MC-42S CONCRETE MIXER — PARTS & OPERATION MANUAL — REV. #8 (12/16/05) — PAGE 25

Maintenance

Perform the scheduled maintenance procedures as defined by

Table 6 and below:

DAILY

■

Thoroughly remove dirt and oil from the engine and control

area. Clean or replace the air cleaner elements as necessary.

Check and retighten all fasteners as necessary. Check the

gearbox for oil leaks. Repair or replace as needed.

WEEKLY

■

Remove the fuel filter cap and clean the inside of the fuel

tank.

■

Remove or clean the filter at the bottom of the tank.

■

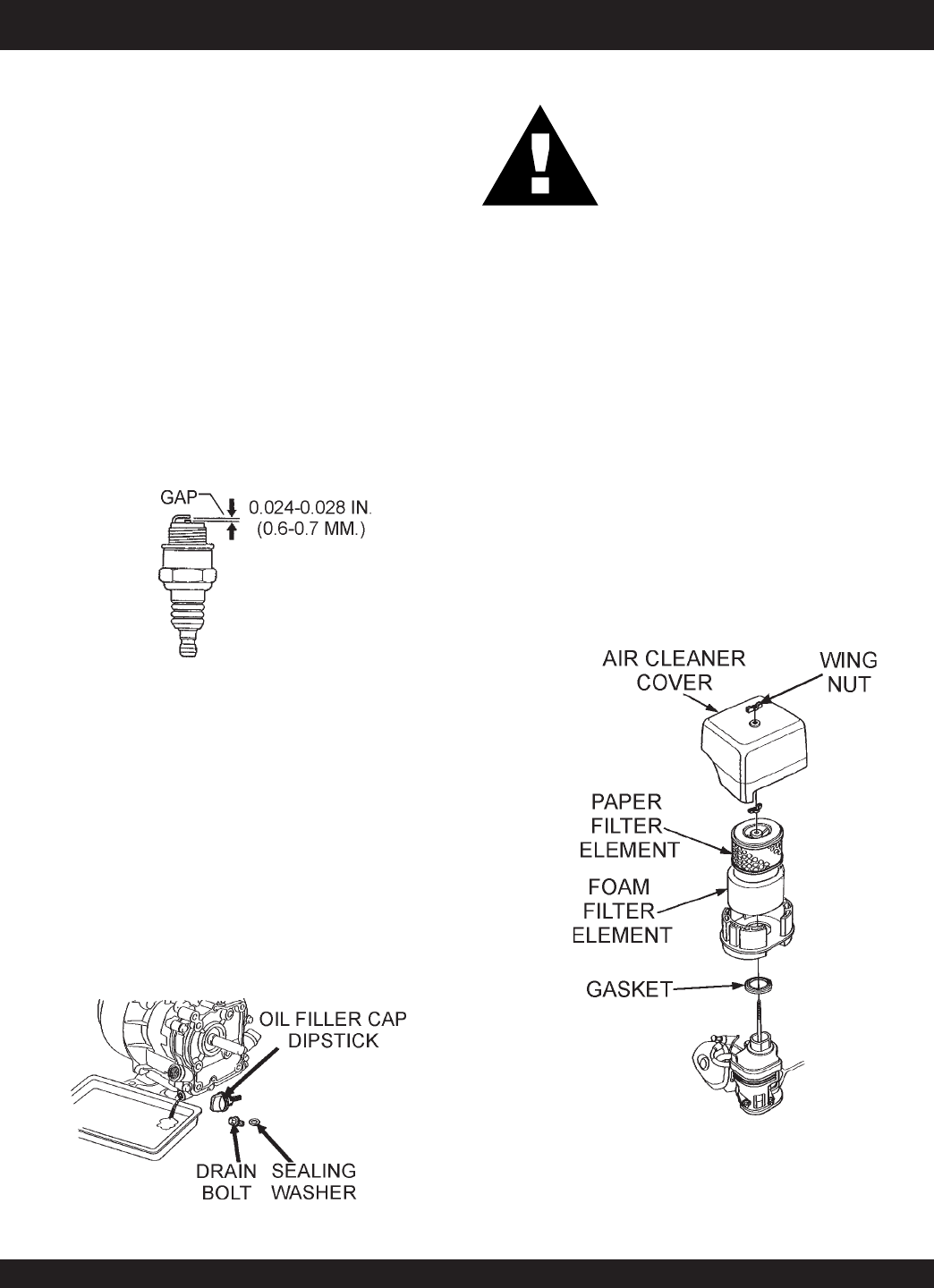

Remove and clean the spark plug (Figure 23), then adjust

the spark gap to 0.024 ~0.028 inch (0.6~0.7 mm). This unit

has electronic ignition, which requires no adjustments.

DO NOT use gasoline as a cleaning solvent,

because that would create a risk of fire or

explosion.

DANGER :

ENGINE OIL

1. Drain the engine oil when the oil is

warm

as shown in

Figure 24.

2. Remove the oil drain bolt and sealing washer and allow

the oil to drain into a suitable container.

3. Replace engine oil with recommended type oil as listed

in Table 5. For engine oil capacity, see Table 2 (engine

specifications). DO NOT overfill.

4. Install drain bolt with sealing washer and tighten se-

curely.

Figure 24. Engine Oil (Draining)

Figure 23. Spark Plug Gap

MC-42S CONCRETE MIXER — MAINTENANCE (ENGINE)

ENGINE AIR CLEANER

1. Remove the air cleaner cover and foam filter element as

shown in Figure 25.

2. Tap the paper filter element (Figure 25) several times on a

hard surface to remove dirt, or blow compressed air [not

exceeding 30 psi (207 kPa, 2.1 kgf/cm

2

)] through the filter

element from the air cleaner case side.

NEVER

brush off dirt.

Brushing will force dirt into the fibers. Replace the paper filter

element if it is excessively dirty.

3. Clean foam element in warm, soapy water or nonflammable

solvent. Rinse and dry thoroughly. Dip the element in clean

engine oil and completely squeeze out the excess oil from the

element before installing.

Figure 25. Engine Air Cleaner