34 Sp

Manual de Instruccones y Lista de Repuestos

7

air from reacting with the molten metal.

Once the weld cools to the point that it

is no longer glowing red, the slag can be

removed. Removal is done with a

chipping hammer. Lightly tap the slag

with the hammer and break it loose

from the weld bead. The final clean-up is

done with a wire brush. When making

multiple weld passes, remove the slag

before each pass.

WELDING POSITIONS

Four basic welding positions can be used;

flat, horizontal, vertical, and overhead.

Welding in the flat position is easier than

any of the others because welding speed

can be increased, the molten metal has

less tendency to run, better penetration

can be achieved, and the work is less

fatiguing. Welding is performed with

the wire at a 45º travel angle and 45º

work angle.

Other positions require different

techniques such as a weaving pass,

circular pass, and jogging. A higher skill

level is required to complete these welds.

Overhead welding is the least desirable

position as it is the most difficult and

dangerous. Heat setting and wire

selection will vary depending upon the

position.

All work should be performed in the flat

position if possible. For specific

applications, consult an arc welding

technical manual.

WELD PASSES

Sometimes more then one pass is

necessary to fill the joint. The root pass is

first, followed by filler passes and the

cover pass (See Fig. 8). If the pieces are

thick, it may be necessary to bevel the

edges that are joined at a 60º angle.

Remember to remove the slag before

each pass.

PUSH VS PULL TECHNIQUE

The type and thickness of the work piece

dictate which way to point the gun

nozzle. For thin materials (18 gauge and

up), the nozzle should point out in front

of the weld puddle and push the puddle

across the workpiece. For thicker steel,

the nozzle should point into the puddle

to increase weld penetration. This is

called backhand or pull technique (See

Figure 10).

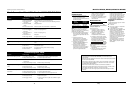

Figure 8 - Fillet Welds (60˚ Bevel)

Models WF2050, WF2054, WF2057 & WF2058

Welding Guidelines (Continued)

Cover

Root

Filler

www.chpower.com

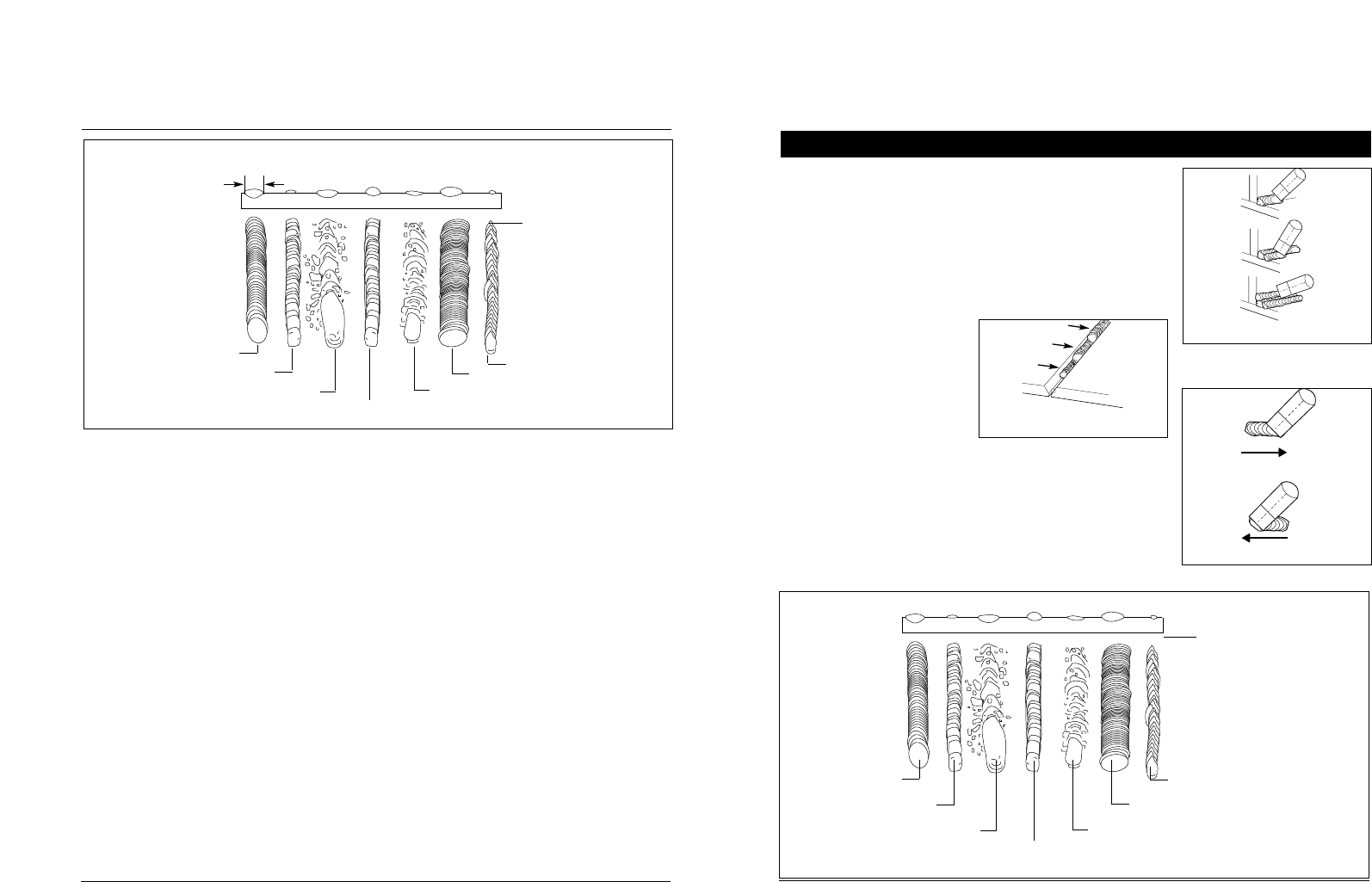

PULL

Figure 10

Figure 9 - Multiple Weld Passes

PUSH

Wire speed too fast

Heat too high

Wire speed too slow

Heat too low

Travel speed too low

Travel speed too fast

Normal heat, wire speed,

travel speed

Base metal

Figure 11 - Weld Appearance

Metal Básico

Figura 11 - Apariencia de la soldadura

Velocidad de alimentación muy rápida

Corriente muy alta

Velocidad de desplazamiento muy lenta

Corriente muy baja

Velocidad muy lenta

Velocidad muy rápida

Corriente, velocidad de

alimentación y velocidad de

desplazamiento normales

A

Nota: El ancho (A) del

reborde debe ser

aproximadamente el doble

del diámetro de la varilla de

electrodo que se use.