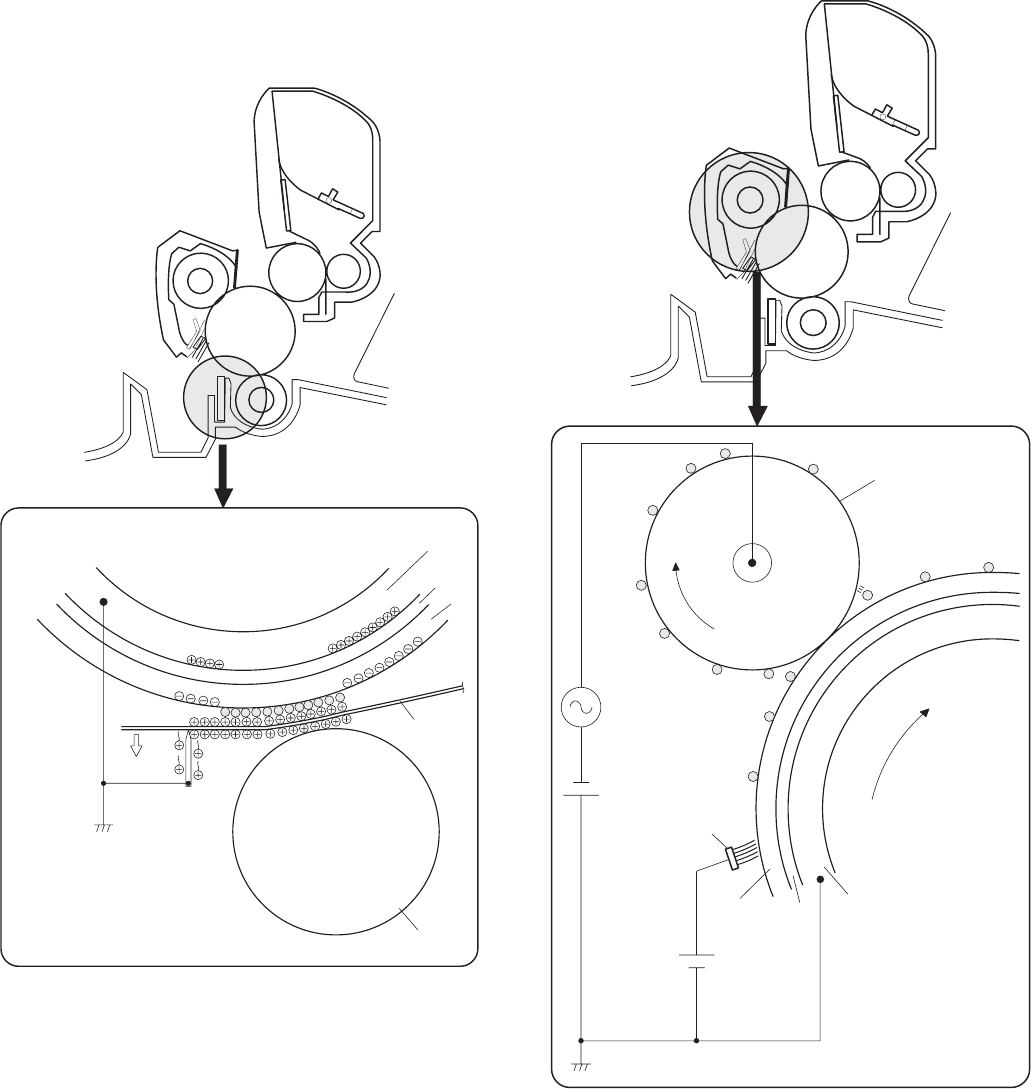

The positive charges are attracted to the OPC drum which is nega-

tively charged, and put on the paper transported between the transfer

roller and the OPC drum. The paper, therefore, is charged positively.

The negative charged toner on the OPC drum is attracted to the

paper which is positively charged and visible images of toner are

transferred onto the paper.

In the cleaning mode, a voltage of –850 V is applied. If there is toner

on the transfer roller, the toner is attracted to the OPC drum.

Step 5 (Paper separation): Paper is separated from the OPC drum.

An electric force is acting between the paper which is positively

charged in the transfer process and the OPC drum which is negative-

ly charged. Positive charges on the paper are moved to the aluminum

layer through the separation electrode to reduce the potential dif-

ference between the OPC drum and the paper.

By this operation, the paper can be easily separated from the OPC

drum.

Step 6 (Discharging): The drum surface is discharged by the dis-

charge brush to facilitate cleaning. (Residual

toner can be easily collected by the main

charger roller.)

Step 7 (Cleaning): Residual toner on the OPC drum is removed.

The main charger brush is of roller shape and is rotating.

The main charger brush stirs residual toner and paper dust on the

OPC drum. The residual toner and paper dust are evenly distributed

and put on the OPC drum again to be sent to the developing roller.

CGL

CTL

Aluminum layer

(Drum base)

Paper

Separation

electrode

Transfer roller

AC600V

(P-P)

CTL

CGL

DC-850V

DC+500V

Main charger brush

Residual toner

Discharge brush

OPC drum

Aluminum layer

(Drum base)

1 – 23