November 21, 2002 Document No. 001-43117 Rev. ** 4

AN1196

This figure shows the dielectric material thickness (“Prepreg”)

between layers 1 and 2 and the thickness between layers 3

and 4. The dimensions between these layers are a key ele-

ment in the design to set the proper characteristic impedance

for the USB data traces. This is the “h” term mentioned in the

prior section on PCB impedance design. The core material of

the PCB lies between layer 2 and 3. Although this material is

not critical to impedance characteristics, it is used to deter-

mine the overall board thickness.

Split Planes and Signal Routing

The shield/safety ground is on one of the four layers of the

PCB. However, when viewed across all layers of the PCB,

the section with the shield/safety ground plane should not

overlap any other planes or signals. If the shield/safety

ground is on the edge of the board with the USB connectors,

then there should not be any other metal in other PCB layers

directly above or below that area.

An alternate method of isolating the shield from the signal

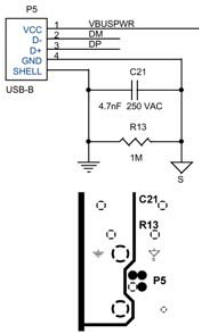

ground is shown is Figure 4. The lower section of Figure 4

illustrates a portion of the ground layer. Given this scenario,

shield/safety ground plane is on the same layer as the signal

ground plane and is associated with the PCB’s layer two.

Figure 4. Section of Split Ground Plane

The upper portion of Figure 4 shows the schematic associ-

ated with the coupling across a split plane using C21 and

R13 components. The width of the gap between the

shield/safety ground and the signal ground should be no less

than 25 mil in order to minimize electrical edge coupling.

It is not necessary to have a large shield/safety ground plane.

A 100-mil-wide trace for interconnect is sufficient.

The following is a list of routing requirements which should be

adhered to:

■ USB connector pins 1, 2, 3, and 4 are in the area of the

signal ground, not the shield/safety ground.

■ The USB signals traces from the connector route over the

signal ground plane, never over the shield/safety ground.

■ No signal should route over the shield/safety ground

plane.

■ No other power or signal ground planes should overlap

the shield/safety ground plane.

■ All USB data signals should be routed exclusively on layer

one, the top side.

■ They should not route underneath any component except

for their associated USB connector.

■ Line length should be minimized.

■ To minimize coupling between the USB data pair and other

non-USB signals, the USB data pair should not be closer

than 35 mil to another signal.

■ If a ground fill is to be used on the top side of the board,

then to avoid significant impact to signal impedance, the

USB data pair should not be within 35 mil of the surface

ground plane.

These guidelines also apply to the crystal used for the

CY7C68013.

USB data lines must maintain proper differential pairing. This

is not possible at either end of the trace. At either end of the

trace, the physical limitation of routing to the pins of the USB

connector and the CY7C68013 causes a divergence from

this.This divergence should be minimized and the signal pairs

should adhere to the proper trace design for the required 90-

ohm differential impedance.

Thermal Design Considerations

The QFN (Quad Flatpack No leads) is a package with a small

footprint and low profile. It has excellent thermal properties: a

very low Θ

ja

of approximately 25°C per watt. These thermal

properties are ideal for the high-performance FX2.

The appropriate thermal design for use with the EZ-USB FX2

is to dissipate heat from the QFN package by conduction, not

convection. Heat is conducted away from the package

through its bond to the PCB. From there it is dissipated into

the signal ground plane. Special attention to the heat transfer

area below the package is required.

On the bottom of the package is a metal pad referred to as

the exposed die attach paddle, (or simply exposed paddle).

The exposed paddle is the means by which most of the EZ-

USB FX2 thermal energy is dissipated away from the pack-

age. The exposed paddle is a square metal area approxi-

mately 6 mm on a side.

[+] Feedback [+] Feedback