3. MAINTENANCE

EO1-33030

3.2 Care/Handling of the Media

3- 2

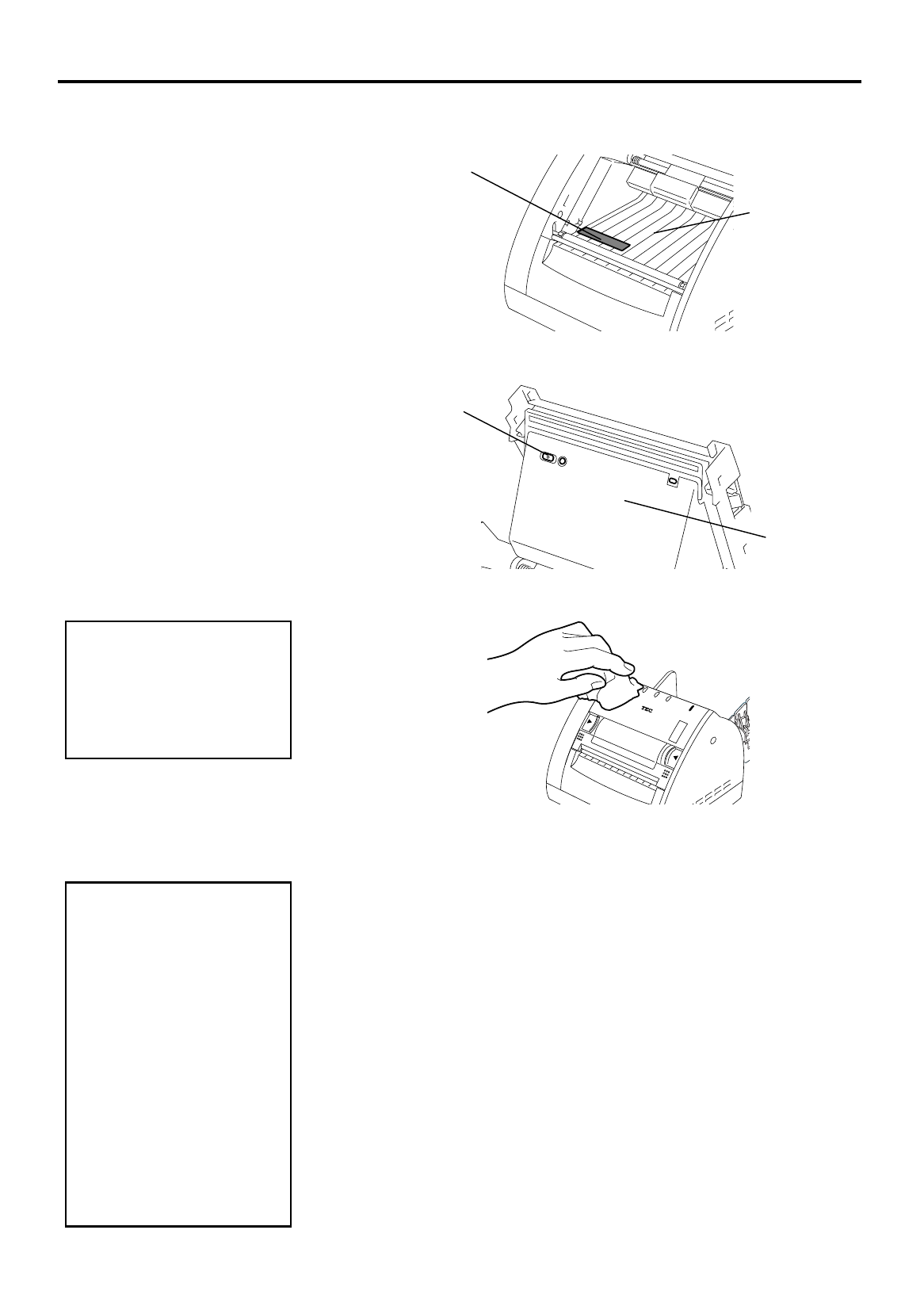

3.1.2 Paper Path/Sensors

3.1.3 Covers

3.2 Care/Handling of the

Media

1.

Wipe the Paper Path and Sensor Window with a dry soft cloth.

2.

Remove dust from the Media Sensor with a brush or equivalent.

Wipe the Cover with a dry soft cloth. Wipe off dirt with a soft cloth

slightly moistened with water.

• Do not store the media for longer than the manufacturer’s

recommended shelf life.

• Store media rolls on the flat end. Do not store them on the curved sides

as this might flatten that side causing erratic media advance and poor

print quality.

• Store the media in plastic bags and always reseal after opening.

Unprotected media can get dirty and the extra abrasion from the dust

and dirt particles will shorten the print head life.

• Store the media in a cool, dry place. Avoid areas where they would be

exposed to direct sunlight, high temperature, high humidity, dust or gas.

• The thermal paper used for direct thermal printing must not have

specifications which exceed Na

+

800 ppm, K

+

250 ppm and Cl

-

500

ppm.

• Some ink used on pre-printed media may contain ingredients which

shorten the print head’s product life. Do not use labels pre-printed with

ink which contain hard substances such as carbonic calcium (CaCO

3

) or

kaolin (Al

2

O

3

, 2SiO

2

, 2H

2

O).

For further information, please contact your local distributor or your

media manufacturers.

CAUTION!

Do not use any volatile

solvent including thinner

and benzene, as this may

cause discoloration or

distortion of the cover.

CAUTION!

Be sure to read carefully

and understand the Supply

Manual. Use only media

which meet specified

requirements. Use of non-

specified media may

shorten the head life and

result in problems with bar

code readability or print

q

uality. All media should

be handled with care to

avoid any damage to the

media or printer. Read the

g

uideline in this section

carefully.

Sensor Window

Paper Path

Media Sensor

Paper Path