1

ConneXium Ethernet Gateway

TSXETG100

Installation Guide

63230-319-221A1 10/2009

SAFETY PRECAUTIONS

INTRODUCTION

Box Contents

• ETG unit and connectors

• Registration card

• Installation guide

• Technical Library CD-ROM

• Technical support contact sheet

Additional Resources

Documentation and Firmware: Go to www.schneider-electric.com.

Quick Start Checklist

❏ Mount the unit.

❏ Determine the control power method and connect the power.

❏ Configure the Ethernet communications settings with a web browser (using an Ethernet crossover

cable) or with HyperTerminal (using a null modem cable, which is included in the TCSEAK0100

configuration kit [sold separately]).

❏ Configure the serial ports.

❏ Configure the device list.

❏ Wire the serial ports.

CLASS I, DIVISION 2 COMPLIANT INSTALLATION

REQUIREMENTS AND WARNINGS

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, and D or non-hazardous locations

only.

All terminal strip screws must be tightened to a torque of 5-7 in/lb (0.56 - 0.79 Nm)

Sealed Relay Device information includes:

• Sealed Device: Relay

• Manufacture of Plastic Material: Ticona

• Designation of Plastic Material: H140, E130I, T840 or T130

• Generic Name of Plastic Material: Liquid Crystal Polymer (LCP)

It is recommended that the sealed relay device be inspected periodically to check for degradation of the

materials and to replace the complete product, not the sealed deivce if any degradation is found.

Field conductors need to be suitable for use in a 70°C temperature ambient and “USE COPPER

CONDUCTOR ONLY”.

