© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 12

FPF2300/02/03 — Dual-Output Current Limit Switch

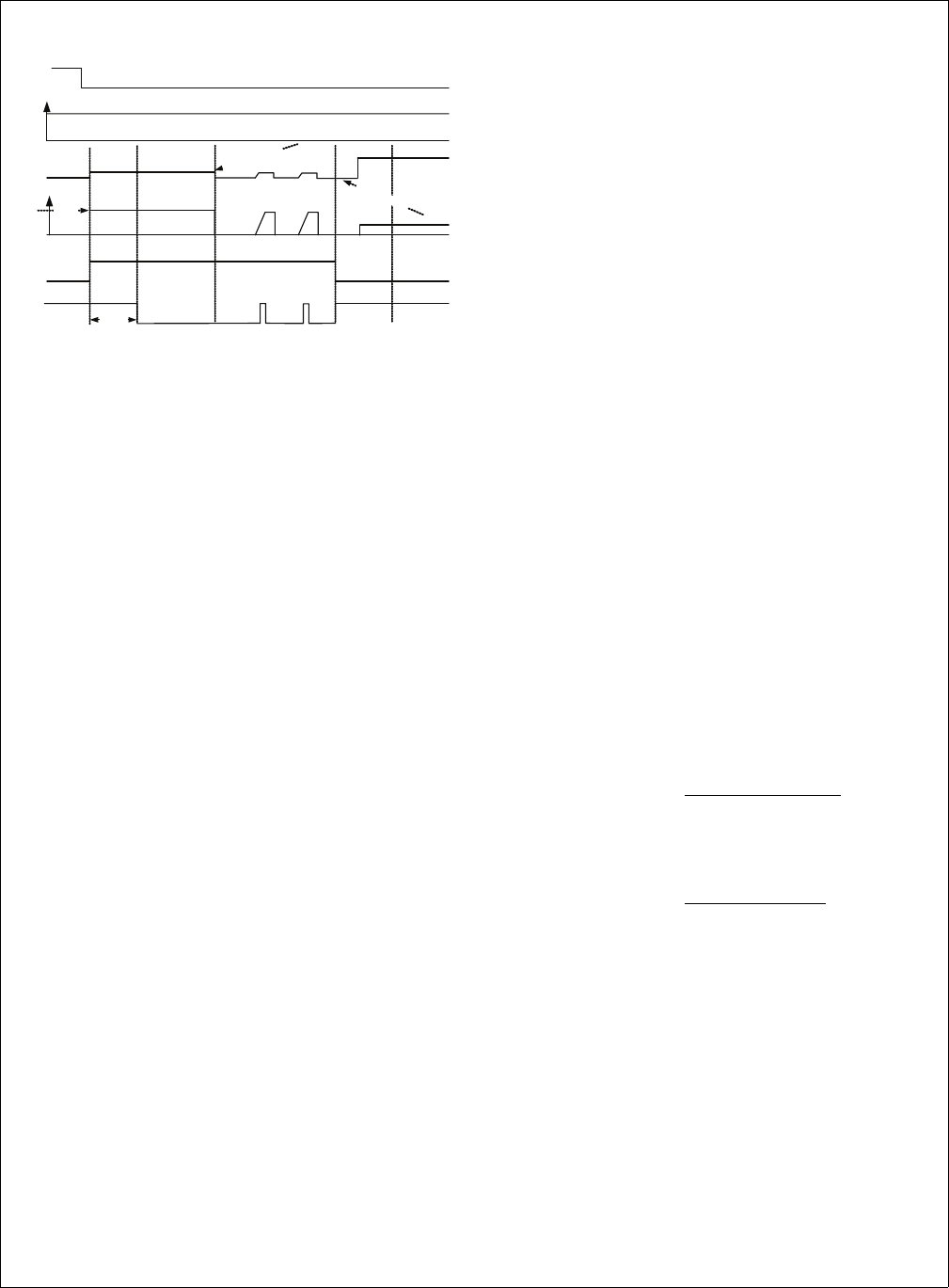

Figure 37. FPF2300 FLAGB While and Over-Current

Condition is Applied

Note:

7. An over-current condition signal loads the output with a

heavy load current larger than I

LIMIT

value.

