SVL-A, SVL-B, SVL-C, & SVL-D Self-Contained Material Loaders - Venturi Style 34 of 49

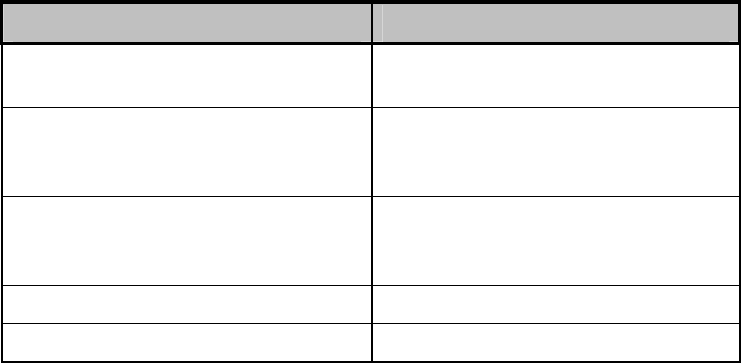

5-4 Troubleshooting

PROBLEM REMEDY (See Test Steps Below)

The unit is not conveying and is not

active.

A, B, G, H

The unit is not conveying; the

compressed air valve is activated

when the device is switched on.

C, D, E, F, N

The unit is not conveying; the

compressed air is flowing through

the valve.

C, D, E, F, I, J, K,N

The unit is overfilled. G, L, M

The unit is not filling properly. C, D, E, F, I, J, K, L,N

Test steps:

A - Make sure the unit is switched ON.

B - Make sure the unit is plugged in and the proper voltage is present.

C - Make sure sufficient compressed air is available 70-90 psi (5-6 bar).

D - Make sure the venturi assembly is inserted in the material.

E - Make sure the compressed air hose is properly connected to the venturi assembly.

F - Make sure the compressed air hose (incoming supply line) is properly connected to

the control solenoid.

G - Make sure the level sensor is properly adjusted.

H - Make sure the cable of the level sensor is properly connected.

I - Make sure the filter is not clogged.

J - Make sure the screen is not clogged.

K - Make sure the vinyl flexible hose is properly connected.

L - Make sure the compressed air supply is properly adjusted.

M - Make sure the level sensor is not defective.

N - Check source of material.