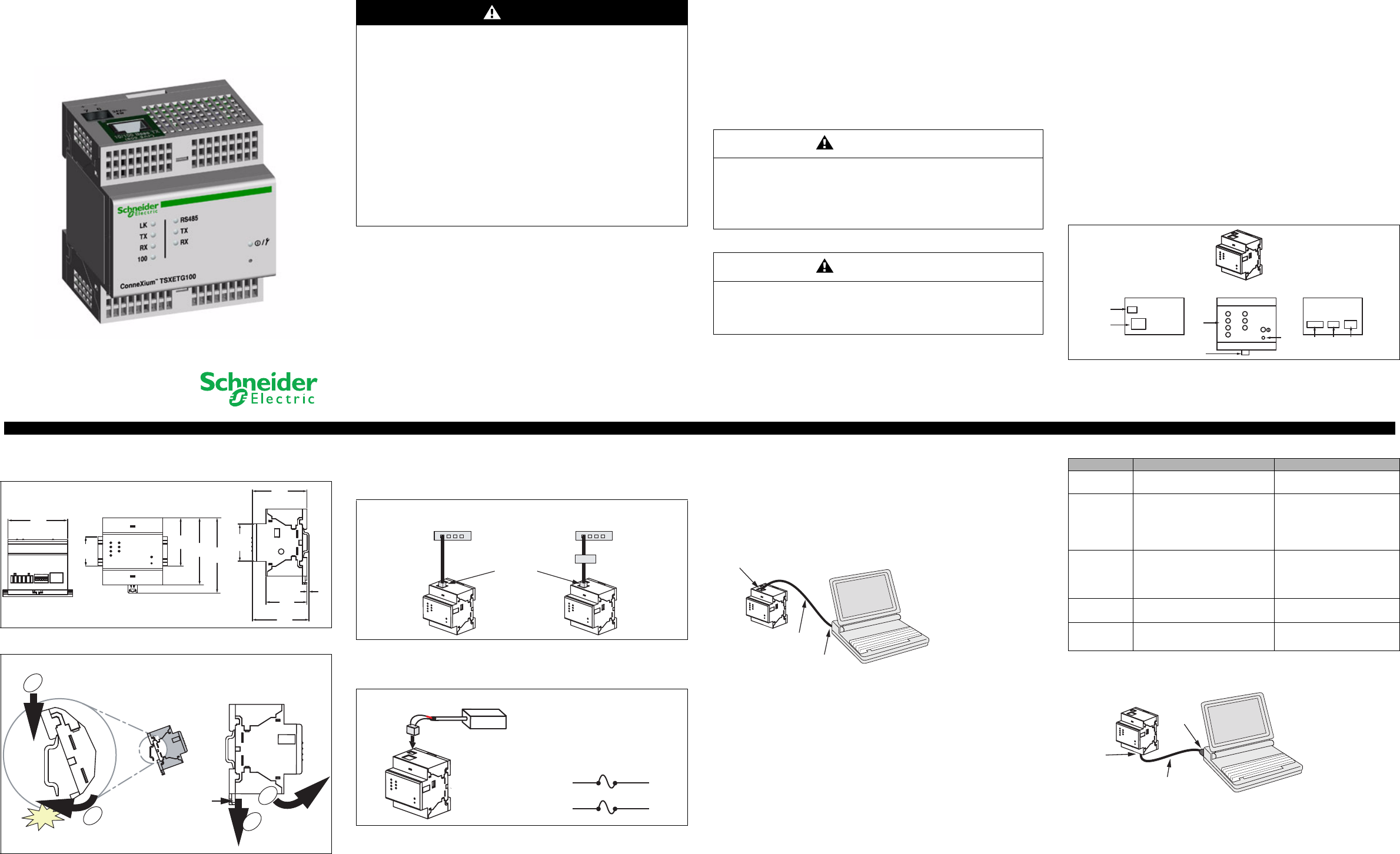

DESCRIPTION

1. 24 Vdc control power connection

2. 10/100BaseTx (802.3af) connection

3. LEDs:

Ethernet:

• LK: Active link

• TX: Transmitting data

• RX: Receiving data

• 100: Link speed. 100 Mb = ON, 10 Mb = OFF

Serial:

• RS485: RS485 mode = ON, RS232 mode = OFF

• TX: Transmitting data

• RX: Receiving data

Power/Status

4. DIN rail release

5. Reset button (press to reboot the ETG; no data is lost)

6. RS485 connection

7. Dip switches

8. RS232 connection

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Only qualified workers should install this equipment. Such work should be performed only after

reading this entire set of instructions.

• NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this equipment, disconnect all

sources of electric power. Assume that all circuits are live until they have been completely de-

energized, tested, and tagged. Pay particular attention to the design of the power system. Consider

all sources of power, including the possibility of backfeeding.

• Be sure to follow instructions for Class I, Division 2 environment. Refer to the “Class I, Division 2

Compliant Installation Requirements and Warnings” section.

• Apply appropriate personal protective equipment (PPE) and follow safe electrical practices. For

example, in the USA, see NFPA 70E.

• Turn off all power supplying the equipment in which the ETG is to be installed before installing and

wiring the ETG.

• Always use a properly rated voltage sensing device to confirm that power is off.

• Beware of potential hazards, wear personal protective equipment, and carefully inspect the work

area for tools and objects that may have been left inside the equipment.

• The successful operation of this equipment depends upon proper handling, installation, and

operation. Neglecting fundamental installation requirements may lead to personal injury as well as

damage to electrical equipment or other property.

Failure to follow these instructions will result in death or serious injury.

WARNING

EXPLOSION HAZARD

• Substitution of any components can impair suitabiity for Class I, Division 2.

• Do not disconnect while the circuit is live or unless the area is known to be free of ignitable

concentrations.

Failure to follow this instruction can cause death or serious injury.

WARNING

POTENTIAL EQUIPMENT DAMAGE

Exposure to some solvents can degrade the sealing properties of materials used in this Gateway.

Failure to follow this instruction can cause equipment damage.

1

2

678

3

4

LK

TX

RX

100

RS485

TX

RX

5

/

TOP FRONT BOTTOM

INSTALLATION

Dimensions

DIN Rail Mounting and Removal

Powering the ETG

Power-over-Ethernet (PoE [IEEE 802.3af])

The ETG supports PoE (IEEE 802.3af), allowing the ETG to be powered over an Ethernet connection. Use

either configuration A or B below:

NOTE: Use a PoE injector that fully complies with the IEEE 802.3af standard for active midspan devices,

such as the TCSEAV0100 from Schneider Electric.

