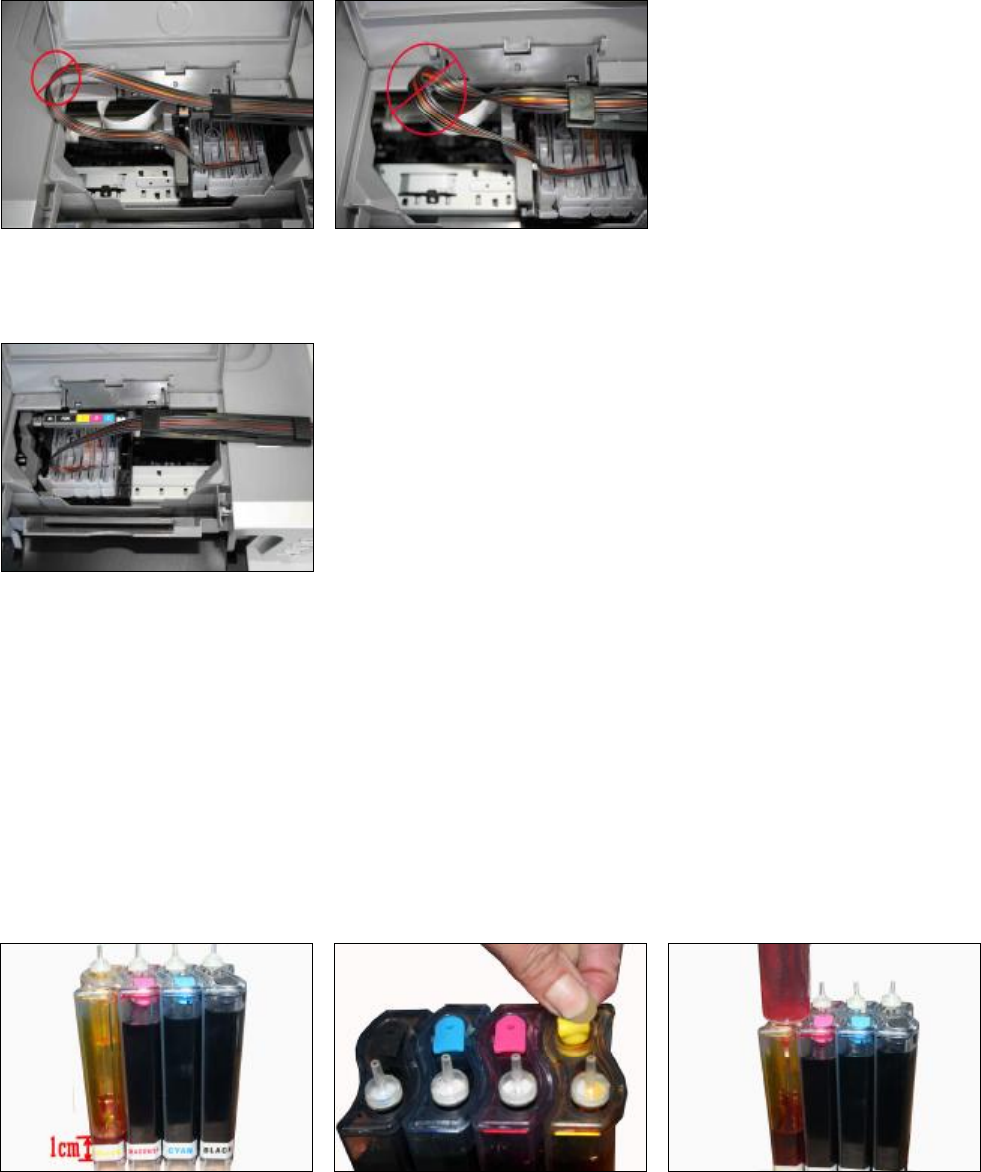

Improper Situation:

1.Too long Tube 2. Twisted Tube

Proper Situation:

Step 6: Check the Nozzle

Broken lines may be caused by the air inside the nozzle. After repeating cleaning

printer head, if there is still broken lines, especially when the individual color has

only 1 broken line, then there is no need of continuous cleaning. Just leave the printer

stay there for about 1 hour, and this problem may be solved. If the nozzle check is

still not OK, then pls contact us.

III Refill Ink

1. Pls note the left ink in the ink 2. Pull out the Rubber Plug 3. Refill ink according to the colors.

tank. If the left ink is less than carefully. After filling, pls recover the rubber

1 cm, pls add ink in time. plug in the ink filling hole.

Pls keep the ink tanks and the printer on the same level.

Notice:

1. During normal use, pls do not take out the inner cartridges freely.

2. During printing, pls do not invert the ink tanks. Pls keep the ink tanks on the same level

with the printer.

3. Use the CISS in 15℃-35℃ environment.

4. When refill ink, suggesting using our ink, in order to ensure the printing quality.