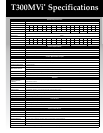

T300MVi Specifications

Standard Specications

Item

Voltage Class 4160 V

Drive Rating (A): 62 74 87 99 112 124 155 186 217 248 279 310 372 434 496 558 620

4160 Drive Output (kVA): 447 536 625 715 804 893 1116 1340 1563 1786 2010 2233 2680 3126 3573 4019 4466

Nominal HP 4160 V** 500 600 700 800 900 1000 1250 1500 1750 2000* 2250 2500 3000 3500 4000 4500 5000

Dimensions H x W x D (in) 104 x 74 x 44 104 x 122 x 44 104 x 1 64 x 50 104 x 174 x 50 104 x 222 x 50

Voltage Class 2400 V

Drive Rating (A): 64 75 86 97 107 129 150 172 193 215 269 322 376 430 504 537

2400 V Drive Output (kVA): 268 313 357 402 447 536 625 715 804 893 1116 1340 1563 1786 2010 2233

Nominal HP 2400 V** 300 350 400 450 500 600 700 800 900 1000 1250 1500 1750 2000 2250 2500

Dimensions H x W x D (in) 104 x 74 x 44 104 x 122 x 44 104 x 174 x 50 104 x 222 x 50

Power Requirements

Output Frequency (Hz) 0 to 120 Hz

Main Circuit Three-Phase 4160 V Input Isolation Transformer 24-Pulse Design with Input-Fused Disconnect and Vacuum Contactor, IGBT Output

Control Circuit Integral to Main Transformer; Includes 120 V and 460 V

Tolerance Voltage: ± 10%; Frequency ± 5%

Control Specications Input

Control Method Multi-Level Pulse Width Modulated (PWM) Output Control

Frequency Precision Analong Input: ± 0.5% of Maximum Output Frequency; Digital Input: 0.01%

V/F Control V/Hz, Sensorless Vector Control, Variable Torque, Closed-Loop Vector Control, Constant Torque (Option)

Acceleration/Deceleration 0.1 to 6000 Seconds

Main Control Functions

Soft Stall (Automatic Load Reduction Control During Overload)

Restart into Rotating Motor

Main Protective Functions Current Limit, Overcurrent, Overcharge, Overload, Undervoltage, Overvoltage, Ground Fault, CPU Error, Abnormal Cooling Fan

Data Transmission Ethernet, Optional Probus, Modbus RTU, Modbus, TCP/IP, TOSLINE-S20, and DeviceNet Available

Overload Ratio 115% FLA for 60 Seconds (2000 HP, 4160 V, 110%)*

Interface

Liquid Crystal Display/

Electronic Operator

(LCD EOI )

4 x 20 Graphical Backlit LCD Display; Ability to Display Multiple Parameters on One Screen; Flash-Upgradeable Software Includes Multi-Function Ro tary Encoder

and Ethernet PC Interface

LED Indications Run (Red)/Stop (Green), Remote/Local, Indication of Inverter Status

Keys Local/Remote, Monitor/Program, Run, Enter, ESC, Stop/Reset, Up, Down

Push Button Illuminated Interlock and Fault Reset Push Buttons

Analog Outputs Eight Selectable Voltage or Current Output Signals with Programmable Functions

Analog Inputs Two Selectable Voltage or Current Input Signals

Digital Inputs Eight Digital Inputs with Programmable Functions

Digital Outputs Six Available Digital Outputs with Programmable Functions (One Internal to Drive)

Construction

Enclosure NEMA 1, IP20, IEC-529, Gasketed and Filtered

Panel Construction Free-Standing, Front Maintenance Type, Top or Bottom Access for Motor and Power Cables

Cooling Forced-Air Cooled with Optional Redundant Fans

Color ANSI-61 Gray

Ambient Conditions

Ambient Temperature 0 to 40˚; 32 to 104˚F

Humidity Maximum 95% (Non-Condensing)

Altitude 1000 Meters Above Sea Level or Less

Installation Indoor, No Direct Sunlight, Protect from Corrosive Gases, Explosive Gases

Typical Applications Fan, Blower, Pump, Compressor, Extruder, Options for Submersible Pumping Applications

Standards Electrical Performance: NEC, ANSI

Components and Others NEC, NEMA, UL

**Typical HP Rating of 4-Pole Motor; Contact Factory for Applications on Constant Torque Loads