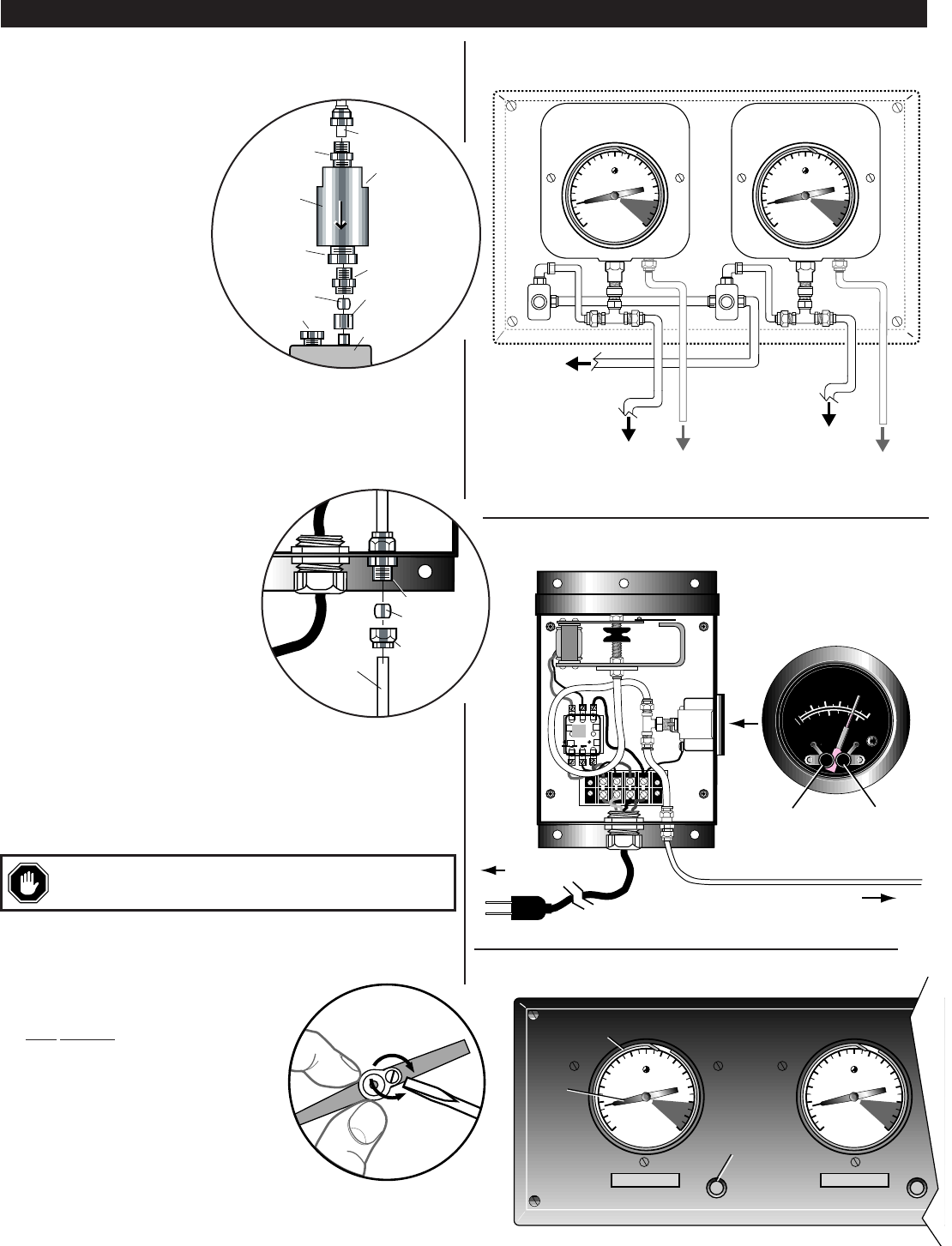

Installing the CKBO Check Valve

The optional CKBO check valve is designed

to prevent product from backing up into the

gage(s). We recommend installing the

CKBO valve at top of the tank plug as

follows (refer to Detail C):

1.

Determine a location for the valve.

Use of sealant on all fitting

threads is strongly suggested.

2.

Attach CKBO to the tank plug

using wrench on valve flats.

See markings on the valve body

for positioning.

3.

Attach tubing to CKBO as shown.

Securely tighten all fittings.

All connections must be air tight.

Installing the SMPA/SMPA230 Pump Assembly

The pump assembly should be installed near the SM or SMVR panel.

Connect the pump as follows (refer to Fig. 3 and 4 also see Detail D):

1.

Before connecting the tubing from the SM or

SMVR panel to the pump assembly, make sure

the tubing reaches the pump assembly

sensor fitting.

2.

Connect the end of the tubing to the sen-

sor fitting as shown at right (Detail D).

Tubing should be continuous length

without splices.

3.

The pump assembly includes a power

cable, 16 AWG (1.5 mm

2

), 8 ft. (2.4 m)

long. Connect the cable to 120 VAC or

230 VAC power source.

The pump assembly has a pressure SWICHGAGE

®

with low and high pressure set points. When the gage pointer reaches the

low pressure set point, the pump starts to built up purge pressure. When the

pointer reaches the high set point, sufficient volume is reached stopping the

pump. The set points are factory pre-set for your convenience.

Resetting the Pointer

After the SM/SMVR complete system has been connected, reset the pointer

for proper level indication, proceed as follows

(see Fig. 5 and Detail E):

1.

Determine actual product level by any reliable

means and record this value.

2.

Very carefully remove the retaining ring

guarding against its spring-action, it can

cause injuries. Remove the lens also.

3.

Carefully hold the pointer, as shown at

right, making sure not to bend it.

4.

With a small screwdriver, turn the setting

screw to corresponding stick reading value

recorded in step 1.

Clockwise to raise the pointer — counter clockwise to lower the pointer.

5.

Replace the lens and snap ring.

INSTALLATION

Continued

3

To Tank 1 Plug

Sensor Fitting

To Tank 2 Plug

Sensor Fitting

SM Panel (SM2 Model Shown)

To Tank 1 Plug

Vapor Recovery

Fitting

To Tank 2 Plug

Vapor Recovery

Fitting

To Pump

Assembly

FEET

MURPHY

LEVELGAGE

FEET

MURPHY

LEVELGAGE

120 VAC or 230 VAC

Tubing to SM Panel

Pressure SWICHGAGE

®

kPa

PRESSURE

0

100

20

40

60

0

300

80

600

PSI

M

U

R

P

H

Y

S

W

I

C

H

G

A

G

E

®

Low trip point

adjustment

High trip point

adjustment

Fig. 4

Pump Assembly

Tubing

Power

Cable

Compression

Nut

Ferrule

Sensor Fitting

Pump

Panel

Detail D

Read Button

SM Panel (SM2 Model Shown)

FEET

MURPHY

LEVELGAGE

FEET

MURPHY

LEVELGAGE

Pointer

Snap Ring

UNLEADED UNLEADED

Turn to Lower

the Pointer

Turn to Raise

the Pointer

CAUTION:

SM and SMVR models are precalibrated in feet of

static pressure above gage connection. Pointer MUST be reset to zero.

Detail E

Tubing

Check

Valve

Valve

Flat

1/4 NPTM

straight

fitting

1/4 NPTM

straight fitting

Ferrule

Ferrule nut

1/2 NPTM to

1/4 NPTF

Reducer

UTKN Tank Plug

or tank top

Hole Plug

T

A

N

K

Detail C

Fig. 3

SM Panel Tubing Configuration

(SM2 Model shown)

Fig. 5