Case: Die casted aluminum,

Dial: 4-1/2 in. (114 mm), white on black background.

Sensing Element: Bronze bourdon tube standard; 316 stainless steel or monel

are optional. 45LHEA and 45LHE Level models up to 20 ft. (6.09 m) brass

bellows is standard; stainless steel bellows is optional (see page 4).

Geared Movement: 302 and 304 stainless steel.

Lens: Clear Polycarbonate, UV stabilized, fog and scratch resistant.

SWICHGAGE

®

Sensor: PowerHall; outputs negative signal

(sinking transistor output) rated: 300 mA continuous.

SWICHGAGE

®

Set Points: 2-fingertip adjustable, visible on face-dial.

SWICHGAGE

®

Electrical Connection:

Surface Mount Case: Terminal block; 1/2 NPTF conduit connection.

Panel Mount Case: Wire leads, 18 AWG x 8 in. (1.0 mm

2

x 203 mm);

1/2 NPTM conduit connection.

Optional Conduit Connection: 24 AWG x 8 in. (0.22 mm

2

x 203 mm);

1/2 NPTM conduit connection.

Operating Temperature: -40 to 185°F (-40 to +85°C).

Storage Temperature: -77 to 185°F (-60 to 85°C).

Power Input: 4.5 to 28 VDC; 120 VAC/24VDC for Latching Control

Relay (BP) models with built-in transformer/rectifier.

Overrange: Do not exceed 30% above full range (all models).

Pressure Models Sensing Connection: Bottom connection 1/4 NPTM thru

1000 psi (6.89 MPa) [68.9 bar], or 1/2 NPTM 1500 psi (10.3 MPa) [103 bar]

thru 20,000 psi (137 MPa) [1378 bar], back connection optional.

Pressure Models Accuracy: ±2% for the first and last quarters of the scale,

the middle half of scale is ±1%.

Temperature Models Sensing Connections:

Capillary: 5 feet (1.5 m) PVC armored copper tube, standard.

(Other options available see “How to Order” section, page 4).

Sensing Bulb: Copper, 1/2 in. (13 mm) O.D. x 7 in. (178 mm) length;

600 psi (4.14 MPa) [41.37 bar] pressure rating, for higher pressure

ratings the use of thermowell is recommended.

Sensing Bulb Connection: 1/2 NPTM.

Level Models Sensing Connections:

45LHE, 45LHEF: Bottom connection 1/4 NPTM.

Bellows Mov. Models (up to 20 ft. [6 m] range): Bottom connection 1/4 NPTF.

45LHEFP: 2 NPTM back connection.

Level Models Accuracy: ±2% for the first and last quarters of the scale,

the middle half of scale is ±1%.

