INSTALLATION (continued)

1 --- 2

Engine Starting Contacts

Customer connections for engine control contact

connections are located on the transfer switch. Refer

to wiring diagram provided with the Series 300 ATS

and connect the engine start wires to the appropriate

term inals. See Figur e 1–2 and Tabl e A.

Table A. Engine start connections.

When normal source

fails

Terminals on transfer

switch

contact closes TB14 and TB15

contact opens TB14 and TB16

TB 14

TB 15

TB 16

ENGINE STARTING CONTACTS

( SHOWN DE–ENERGIZED )

TOP

STUD

MIDDLE

STUD

BOTTOM

STUD

14

15

16

TS

NR

NR

left side

of switch

Figure 1–2. Engine starting contact label and

terminals located on the transfer switch.

Controller Ground

A grounding wire must be connected to the controller’s

lower left mounting stud. Because the controller is

mounted on the enclosure door, a conductive strap

must be used between the enclosure and the door.

This connection provides proper grounding which does

not rely upon the door hi nges.

Harnesses

The transfer switch is connected to the left side of the

controller by a plug–in harness (two plugs).

Auxiliary Circuits

Connect auxiliary circuit wires to appropriate terminals

on transfer switch as shown on the wiring diagram

provided with this Series 300 Automatic Transfer

Switch. Make the necessary auxiliary connections by

referring to Section 5, Control Features.

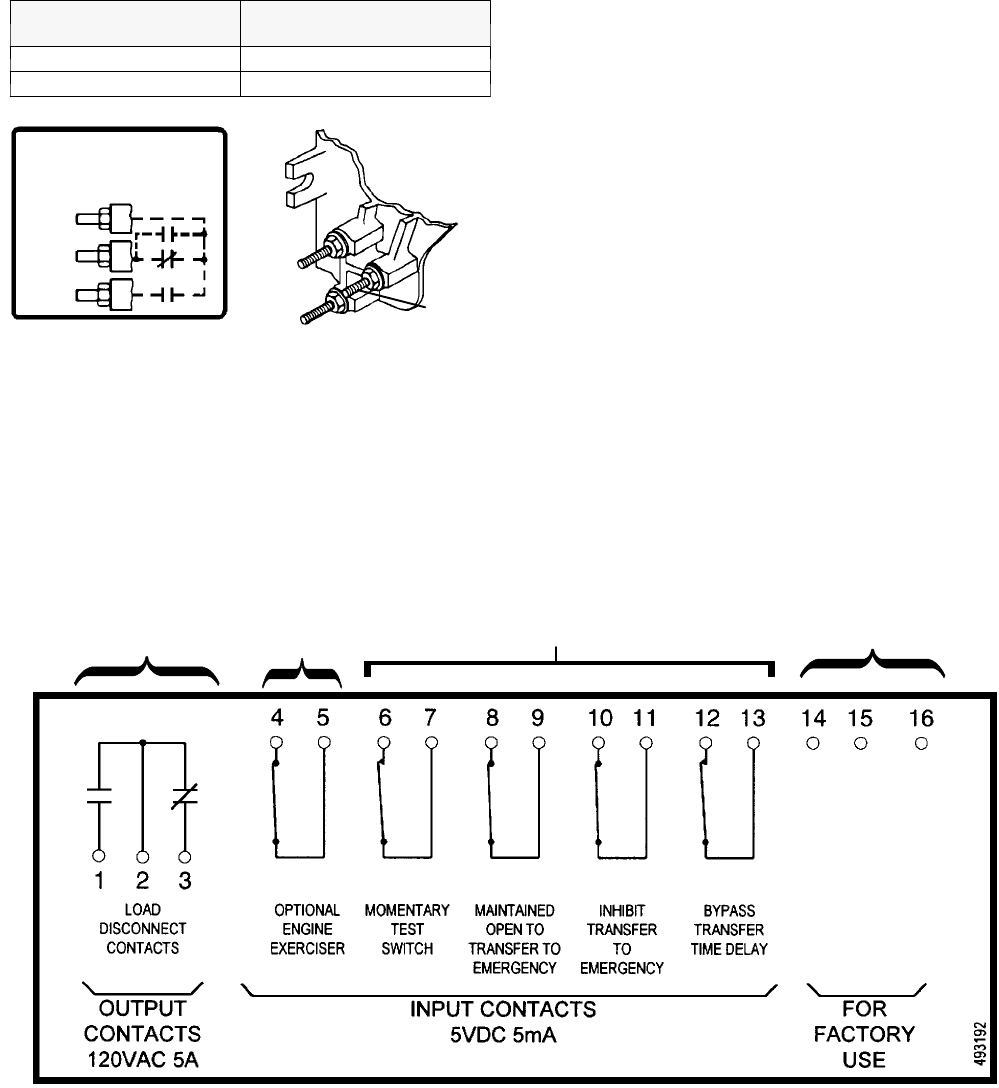

Connections to Controller for other Control Features

(located on bottom of Controller)

for factory

use only

Remote Control Features Connections

(refer to the Wiring Diagram &

page 5–4 for DIP switch settings)

Each control contact must be suitable

for a 5 V DC low energy circuit.

Programmable

Engine Exerciser

connection,

if provided

(refer to

page 5–2)

Load Disconnect

Feature

Connections

(see Wiring Diagram

& refer to page 5–4

for DIP switch settings)

Figure 1–3. Input / output label on the Controller showing possible connections to the lower terminal block.