37 Sp

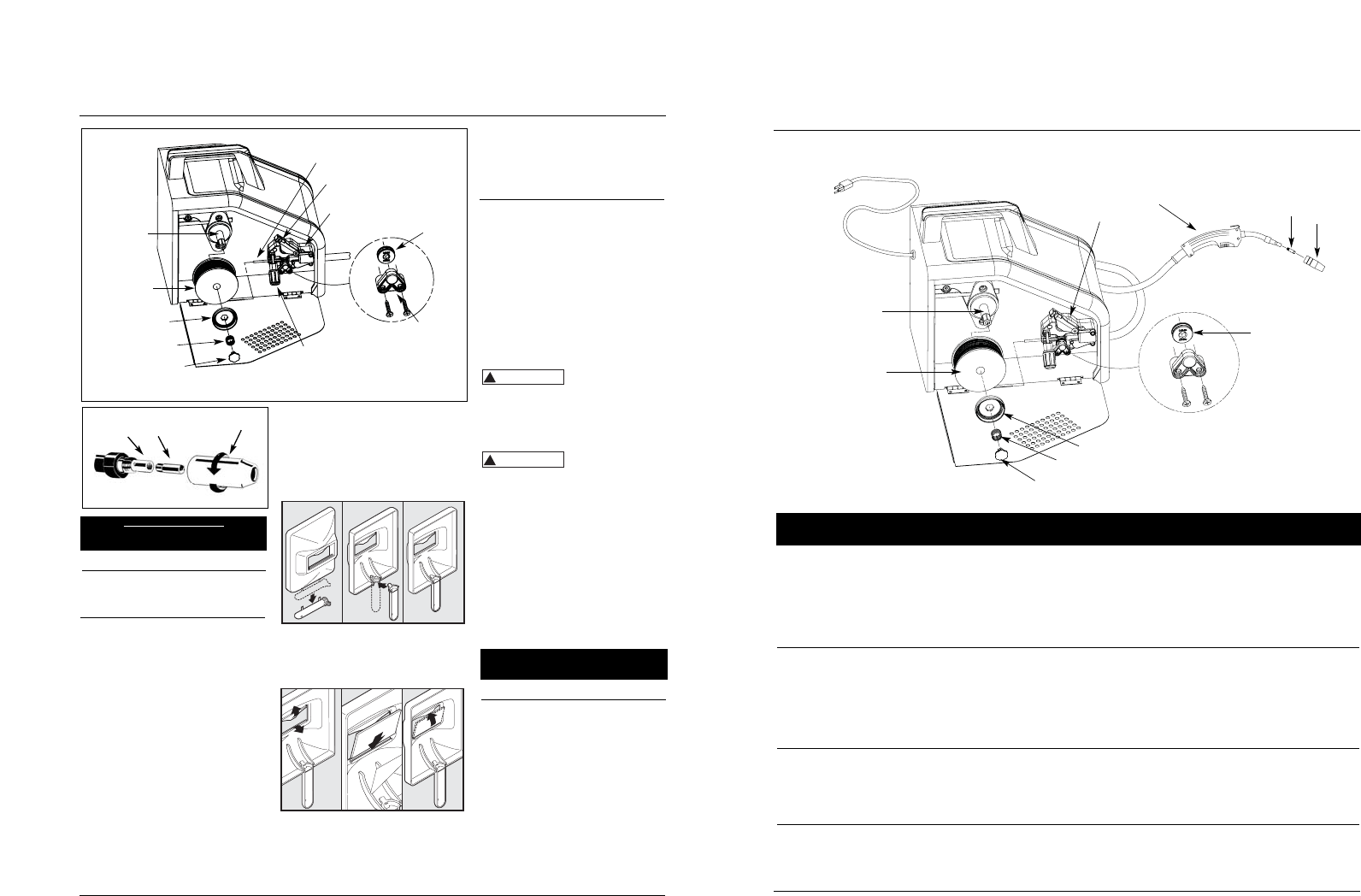

Modelos WF2050, WF2054, WF2057 & WF2058

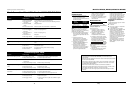

5

1

2

3

4

9

8

7

6

10

Figure 12 - Modèlos WF2050, WF2054,

WF2057 & WF2058

No. de Ref. Descripción No. del repuesto Ctd.

