Meets or Exceeds

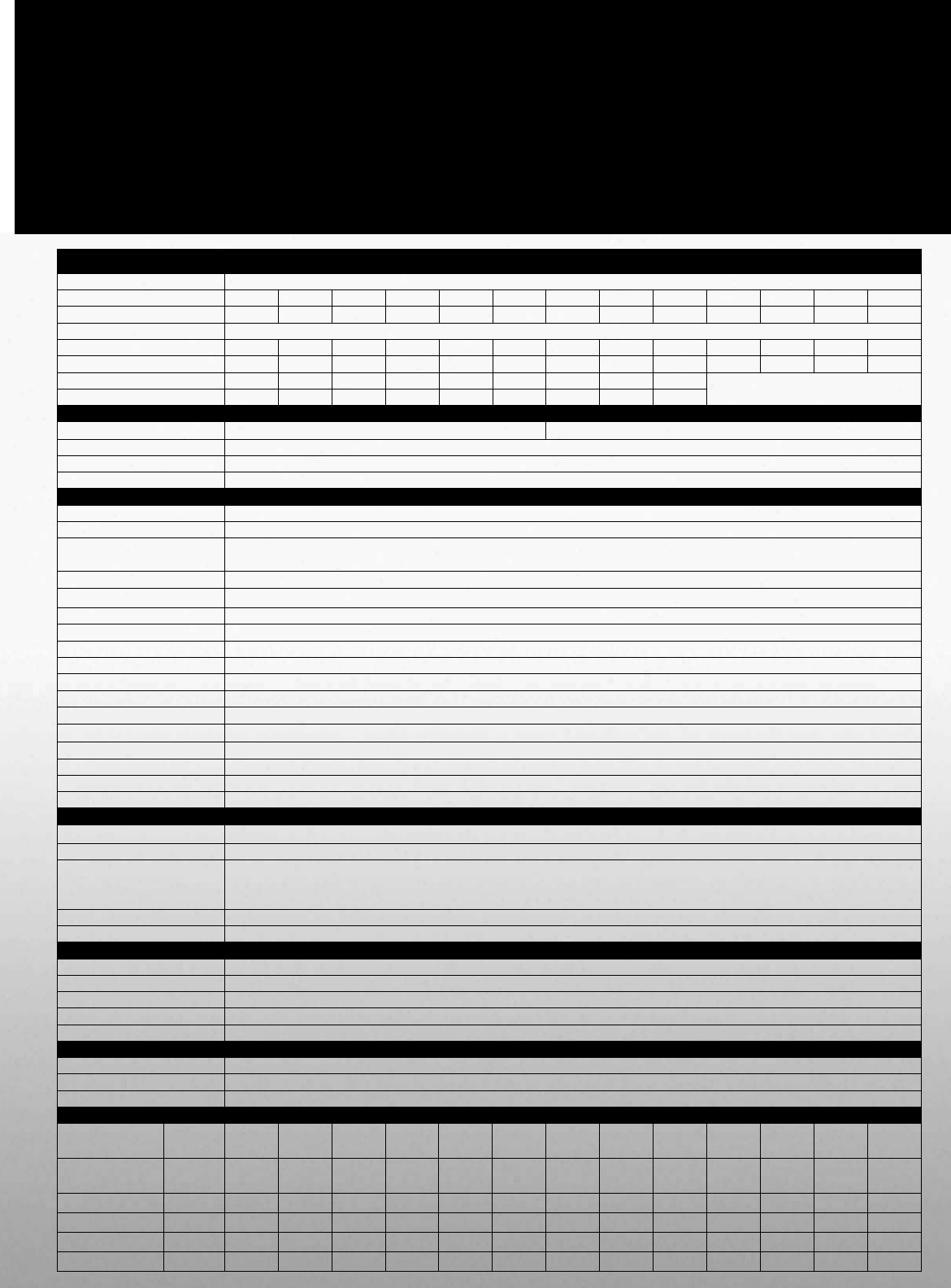

Q9 Standard Specications

Input Voltage 230 V

HP Rating 1 2 3 5 7.5 10 15 20 25 30 40 50 60

Current Rating 4.8 7.8 11 17.5 25.3 32.2 48.3 62.1 78.2 92 120 150 177

Input Voltage 460 V, 50/60 Hz, Three-Phase

HP Rating 1 2 3 5 7.5 10 15 20 25 30 40 50 60

Current Rating 2.1 3.4 4.8 7.6 11 14 21 27 34 40 52 65 77

HP Rating 75 100 125 150 200 250 300 350 400

Current Rating 96 124 156 180 240 302 361 414 477

Power Requirements

Input Voltage Range 200 to 240 V, 50/60 Hz, Three-Phase 380 to 480 V, 50/60 Hz, Three-Phase