Under-Voltage Lockout (UVLO)

The under-voltage lockout feature turns off the switch if the

input voltage drops below the under-voltage lockout threshold.

With the ON pin active (ON pin pulled LOW), the input voltage

rising above the under-voltage lockout threshold causes a

controlled turn-on of the switch and limits current overshoot. If a

device is in UVLO condition, both FLAGBs go LOW and indicate

the fault condition. The device detects the UVLO condition when

input voltage goes below UVLO voltage, but remains above

1.3V (typical).

Reverse Current Blocking

Each switch of FPF2300/2/3 has an independent reverse

current blocking feature that protects input source against

current flow from output to input. For a standard USB power

design, this is an important feature that protects the USB host

from being damaged due to reverse current flow on V

BUS

. To

activate the reverse current blocking, the switch must be in OFF

state (ON pins inactivated) so that no current flows from the

output to the input. The FLAGB operation is independent of the

reverse current blocking and does not report a fault condition if

this feature is activated.

Thermal Shutdown

The thermal shutdown protects the device from internally or

externally generated excessive temperatures. Each switch has

an individual thermal shutdown protection function and operates

independently as adjacent switch temperatures increase above

140°C. If one switch is in normal operation and shutdown

protection of second switch is activated, the first channel

continues to operate if the affected channel's heat stays

confined. The over-temperature in one channel can shut down

both switches due to rapidly generated excessive load currents

resulting in very high power dissipation. Generally, a thermally

improved board layout can provide heat sinking and allow heat

to stay confined and not affect the second switch operation.

During an over-temperature condition, the FLAGB is pulled

LOW and the affected switch is turned off. If the temperature of

the die drops below the threshold temperature, the switch

automatically turns on again. To avoid unwanted thermal

oscillations, a 10°C (typical) thermal hysteresis is implemented

between thermal shutdown entry and exit temperatures.

If output of both switches are connected together and an

excessive load current activates thermal protection of both, the

controller can shut down the switches after both FLAGB outputs

go LOW and turn on both channels again. This provides

simultaneous switch turn on. Thermal protection is for device

protection and should not be used as regular operation.

Input Capacitor

To limit the voltage drop on the input supply caused by transient

inrush currents when the switch is turned on into discharged

load capacitors or a short-circuit; an input capacitor, C

IN

, is

recommended between IN and GND. The FPF2310/2/3/3L

features a fast current limit response time of 20μs. An inrush

current (also known as surge current) could occur during the

current limit response time while the switch is responding to an

over-current condition caused by large output capacitors. A

10μF ceramic capacitor, C

IN

, is required to provide charges for

the inrush current and prevent input voltage drop at turn on.

Higher values of C

IN

can be used to further reduce voltage drop.

Output Capacitor

A 0.1μF to 1μF capacitor, C

OUT

, should be placed between the

OUT and GND pins. This capacitor prevents parasitic board

inductances from forcing output voltage below GND when the

switch turns off. This capacitor should have a low dissipation

factor. An X7R MLCC (Multilayer Ceramic Chip) capacitors is

recommended.

For the FPF2300 and FPF2302, the total output capacitance

needs to be kept below a maximum value, C

OUT(MAX)

, to

prevent the part from registering an over-current condition

beyond the blanking time and shutdown. The maximum output

capacitance for a giving input voltage can be determined from

the following:

For example, in a 5V application, C

OUT(MAX)

can be determined

as:

VIN

ON

FLAGB

VOUT

Startup

tBLANK

ILOAD

ILIMIT

Over

current

condtion

Thermal Shutdown

Device Cools Off

(1)

C

OUT(MAX)

=

I

LIM(MIN)

x t

BLANK(MIN)

V

IN

(2)

C

OUT(MAX)(IN = 5V)

=

1.1A x 5ms

5

=

1.1mF