5

English

CAUTION

• Do not use bleach, chlorine, alcohol, or aromatic-based solutions,

moisturizing or antibacterial soaps, or scented oils to clean any of the mask

components. These solutions may cause damage and reduce the life of the

product.

• Do not expose any part of the mask system or tubing to direct sunlight as it

may cause the product to deteriorate.

• The headgear is sensitive to heat and must not be ironed.

• If any visible deterioration of a mask component is apparent (cracking,

crazing, tears, etc), the mask component should be discarded and replaced.

Cleaning the Mask between Patients

All mask components can be disinfected/sterilized using validated procedures.

The following table presents a summary of the validated procedures for

disinfection/sterilization of the system. Refer to the website

www.resmed.com/masks/sterilization/americas for details.

To clean the headgear between patients use the method described in the

previous section “Cleaning the Mask in the Home”.

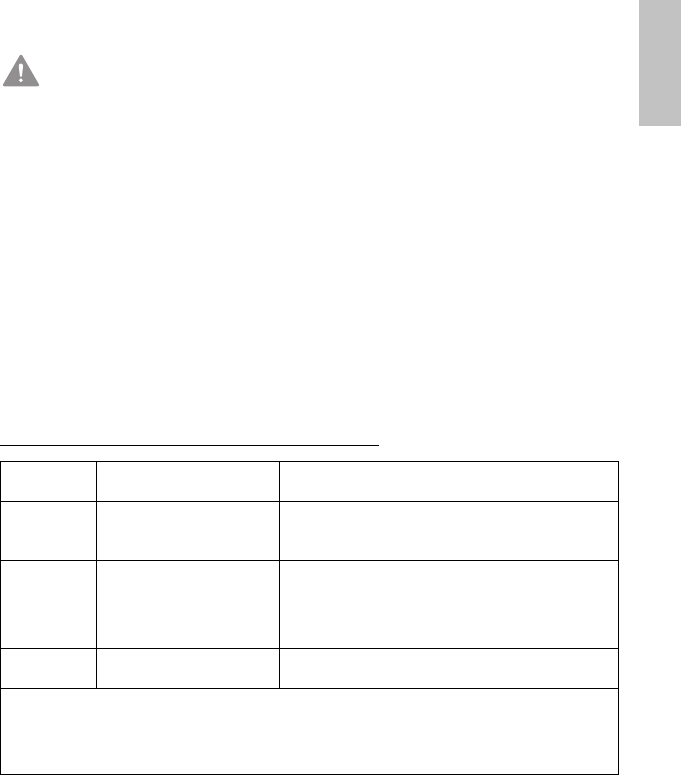

Methods Pre-disinfection/

sterilization

Disinfection/Sterilization

Chemical Detergent

eg, Alconox

™

Solution (any one)

• Ortho-phthalaldehyde 0.55% (eg, CIDEX

™

OPA)

• Glutaraldehyde 3.4% (eg, CIDEX Plus

™

)

Thermal Detergent

eg, Alconox

Temperature-time (any one)

• 158°F (70°C) for 100 minutes

• 167°F (75°C)for 30 minutes

• 176°F (80°C) for 10 minutes

• 194°F (90°C) for 1 minute

STERRAD

™

Detergent

eg, Alconox

System

STERRAD Sterilization System

Notes:

• Testing by ResMed has shown that the components can withstand 15 cycles of

disinfection/sterilization for the methods listed in the table.

• When using detergents, disinfectants or sterilization agents, always follow the

manufacturer’s instructions.

608140r2.book Page 5 Thursday, November 2, 2006 9:37 AM