Power Terminals Input (L1/R, L2/S, L3/T), Output (T1/U, T2/V, T3/W), DCL (PO, PA), DC Bus (PA, PC)

Voltage Tolerance ±10%

Frequency Tolerance ±2%

Control Specications

Output Method Sine Wave Pulse-Width Modulated System

Output Frequency Range 0 to 299 Hz

V/Hz Pattern

Constant Torque, Variable Torque, Automatic Torque Boost, Sensor-Less Vector Control (Speed), V/f Five-Point Setting,

Permanent Magnet Control, Auto Power-Saver

Overload Current Rating 100% Continuous; 110% for One Minute

Frequency Control Rotary Encoder Integrated Into EOI, 0 to 10 VDC, ±10 VDC, 4 to 20 mA, Binary Input, Motor Operated Potentiometer

Frequency Accuracy Analog Input: ±0.2% of Maximum Output Frequency; Digital Input: ±0.01% of ±0.022 Hz of Output Frequency

Frequency Resolution Operation Panel: 0.01 Hz

Acceleration/Deceleration 0.1 to 6000 Seconds

Analog Inputs Three: One Isolated Input Selectable Between 0 to 10 VDC/4 to 20 mA, One 0 to 10 VDC, and One ±10 VDC

Analog Outputs Two Programmable to 57 Functions (One Switchable 0 to 10 VDC/0 to 20 mA, and One 0 to 1 mA)

Discrete Inputs Eight Programmable to 41 Functions

Sink/Source Switching Ability to Switch Between Sink Logic and Source Logic

Discrete Outputs Three Programmable to 83 Functions (Two Form-A and One Form-C); Outputs Rated at 2 A/120 VAC, 2 A/30 VDC

PID (Set Point Control) Adjustment of Proportional Gain, Integral Time, Differential Time, and Delay Filter

Braking Control DC Braking, Over-Flux Braking

Communication Ports Two-Wire/Four-Wire RS485

Communication Protocol BACNet

®

, LonWorks

®

, Metasys N2

®

, Modbus RTU

®

, APOGEE FLN

®

Protection

Protective Functions Overvoltage Stall, Overcurrent Stall, Critical (Skip) Frequencies, Ride-Through, Electronic Thermal Motor Protection

Interrupting Current Rating 100,000 AIC

Faults

Overcurrent, ASD Overheat, ASD Overload, Motor Overload, Overvoltage, Overtorque, Undercurrent, Ground Fault,

Communication Time-Out, Analog-Input Terminal Overvoltage, Emergency Stop, Input/Output Phase Loss, RAM/ROM

Error, Undervoltage

Retry Ability to Reset Certain Faults Automatically; Programmable Up to 10 Retries

Restart Ability to Detect Speed and Direction of Freewheeling Motor and Start into Motor Smoothly

Interface

EOI Display Full-English Backlit LCD Display

Keys LOCAL/REMOTE, ESC, RUN, MODE, STOP/RESET

Rotary Encoder Encoder with Integrated Enter Key for Frequency and Parameter Adjustments

Monitoring Monitors 19 Drive Conditions

Display Units Programmed to Display Percentage or Volts/Amps

Ambient Conditions

Temperature -10˚ to 40˚C

Relative Humidity Maximum 93% (Non-Condensing)

Altitude 1000 Meters or Less

Q9 Dimensions

230 V 1 to 2 HP

3 to

5 HP

7.5 HP 10 HP

15 to

20 HP

25 to

30 HP

-

40 to

60 HP

- 100 HP 125 HP - - -

460 V 1 to 3 HP

5 to

7.5 HP

10 HP

15 to

20 HP

25 to

30 HP

40 HP

50 to

60 HP

-

75 to

125 HP

150 HP 200 HP 250 HP

300 to

350 HP

400 HP

Frame 2 3 4 5A 5B 6 7A 7B 8 9B 10B 11B 12B 13A

Height (in.) 10.0 11.1 12.6 12.6 15.7 16.5 21.7 21.7 24.8 36.2 40.2 46.9 46.9 46.9

Width (in.) 5.1 6.1 6.9 8.3 9.1 9.4 9.4 12.6 12.6 12.2 13.8 13.0 16.9 23.0

Depth (in.) 6.0 6.5 6.5 7.5 7.5 8.3 8.3 9.5 11.4 14.6 14.6 14.6 14.6 14.6

Your Specifications