© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com

FPF2300/02/03 • Rev. 1.1.3 15

FPF2300/02/03 — Dual-Output Current Limit Switch

PCB Layout Recommendations

For the best performance, all traces should be as short as

possible. To be most effective, the input and output capacitors

should be placed close to the device to minimize the effects that

parasitic trace inductances may have on normal and short-

circuit operation. Using wide traces for IN, OUTs, and GND pins

helps minimize parasitic electrical effects and the case-to-

ambient thermal impedance.

Improving Thermal Performance

Improper layout could result in higher junction temperature and

triggering the thermal shutdown protection feature. This concern

is particularly significant for the FPF2303, where both channels

operate in constant current mode in the overload conditions and

during fault condition the outputs are shorted, resulting in large

voltage drop across switches. In this case, power dissipation of

the switch (P

D

= (V

IN

- V

OUT

) x I

LIM(MAX)

) could exceed the

maximum absolute power dissipation of part.

The following techniques improve the thermal performance of

this family of devices. These techniques are listed in order of

the significance of impact.

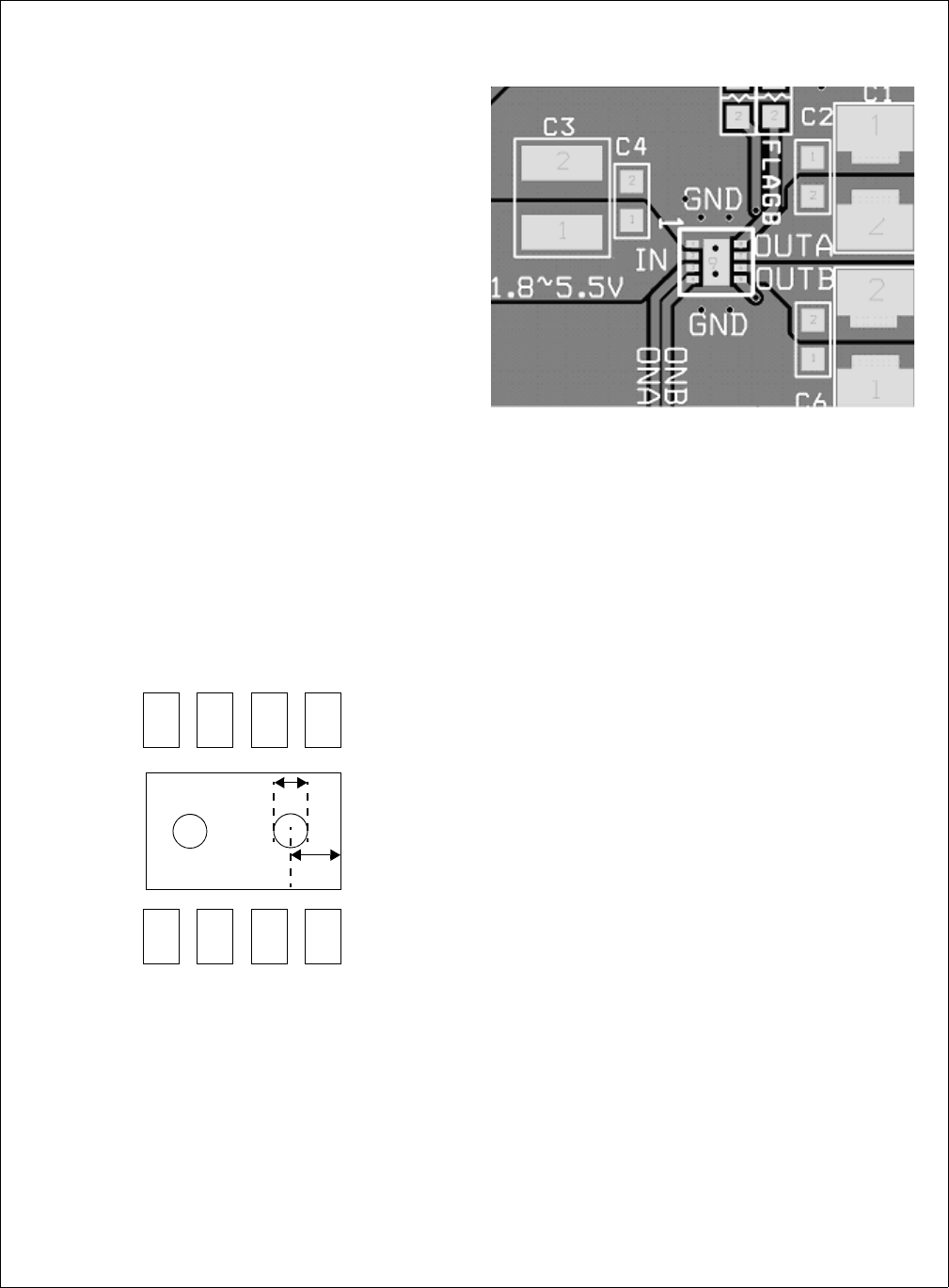

1. Thermal performance of the load switch can be improved

by connecting the DAP (Die Attach Pad) of MLP 3x3mm

package to the GND plane of the PCB.

2. Embedding two exposed through-hole vias into the DAP

(pin 9) provides a path for heat to transfer to the back GND

plane of the PCB. A drill size of round, 15 mils (0.4mm),

with 1-ounce copper plating is recommended to create

appropriate solder reflow. A smaller size hole prevents the

solder from penetrating into the via, resulting in device lift-

up. Similarly, a larger via hole consumes excessive solder

and may result in voiding of the DAP.

Figure 41. Two Through-Hole Open Vias Embedded

in DAP

3. The IN, OUTs, and GND pins dissipate most of the heat

generated during a high load current condition. Figure 42

illustrates a proper layout for devices in MLP 3x3mm

packages. IN, OUTs, and GND pins are connected to

adequate copper so heat may be transferred as efficiently

as possible out of the device. The low-power FLAGB and

ON pin traces may be laid out diagonally from the device to

maximize the area available to the ground pad. Placing the

input and output capacitors as close to the device as

possible also contributes to heat dissipation, particularly

during high load currents.

Figure 42. Proper Layout of Output and Ground

Copper Area

15mil

25mil