DS_DNM04SMD10_07162008

8

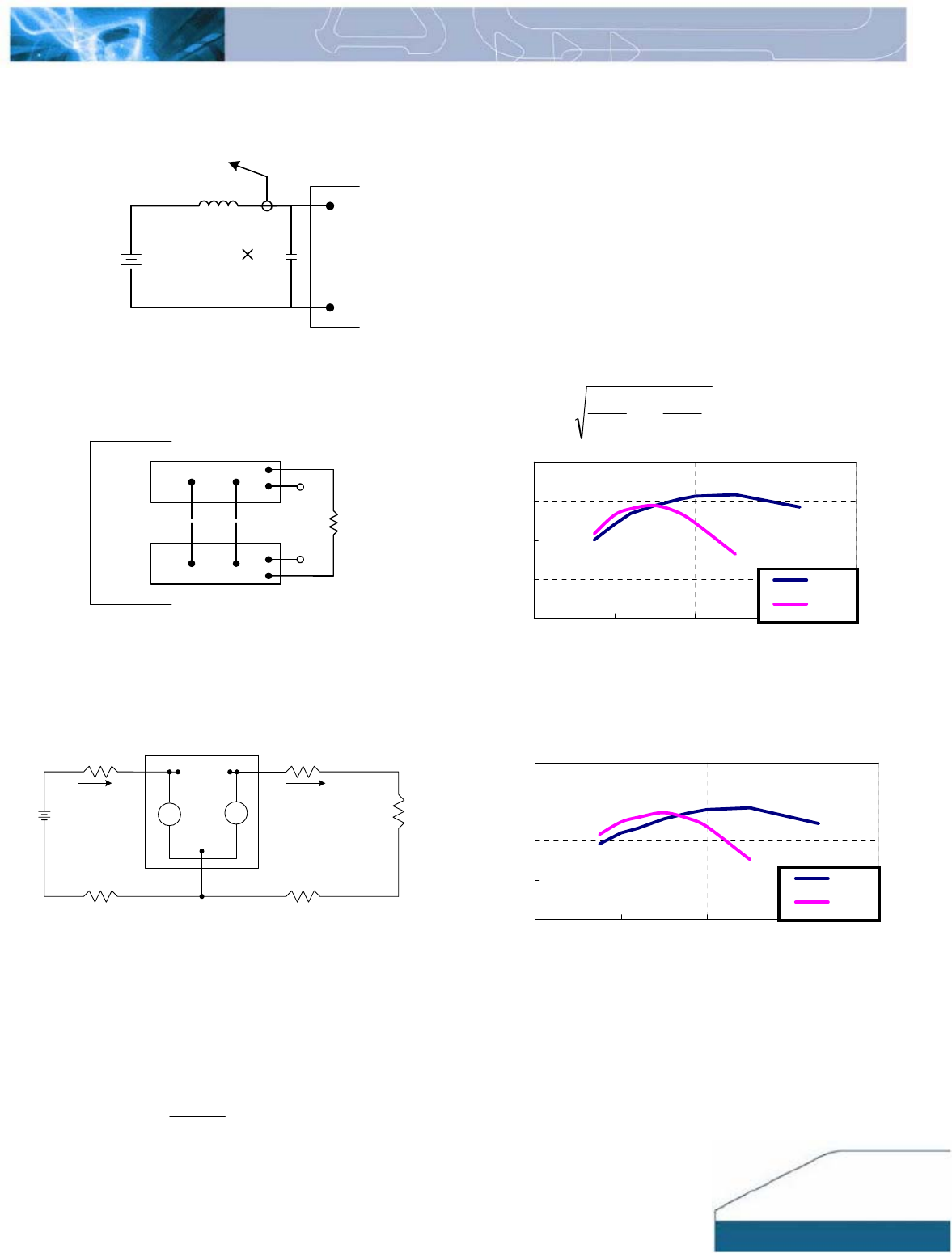

TEST CONFIGURATIONS

V

I

(+)

V

I

(-)

BATTERY

2

100uF

Tantalum

L

TO OSCILLOSCOPE

Note: Input reflected-ripple current is measured with a

simulated source inductance. Current is measured at

the input of the module.

Figure 29: Input reflected-ripple test setup

Vo

GND

COPPER STRIP

10uF

tantalum

1uF

ceramic

SCOPE

Resistive

Load

Note: Use a 10μF tantalum and 1μF capacitor. Scope

measurement should be made using a BNC cable.

Figure 30: Peak-peak output noise and startup transient

measurement test setup.

SUPPLY

I

I

V

I

Vo

GND

Io

LOAD

CONTACT AND

DISTRIBUTION LOSSES

CONTACT RESISTANCE

Vo

Vin

Figure 31: Output voltage and efficiency measurement test

setup

Note: All measurements are taken at the module

terminals. When the module is not soldered (via

socket), place Kelvin connections at module

terminals to avoid measurement errors due to

contact resistance.

%100)( ×

×

×

=

IiVi

IoVo

η

DESIGN CONSIDERATIONS

To maintain low noise and ripple at the input voltage, it is

critical to use low ESR capacitors at the input to the

module. Figure 32 shows the input ripple voltage (mVp-p)

for various output models using 200 µF(2 x100uF) low

ESR

tantalum capacitor (KEMET p/n: T491D107M016AS,

AVX p/n: TAJD107M106R, or equivalent) in parallel with

47 µF ceramic capacitor (TDK p/n:C5750X7R1C476M or

equivalent). Figure 33 shows much lower input voltage

ripple when input capacitance is increased to 400 µF (4 x

100 µF)

tantalum capacitors in parallel with 94 µF (2 x 47

µF) ceramic capacitor.

The input capacitance should be able to handle an AC

ripple current of at least:

Arms

Vin

Vout

Vin

Vout

IoutIrms

⎟

⎠

⎞

⎜

⎝

⎛

−= 1

0

50

100

150

200

01234

Output Voltage (Vdc)

Input Ripple Voltage (mVp-p)

5.0Vin

3.3Vin

Figure 32: Input voltage ripple for various output models, IO =

10 A (CIN = 2

×

100 µF tantalum // 47 µF ceramic)

0

50

100

150

200

01234

Output Voltage (Vdc)

Input Ripple Voltage (mVp-p)

5.0Vin

3.3Vin

Figure 33: Input voltage ripple for various output models, IO =

10 A (CIN = 4

×

100 µF tantalum // 2

×

47 µF ceramic)