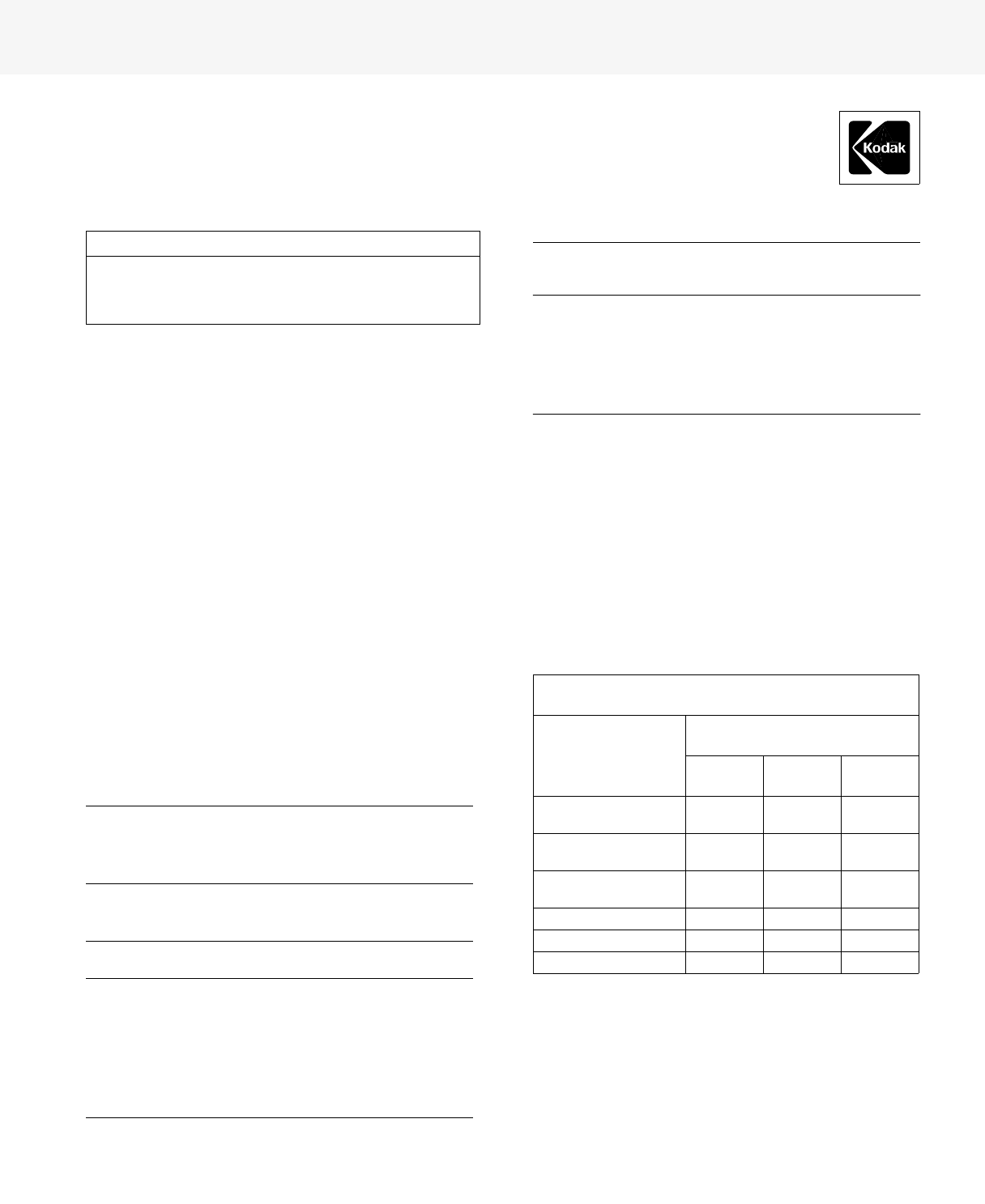

Warm-Up Times (Hours) to Reach

Room Temperature of 21°C (70°F)

Size

From a Storage

Temperature of

–18°C

(0°F)

2°C

(35°F)

13°C

(55°F)

8 x 10-inch

(100-sheet box)

432

16 x 20-inch

(50-sheet box)

322

20 x 24-inch

(50-sheet box)

322

8-inch x 575-foot roll 10 7 4

30-inch x 100-foot roll 8 6 4

40-inch x 100-foot roll 9 7 5

FEATURES BENEFITS