Specifications

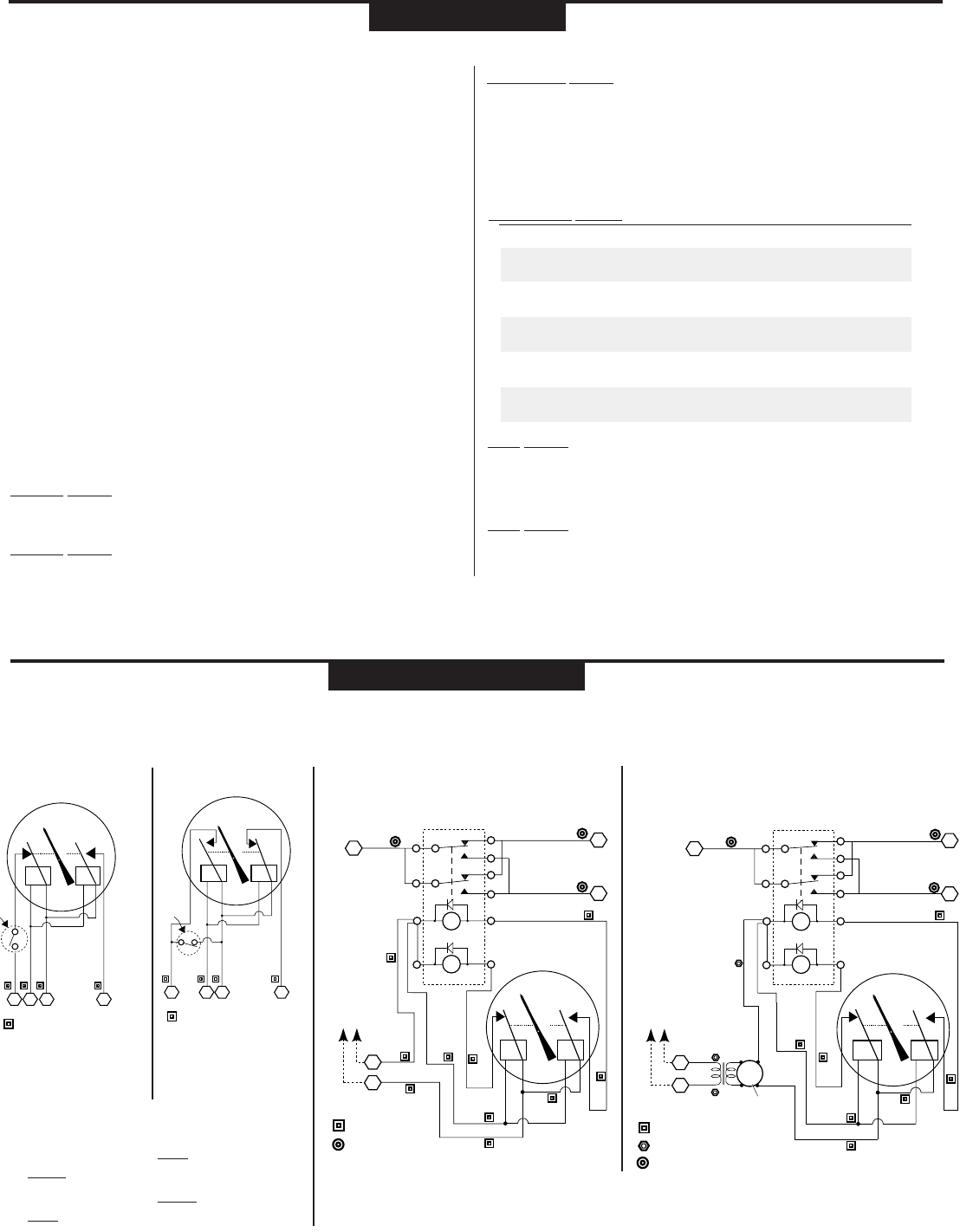

Internal Wiring

Temperature Models Accuracy

-60 to 60°F ± 2°F ± 2°F ± 2°F

(-51 to 16°C) (± 1°C) (± 1°C) (± 1°C)

-40 to 136°F ± 4°F ± 2°F ± 2°F

(-40 to 58°C) (± 2°C) (± 1°C) (± 1°C)

15 to 250°F ± 8°F ± 2°F ± 2°F

(9 to 121°C) (± 4°C) (± 1°C) (± 1°C)

130 to 350°F ± 8°F ± 2°F ± 3°F

(60 to 180°C) (± 4°C) (± 1°C) (± 1.5°C)

260 to 450°F ± 8°F ± 2°F ± 3°F

(127 to 232°C) (± 4°C) (± 1°C) (± 1.5°C)

Temperature Range Lower

1

/4 Middle

1

/2 Upper

1

/4

3

1

Note 1

White

Red

Green

Black

24

+

–

+

–

Low

High

= 26 AWG (0.12 mm

2

)

Red= Positive Power Input

Green= Negative Power Input

White= Low Transistor Sinking Output

Black= High Transistor Sinking Output

Customer

Connections

12 or 24 VDC

7

9

6

A

5

B

8

3

4

1

Red

White

Red

Red

= 16 AWG (1.5 mm

2

)

= 26 AWG (0.12 mm

2

)

Brown

Relay Coils

Yellow

Blue

Green

Green

Black

Black

1

2

4

5

3

Green

Red

+

--

++

––

Set

Reset

Low

High

Contacts Shown Reset

(Low Limit has been Met)

45PHE, 45THE and

45LHE Series

Customer

Connections

120 VAC

7

9

6

8

3

4

1

Red

White

White

Black

Full Wave

Rectifier

Low

High

Contacts Shown Reset

(Low Limit has been Met)

= 18 AWG (1.0 mm

2

)

Brown

Yellow

Blue

Green

Black

Black

1

2

4

5

3

Green

Red

Red

= 16 AWG (1.5 mm

2

)

= 26 AWG (0.12 mm

2

)

+

–

+

–

N

H

7

9

A

5

B

4

1

Relay Coils

Set

Reset

312 4

Note 2

White

Red

Green

Black

+

–

+

–

Low

High

= 26 AWG (0.12 mm

2

)

Red= Positive Power Input

Green= Negative Power Input

White= Low Transistor Sinking Output

Black= High Transistor Sinking Output

45PHENC, 45THENC

and 45LHENC Series

45PHEBP, 45THEBP and

45LHEBP Series (12/24 VDC)

Hall Effect Sensors Ratings: 300 mA continuous

45PHEBP, 45THEBP and

45LHEBP Series (120 VAC)

Note 1: Start/Run Switch; Open for Start,

Closed for Run (surface mount models only).

Note 2: Start/Run Switch; Closed for Start,

Open for Run (surface mount models only).

Latching Relay Contact Ratings: SPDT Dry Relay Contacts, 10 A @ 120 VAC

Important information: When using the 45HE SWICHGAGE

®

with inductive loads, we recommend installing a suppression diode across all coil(s).