12

PHASER 8560 EVALUATOR GUIDE

SECTION 3

Solid Ink Technology

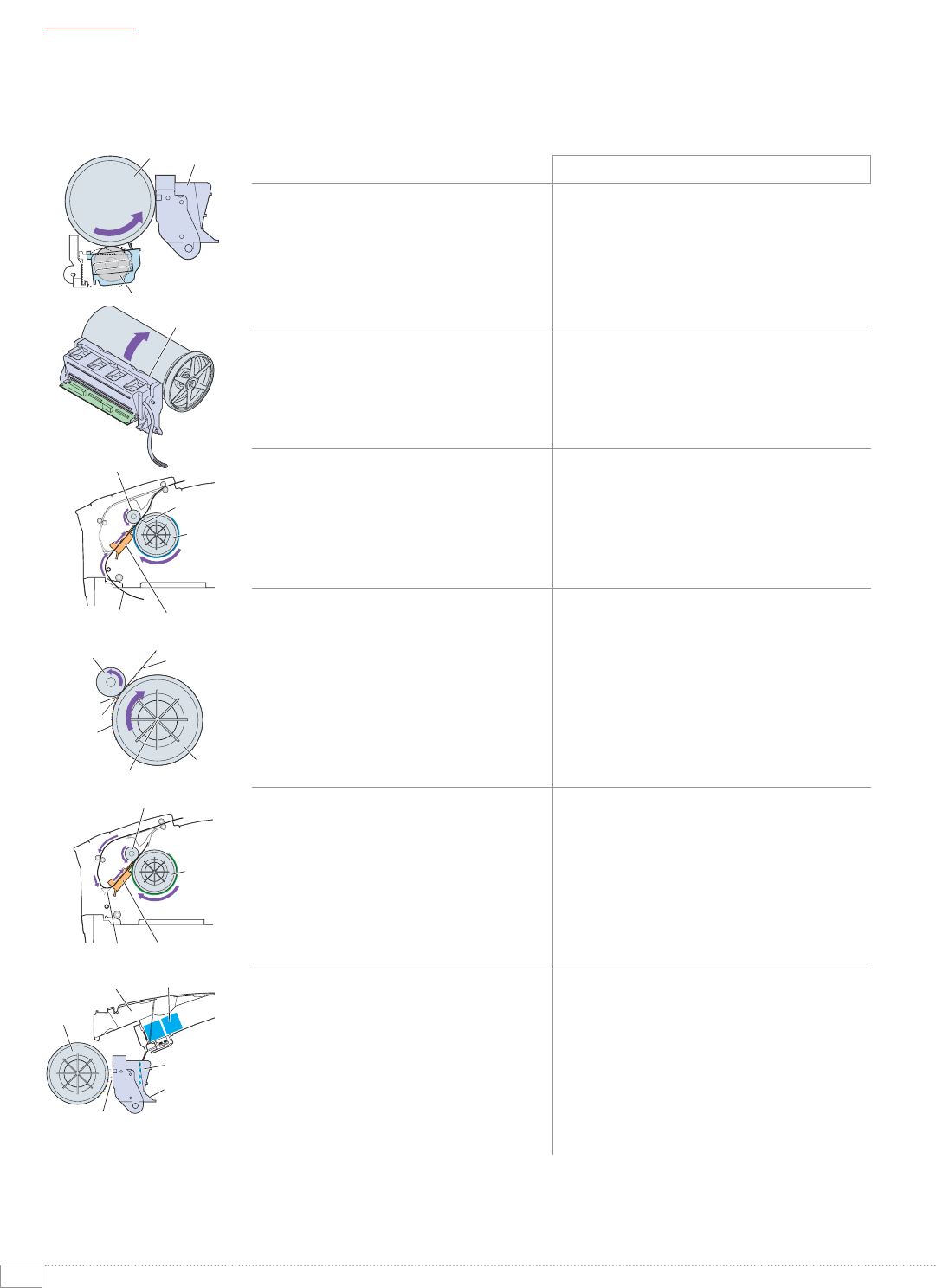

INSIDE A SOLID INK COLOUR PRINTER

Printhead

Transfix roller

Image transfer

Cooled solid

ink on paper

Drum

Drum heater

Heated, soft

ink on drum

Preheater

Transfix roller

Sheet of paper

Drum

Ink stick

Ink loader

Printhead

Ink reservoir

Ink jets

Drum

Drum

Printhead

Maintenance roller

Sheet of paper

Preheater

Transfix roller

Image transfer

from drum

to paper

Drum

Preparing to print. As the printing process

begins, the long-life maintenance roller

quickly applies a microscopic layer of

silicone oil to the heated drum for reli-

able ink release.

Single pass imaging. Next, the full-width

printhead applies all colours at the same

time on the rotating drum.

Image transfer. A sheet of paper is rapidly

fed between the drum and a transfix

roller, transferring the ink to the paper.

Ink bonding. As the ink on the drum

transfers to the paper, it penetrates the

paper’s fibers, but without the spreading

of liquid inkjets or the toner scattering of

lasers. The ink cools and solidifies imme-

diately, forming a strong, permanent

bond to the paper.

Two-sided printing. For automatic two-

sided printing, the paper is not fully

ejected into the exit tray but is fed back

into the printer through the duplex paper

path. The second image on the drum is

transferred to the other side of the paper.

Reloading. The ink loader draws ink

from solid ink sticks instead of a self-

contained toner cartridge. Ink can be

replaced or added at any time without

taking the printer offline.

• A simple, robust, reliable printing mechanism

• Maintenance roller lasts up to 30,000 prints

(8560 Extended Maintenance Kit only)

• No complex consumables

• High-speed image transfer

• Simultaneous application of all colours

eliminates misregistration of separate cyan,

magenta, yellow, and black image layers

• High-speed image transfer

• A short, simple paper path for speed and

high reliability

• Transfer printing process yields great print

quality on a wide variety of paper types

• No fuser required

• Colourfast printing with no smearing

or drying time

• More consistent colour quality on a

wider range of media than liquid inkjet

or colour laser

• A simple, short, built-in duplex paper

path means faster two-sided printing

and fewer paper jams

• No additional paper tray required

• Easy, on-the-fly ink stick reloading for

continuous operation

• Ink loader can be “topped off” before long,

high-coverage print jobs to avoid interruptions

• More environmentally friendly; less wasteful

packaging, less waste ink by-products

ADVANTAGES