1 Ensamble de soplete y manguera (fundente revestido, 2,44 m, WF2050 & WF2057) WC403650AV 1

Ensamble de soplete y manguera (fundente revestido, 3,05 m, WF2054 & WF2058) WC404000AV 1

2 Punta de contacto - 0,035” (0,9 mm, 3,05 m, WF2054 & WF2058) WT501400AV 1

Punta de contacto opcional – 0,030” (0,8 mm) Paquete de 4 WT501300AJ †

Punta de contacto opcional – 0,035” (0,9 mm) Paquete de 4 WT501400AJ †

3 Boquilla WT502100AV 1

4 Portabobinas WC500805AV 1

5 Ensamble de la placa de conducción WC500800AJ 1

6 Vástago y rejilla WC707018AV 1

7 Retén de la bobina WC707024AV 1

8 Resorte del retén de la bobina WC707026AV 1

9 Anillo del retén de la bobina WC707023AV 1

10 Alambre de soldar c/fundente – 0,030” (0,8 mm) Bobina de 2 lb (0,9 kg) (E71T-GS) WE200001AV †

Alambre de soldar c/fundente – 0,030” (0,8 mm) Bobina de 10 lb. (4,54 kg) (E71T-GS) WE201000AV †

Alambre de soldar c/fundente – 0,035” (0,9 mm) Bobina de 2 lb. (0,9 kg) (E71T-GS) WE200501AV †

Alambre de soldar c/fundente – 0,035” (0,9 mm) Bobina de 10 lb. (4,54 kg) (E71T-GS) WE201500AV †

11 ▲ Máscara de mano (no se incluyen lentes) (WF2050 & WF2058) WC801700AV 1

12 ▲ Lentes oscuros (para máscara de mano) (WF2050, WF2054 & WF2058) WC801100AV 1

13 ▲ Martillo/cepillo cincelador WC803400AV 1

14 ▲ Etiqueta adhesiva de seguridad DK688509AV 1

15 ▲ Pinza de tierra (WF2050) WC100300AV 1

▲ Pinza de tierra (WF2054, WF2057 & WF2058) WC100600AV 1

16 ▲ Guantes para soldar (sólo WF2054, WF2057 & WF2058) WT200501AV 1

17 ▲ Casco de soldar (sólo WF2057) WT100500AV 1

▲ No se muestran

† Accesorio opcional

HANDSHIELD

1. Cut detachable handle (WF2050,

WF2054 & WF2058 only; WF2057 is

supplied with a fully assembled

helmet) away from shield. Trim the

excess plastic to remove sharp edges

(See Figure 4).

2. To attach the handle, place shield on

a flat surface and press handle into

place (See Figure 4).

3. Insert filter lens exactly as shown in

Figure 5.

NOTE: If you have never welded before

or have little experience, a full face

4

Operating Instructions and Parts Manual

Assembly (Continued)

DUTY CYCLE / THERMOSTATIC

PROTECTION

Welder duty cycle is the percentage of

actual weld time that can occur in a ten

minute interval. For example, at a 20%

duty cycle, actual welding can occur for

two minutes, then the welder must cool

for eight minutes.

Internal components of this welder are

protected from overheating with an

automatic thermal switch. A yellow

lamp is illuminated on the front

panel if the duty cycle is exceeded.

Welding operations may continue when

the yellow lamp is no longer illuminated.

POLARITY

This welder is configured for DCEN, direct

current electrode negative.

helmet is recommended. Both hands

are needed to stabilize and control the

angle and arc length of the electrode.

Operation

1. Be sure to read, understand, and

comply with all precautions in the

General Safety Information section.

Be sure to read the entire section

entitled Welding Guidelines prior to

using this equipment.

2. Turn welder off.

3. Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other

contaminants. These contaminants

make welding difficult and cause

poor welds.

All persons

operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including: eye

protection with proper shade, flame

resistant clothing, leather welding

gloves, and full foot protection.

If heating,

welding, or cutting

materials that are galvanized, zinc

plated, lead, or cadmium plated refer to

the General Safety Information Section

for instructions. Extremely toxic fumes

are created when these metals are

heated.

4. Connect the work clamp to the work

piece or workbench (if metal). Make

sure the contact is secure. Avoid

surfaces with paint, varnish,

corrosion, or non-metallic materials.

5. Position the Heat Selector on the

front panel to the desired setting

(See decal inside wire feed

compartment).

NOTE: These settings are general

guidelines only. Heat setting may vary

according to welding conditions and

materials.

6. Rotate the Wire Speed Control to

setting number 5 to start with, then

adjust as needed after test weld.

7. Plug the input cord into a proper

voltage receptacle with proper

circuit capacity (See circuit

requirements on front page).

!

WARNING

!

WARNING

Contact Tip Markings

Mark Wire Size

0.8 mm 0.030”

0.9 mm 0.035”

www.chpower.com

Torch

Diffuser

Contact Tip

Nozzle

Figure 3 - Torch Nozzle

Spindle

Welding wire

Tensioner ring

Tension spring

Retainer

Tensioner knob

Guide tube

Tensioner arm

Drive deck

Roller

support

Drive

roller

Figure 2 - Weld Wire Routing

Figure 4

Figure 5

Metal Heat

Thickness Setting

14 - 18 Gauge Low

Thicker Than 14 Gauge High