L-94071N page 2 of 2

INSTALLATION

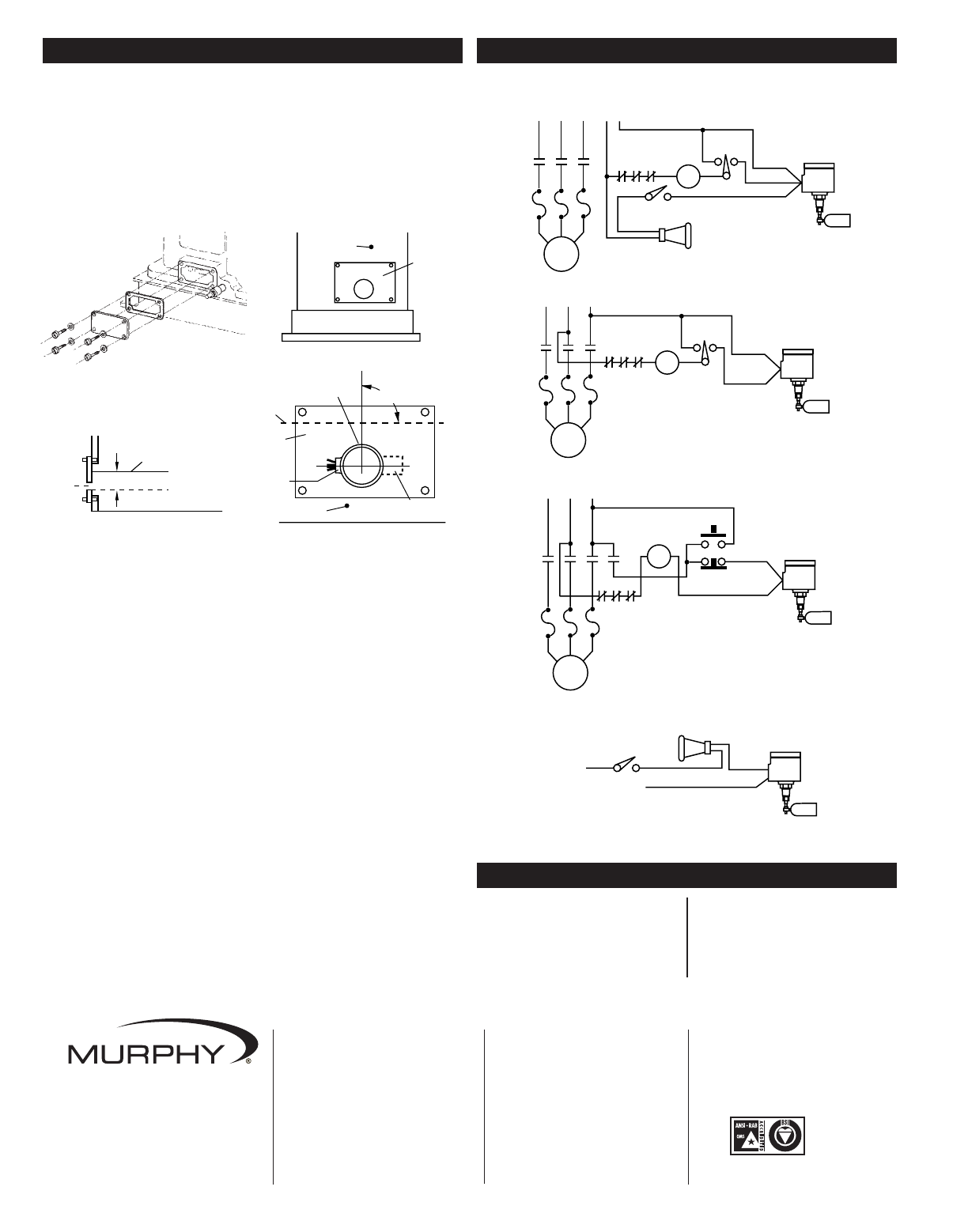

Compressors With Inspection Plate

1. Drain crankcase.

2. Remove crankcase inspection plate (Figure 1).

3. Drill and tap a 1/2 NPT female pipe thread into the inspection plate at

point “A” (Figure 2). CAUTION: Clean area of metal shavings. The

hole is to be a minimum of 2 in. (51 mm) below normal running oil

level (Figure 3).

4. Unscrew and remove float on the L971 switch.

5. Apply pipe dope to the process connection threads.

6. Thread the L971 switch into crankcase hole until “TOP” label is up (Figure

4). Be sure the float moves freely and there are no obstructions.

7. If adjustment of shutdown level is required, loosen hex set screw on float

attachment. Rotate float attachment to desired level. Retighten set screw.

8. Replace float and reinstall inspection plate and gasket in original position.

9. Install drain plug.

10. Wire accordingly.

11. Fill crankcase to proper level.

Compressors Without Inspection Plate

1. If installing into a thick wall crankcase, drill and tap a 1/2 NPT

female pipe thread into the crankcase. CAUTION: Clean area of

metal shavings. The hole is to be a minimum of 2 in. (51 mm) below

normal running oil level (Figure 3).

If installing into a thin wall crankcase, drill a hole in the crankcase

slightly larger than outside diameter of a 1/2 in. coupling. The hole is to

be a minimum of 2 in. (51 mm) below normal running oil level (Figure

3). CAUTION: Clean area of metal shavings. Weld a half collar (1/2

NPT) into the hole.

2. Follow steps 4 thru 11 above.

Normal

Oil Level

Hole

2 in. (51 mm) Minimum

Inspection

Plate

Crankcase

A

Oil Level

Crankcase

Float

90°

“TOP” Label

Inspection

Plate

Conduit

Figure 1

Figure 4

Figure 2

Figure 3

Shutdown Circuit for H.O.A. Operation

H

O

A

HC

Yellow

Black

Line Voltage

Shutdown and Alarm Circuit

Control Voltage

H

O

A

HC

Crankcase

Switch

Crankcase

Switch

Crankcase

Switch

Crankcase

Switch

Alarm Silencer

Alarm

Yellow

Black

Red

Alarm Without Shutdown Circuit

Power Supply

Alarm Silencer

Alarm

Yellow

Red

Shutdown Circuit for Start-Stop Push-button Operation

HC

Yellow

Start

Stop

Black

TYPICAL WIRING

REPLACEMENT PARTS

Description Part Number

Cover 15050443

Cover Gasket 15050369

Snap-switch 00002326

Description Part Number

Float

Polyurethane 15050679

Stainless Steel 15050356

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax+1 281 633 4588

e-mailsales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mailventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax+44 1722 410088

e-mailsales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax+1 661 947 7570

e-mailsales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax+61 3 9358 5558

e-mailmurphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.