24Vdc Control Power

NOTE: For Class I, Division 2 installations, tighten the terminal strip screws to a torque of 5-7 in/lb

(0.56 - 0.79 Nm).

Ethernet Configuration

Before configuring the ETG, obtain a unique static IP address, subnet mask, and default gateway address

from your network administrator. Use a Web browser or HyperTerminal to configure the ETG with the

information obtained from your network administrator.

Ethernet Setup Using a Web Browser

1. Disconnect your computer from your network.

NOTE: After disconnecting from your network, your computer should automatically use the default IP

address 169.254.###.### (### = 0 to 255) and the default subnet mask 255.255.0.0. If the IP address

is not automatically configured, contact your network administrator to set up a static IP address.

2. Connect an Ethernet crossover cable from the ETG to the computer.

NOTE: See “Powering the ETG” for powering options.

3. Start Internet Explorer (version 6.0 or higher).

4. In the Address text box, type 169.254.0.10, then press Enter.

5. Type Administrator for your user name, type Gateway for your password, then click OK. User names

and passwords are case sensitive.

6. Click Setup.

7. If the “Ethernet & TCP/IP” page isn’t open, click Ethernet & TCP/IP in the menu on the left side of the

page.

8. Select the frame format and media type (see Table 1 for a description of each option).

9. Enter your IP address, subnet mask, and default gateway address assigned to your ETG by your

network administrator (see Table 1 for a description of each option), then click Apply.

10.Reconnect your computer to your network. If you assigned a static IP address to your computer in step

1, you must restore your computer’s original settings before reconnecting to your network.

Ethernet Setup Using HyperTerminal

1. Attach a null modem cable (see below).

NOTE: The RJ45 to DB9 adapter and the Ethernet crossover cable are included in the TCSEAK0100

configuration kit (sold separately).

2. Click Start > Run, then type hypertrm.

3. In the Name text box, type a name for the new connection (for example, ETG config), then click OK.

4. In the Connect using drop-down list box, select the computer COM port you will be using, then

click OK.

35

1.38

57.9

2.28

80.8

3.18

90.7

3.57

65.8

2.59

45.2

1.78

2.5

0.10

49.5

1.95

68.3

2.69

72

2.83

Millimeters

Inches

1

2

Click

1

2

DIN Rail

(TS-35)

Slide release

Mount Removal

AB

Midspan PoE Injector

(part number TCSEAV0100)

10/100BaseTx

Ethernet Switch with

endspan PoE ports

Ethernet Switch

+

–

(7) +

(6) –

ETG Control

Power

Connector

Power Supply

+24 Vdc ± 10%

24 Vdc

Power

Source

Fuse

disconnect

Ethernet

crossover

cable

10/100BaseTx

(802.3af) port

To computer

Ethernet port

Table 1: ETG Ethernet and TCP/IP Settings

Option Description Setting

Frame Format

Used to select the format for data sent over

an Ethernet connection.

Ethernet II, 802.3 SNAP

Default: Ethernet II

Media Type

Used to define the physical Ethernet

connection.

• 10T/100Tx Auto

• 10BaseT-HD

• 10BaseT-FD

• 100BaseTX-HD

• 100BaseTX-FD

Default: 10T/100Tx Auto

IP Address

Used to enter the static IP address of the

ETG.

NOTE: If you enter an IP address that is

already in use, you will be prompted to

select a different IP address.

0.0.0.0 to 255.255.255.255

Default: 169.254.0.10

Subnet Mask

Used to enter the Ethernet IP subnet mask

address of your network.

0.0.0.0 to 255.255.255.255

Default: 255.255.0.0

Default Gateway

Used to enter the gateway (router) IP

address used for wide area network (WAN)

communications.

0.0.0.0 to 255.255.255.255

Default: 0.0.0.0

RS232 serial

port

(See Table 3

on page 2

for pinouts)

RJ45 to

DB9

adapter

Ethernet

crossover

cable